Author: Joey Wan

Author: Joey Wan  November 12,2021

November 12,2021

The flame-retardant cable maintains the electrical and physical and chemical properties of ordinary cables, and at the same time it is self- extinguishing, that is, it is not easy to burn. Or the burning time is very short (within 60 minutes), or the extended burning length is very short.

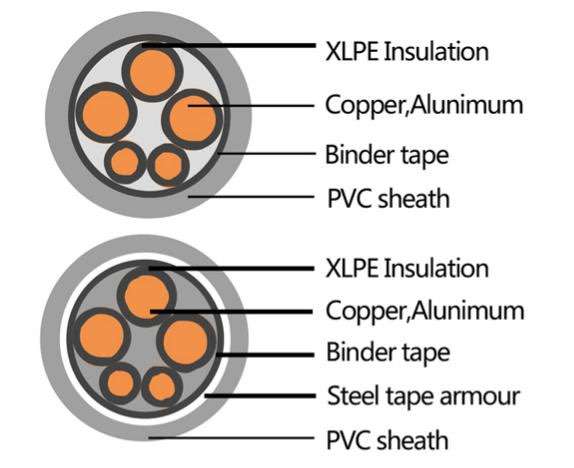

Because of its low cost, it blocks and delays the spread of flame along the cable, so that the fire will not expand. Therefore, it is a large number of cable varieties used in fire-resistant cables. The cable may be burnt out and unable to operate in the event of a fire, but it can prevent the spread of the fire and avoid greater losses.The structure of the flame-retardant cable is basically the same as that of the ordinary cable. The difference is that all or part of its insulating layer, sheath, outer sheath and auxiliary materials (tape and filling) are made of flame-retardant materials.

Fire rated cable and wires can continue to work (transmit current and signals) in the event of a fire, and whether they extend combustion or not is not included in the assessment. The flame-retardant cable stops working quickly when a fire occurs, and its function is to be inflammable and self-extinguishing without spreading; while the flame-retardant cable can maintain normal operation for 180 minutes in the flame burning of 750~800℃.

The fire rated cable has the power supply capacity for a certain period of time in the flame, and can maintain the normal operation of the line for a certain period of time when the flame is burning. In layman's terms, in case of fire, the cable will not burn at once, and the circuit is safer.

The structure of the fire rated cable is basically the same as that of the ordinary cable. The difference is that the conductor of the fire rated cable uses a copper conductor with good fire resistance (the melting point of copper is 1 083°C), and a fire-resistant layer is added between the conductor and the insulating layer. The refractory layer is wrapped by multiple layers of mica tape. Because the allowable working temperature of different mica tapes varies greatly, the key to the fire rated cable is the mica tape.

1. The difference between structure and material

The structure and materials of fire rated cables are different from those of flame-retardant cables. The basic structure of flame-retardant cable is:

(1) The insulating layer is made of flame-retardant materials

(2) The sheath and outer sheath are made of flame-retardant materials;

(3) The wrapping tape and filling are made of flame-retardant materials.

The fire rated cable usually adds a fire-resistant layer between the conductor and the insulating layer. Therefore, theoretically, a fire-resistant layer can be added to the structure of the flame-retardant cable to form a flame-retardant and fire rated cable. This is not necessary.

Because of the fire-resistant layer of the fire rated cable, a multi-layer mica tape is usually used to wrap the wire directly. It can withstand long-term combustion, even if the polymer at the place where the flame is applied is burned, it can ensure the normal operation of the line.

2. Different principles

The principle of fire rated cables is different from that of flame-retardant cables. The flame-retardant principle of halogen-containing cables is based on the flame-retardant effect of halogen, and the flame-retardant principle of halogen-free cables is to extinguish the fire by reducing the temperature of the precipitated water. Fire rated cables rely on the fire-resistant and heat-resistant characteristics of the mica material in the refractory layer to ensure the cable It also works fine during a fire.

Fire rated cables can maintain normal power supply for a period of time when a fire occurs, but flame-retardant cables do not have this feature. This characteristic determines that fire rated cables play an important role in modern cities and industrial buildings.

In general, fire rated cables can replace flame-retardant cables, but flame-retardant cables cannot replace fire rated cables.

Flame-retardant cables are suitable for places with high concentration of people and low air density that have high flame-retardant requirements.

Fire rated cables are suitable for all lines that need to be kept in normal operation during a fire, such as fire protection systems, emergency lighting systems, life-saving systems, alarms and important monitoring circuits in industrial and civil buildings.

4. Easy to install, because it allows a small minimum bending radius and light weight;

5. Not restricted by line drop;

6. Good thermal performance, high allowable working temperature and large transmission capacity;

7. The cable accessories are simple, all of which are dry structure;

8. Simple operation and maintenance, no oil leakage problem;

9. The price is lower;

10.High reliability and low failure rate;

11.The manufacturing process is few, the process is simple, and the economic benefit is remarkable.

Now we have known the XLPE cable, the flame retardant cable and fire rated cable so much respectively, so it will be suitable to try to do a conclusion about those 3 concepts we may feel confused in purchasing or procurement. Firstly XLPE cable refer to the cable with better insulation compared to the PVC cable, which belong to a wide definition in some way. Secondly the flame retardant cable points to the cable with insulation or jacket which is efficient to stop the fire to expand to other places once the fire appears. At last fire rated cable refers to while a circuit has the fire event, the fire rated cable still can maintain the working process normally within a specific times.

Have you got the meaning of XLPE cable, the flame retardant cable and fire rated cable now? Whatever you have got it or not, you can contact us JZD Wire&Cable to obtain more professional information about fire rated cable or other common used cable or wire in our daily life.

Manufacturer Tell You Why Cable THHN 12 AWG Is So Hot Sale Recently

Wholesaler Lets You Know What The Electrical Control Wire Is