Author: Joey Wan

Author: Joey Wan  September 09,2021

September 09,2021

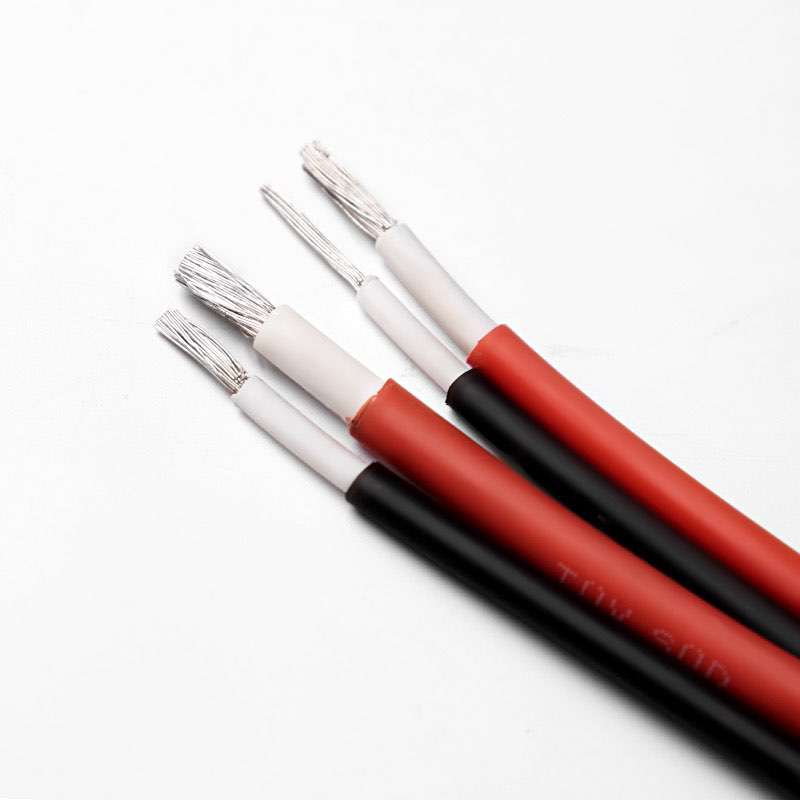

With the development and utilization of new energy, photovoltaic power generation has become more and more popular as a green and clean renewable energy. During the large-scale construction of photovoltaic power stations, the safe operation and use of photovoltaic power stations. Life design is particularly important. In order to ensure the long-term efficient and safe operation of photovoltaic power stations, many countries and regions require that the designed photovoltaic power stations have an operating life of more than 25. As for the photovoltaic cables and other photovoltaic power generation system components that are used as the power transmission medium of the photovoltaic power generation system, the designed service life should also not be less than 25 years. As one of the solar cable manufacturers with more than 20 years of production experience, tell you about the production of solar cable and how buyers should choose suppliers.

The aging of photovoltaic cables is mainly judged by the insulation and sheath. Since most of the insulation and sheath materials used in photovoltaic cables are low-smoke, halogen-free and flame-retardant cross-linked polyolefins, the time for such materials to be put into use is relatively short, and their lifespan It cannot be verified by actual use.

When solar cable manufacturers produce photovoltaic cables, they should use materials that meet the requirements of insulation and sheath standards to meet the needs of producing qualified cable products. For the commonly used XLPE, XLPO, or PVC materials in the production of insulation and sheath of photovoltaic cables, Each country and industry standard has its own standards. At present, Solar cable manufacturers generally publish these material standards by authoritative organizations. The procurement of insulation and sheath materials that meet the material standards can meet the requirements of the cable product standards. Therefore, the purchase contract is basically based on These material standards serve as the basis for quality acceptance.

Solar cable manufacturers use the same insulating sheath material and the same processing technology, and there will be no significant difference in quality. XLPE is heated, in the silanol condensation catalyst, under the action of the chemical agent, it will be hydrolyzed in contact with water to form a network of cross-linked oxane chains. Therefore, the cross-linking method is to realize the cross-linking of the extruded insulation through warm water or steam cooking. The main process parameters of this process are the cooking temperature and time. The cross-linking process documents of each plant are basically the same.The temperature is controlled at 90°C to 95°C uniformly. The crosslinking time is about 6 hours. In fact, cables of different specifications have different insulation thicknesses. As the thickness increases, the time exists for the inner and outer layers of the insulation to reach the process temperature and the contact water molecules to complete the hydrolysis and form a network structure.A certain difference; even for cores with the same insulation thickness, as the number of layers increases, the surface cores and intermediate cores wound on the cable reel reach the process temperature and contact water molecules to complete the hydrolysis and form a network structure. There are also certain differences in time. In addition, considering the different supply, the cross-linking materials produced by manufacturers are different in terms of formula, base materials, catalysts, antioxidants, etc., and their products also have different process characteristics and require different process parameters.

Solar cable manufacturers should obtain a product inspection certificate from TUV. The quality of insulation and sheathing materials is not easy to control. The inspection of insulation and sheathing materials for wires and cables requires special sample preparation equipment and some special inspection equipment for various complicated reasons. When choosing to purchase Solar cable, you should try to choose a factory that conforms to the ISO production system, and the product has a TUV certificate.

Welcome to contact us for more inquiries about wires and cables, as well as the latest prices.