Author: Joey Wan

Author: Joey Wan  December 29,2021

December 29,2021

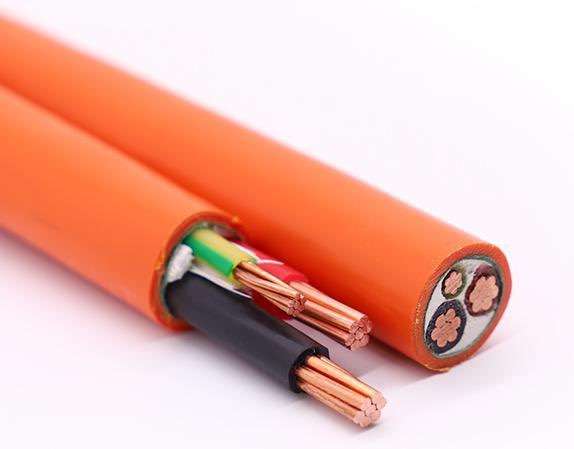

In the construction of urban power grids, XLPE insulated power cables have been widely used. Due to the particularity of the cable, there are special requirements for the laying, installation and other operations and maintenance of the cable. This article dedicated to help the buyers or project contractors procure more profitable and avoid purchasing the XLPE armoured cable without excellent quality.

Moisture or water ingress of the XLPE armoured cable will reduce the electrical resistivity of the cable insulation, which is an important factor in causing accidents in the operation of the cable line.

Causes and hazards of xlpe insulated power cable wading

1. As we all know, both ends of the xlpe armoured cable are sealed with plastic sealing sleeves when we purchase the xlpe insulated power cable from manufacturer or supplier. However, after a period of actual use at the construction site, the rest of the cables only need to be wrapped with plastic cloth to cover the fracture. Because they are generally placed in the open air, the airtightness is poor and the time is long. It is inevitable that moisture can penetrate into the xlpe insulated power cable. If it is a xlpe aluminium armoured cable, it will cause oxidation heavily influences the properties of cable.

2. When laying xlpe insulated power cables, often needed to cross roads, bridges and culverts. Due to weather or other reasons, there is often too much water in the xlpe armoured cable trenches. During the laying process, the cable heads will inevitably be immersed in water, and poor packaging or damage will cause water to enter the xlpe insulated power cable. In addition, when pulling wires and wiring, sometimes the outer sheath or even the armor layer will be scratched. This phenomenon is especially common when using mechanical traction.

3. After the xlpe armoured cable laying is completed, due to on-site construction conditions, the xlpe insulated power cable head cannot be remade in time, so that the unsealed cable fracture is exposed to the air or even immersed in water for a long time, causing a large amount of water vapor to enter the xlpe armoured cable.

4. In the process of making xlpe insulated power cable heads (including terminal heads and intermediate joints), the newly opened xlpe armoured cable heads may accidentally touch the water.

5. In the normal operation of the xlpe insulated power cable, if a failure occurs for some reason, the water in the cable trench will enter the cable through the insulation layer along the fault point. In civil buildings, especially on construction sites where large construction machinery is used, due to various human interventions, it is not uncommon for factors to cause xlpe armoured cable breakage or breakdown. When such an accident occurs, the cable insulation layer is severely damaged, resulting in more opportunities for the xlpe insulated power cable to be exposed to moisture.

Considering many purchasers and project contractors are searching for the specific xlpe cable size for reference when they decide to take a procurement plan, below a comprehensive xlpe cable size chart listed and help you can find the size you have been searching for. What's more all the sizes listed in below chart are available in JZD Cable and welcome to contact us for more information and we will reply on your inquiry less than 2 hours.

|

Nominal corss section mm2 |

Insulation thickness mm |

Sheath thickness mm |

Ovreall Diameter mm |

Weight Copper kg/km |

Weight Aluminum kg/km |

|

1x10 |

0.7 |

1.5 |

8 |

155 |

95 |

|

1x16 |

0.7 |

1.5 |

9 |

220 |

120 |

|

1x25 |

0.9 |

1.5 |

10 |

345 |

190 |

|

1x35 |

0.9 |

1.5 |

12 |

424 |

207 |

|

2x35 |

0.9 |

1.8 |

20.2 |

1006 |

556 |

|

2x50 |

1 |

1.8 |

22.2 |

1365 |

722 |

|

2x70 |

1.1 |

1.8 |

24.8 |

1872 |

972 |

|

2x95 |

1.1 |

1.8 |

27.4 |

2475 |

1253 |

|

3x95 |

1.1 |

2 |

34 |

3020 |

1240 |

|

3x120 |

1.2 |

2.5 |

38 |

3790 |

1540 |

|

3x150 |

1.4 |

2.5 |

42 |

4750 |

1940 |

|

4x150 |

1.4 |

3 |

46 |

6238 |

2571 |

|

4x185 |

1.6 |

3 |

51 |

7562 |

3091 |

|

5x240 |

1.7 |

3 |

68.8 |

13130 |

5570 |

|

3x50+1x25 |

1 |

2 |

28 |

1901 |

816 |

|

3x120+2x70 |

1.2 |

2.5 |

45.4 |

5437 |

2287 |

|

4x240+1x120 |

1.7 |

3 |

68.2 |

11567 |

4763 |

After water enters the power cables, it will often aging in future use, which will eventually lead to xlpe armoured cable breakdown, however we still can reduce the troubles that listed above. Buyers or project contractors, must pay attention when purchasing xlpe insulated power cables, it is very important to choose a reliable supplier.

Previous Post: How do find out where the wire and cable breakpoint is?

Next Post: How To Choose a Better H05VV-F Cable And Wire Companies?