Author: Joey Wan

Author: Joey Wan  September 20,2023

September 20,2023

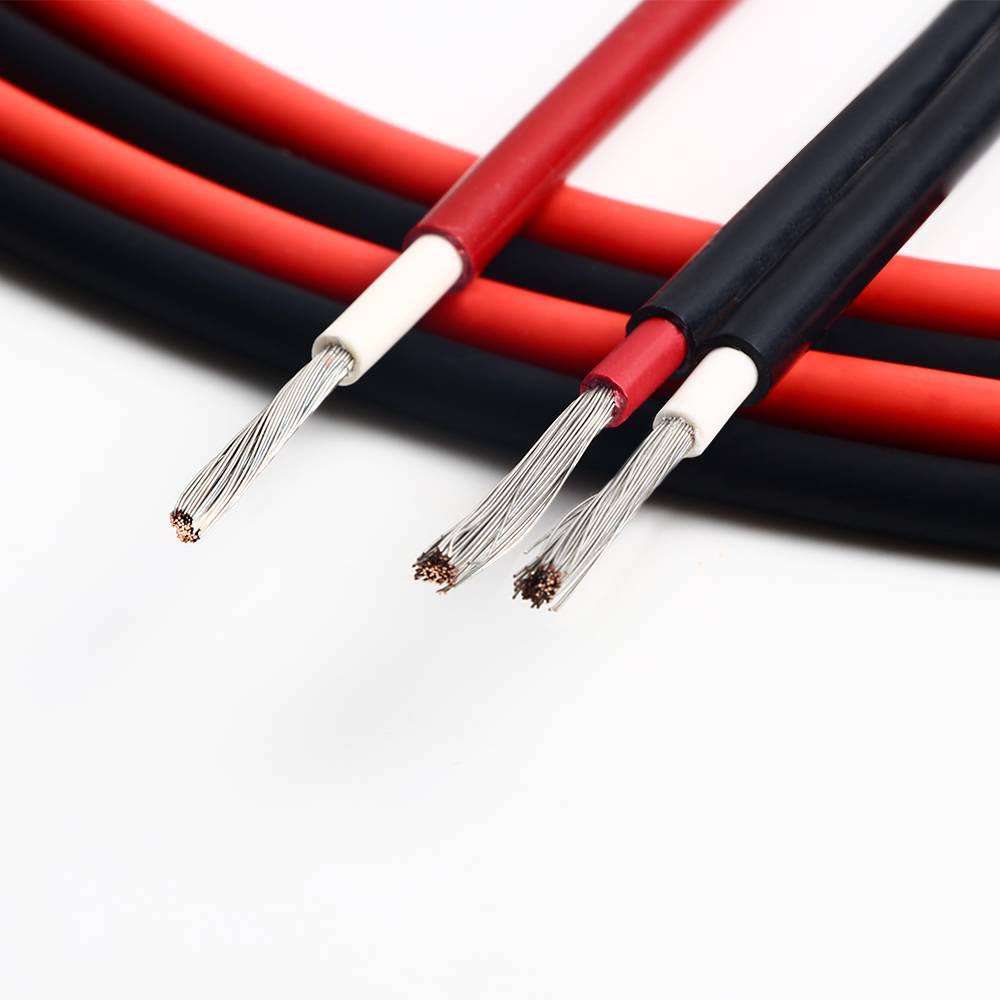

Most solar cables are made of tinned copper wire, which is a highly conductive material that is resistant to corrosion. It is also less prone to overheating than other types of wire, making it ideal for solar applications. The wires are typically insulated with XLPE, or cross-linked polyethylene, which also has excellent temperature resistance.

The insulation on solar cables is designed to handle high temperatures and prevent heat from escaping the cable. This is important because excess heat can damage the cable and reduce its efficiency. The insulation on solar cables is typically rated for temperatures up to 90 degrees Celsius, which is well within the operating range of most solar installations.

Some solar cables also have an insulated XLPE sheath, which provides an extra layer of protection against heat and abrasion. This is particularly important for cables that are exposed to sunlight and other weather conditions. The sheath helps prevent the cable from deteriorating and ensures its longevity.

While solar cables can generate heat, this is not necessarily a bad thing. In fact, it is a sign that the cable is working properly and efficiently. The key is to ensure that the cable and insulation are designed to handle the heat generated and prevent it from escaping.