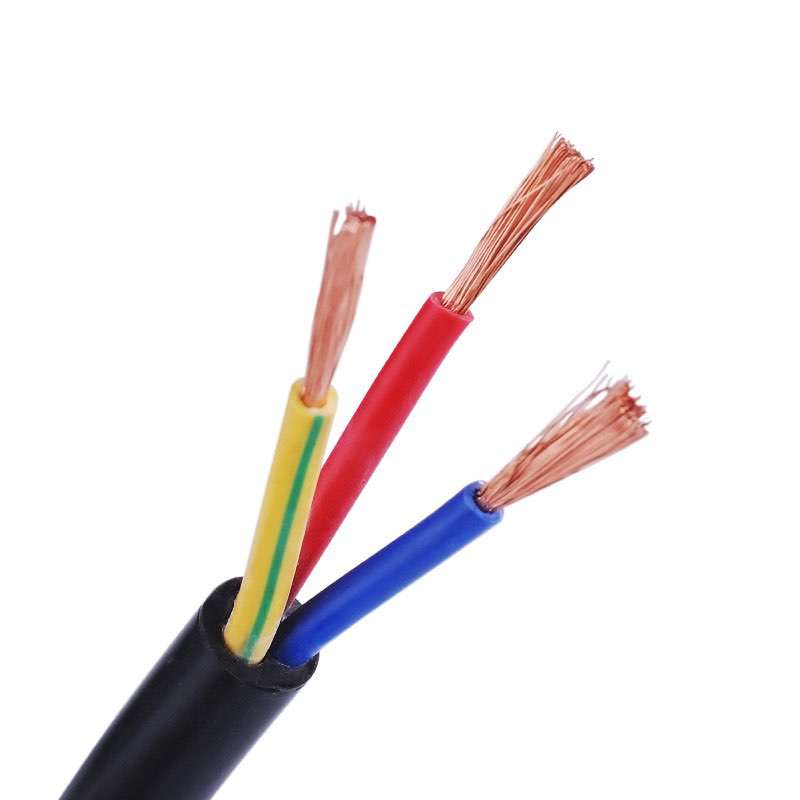

JZD cable provides high quality multi core flexible cable.

Product Decription3 core copper flexible cable is composed of 3 pure copper conductors and PVC sheath. Because the wire is flexible, it can be easily bent during installation.Usually used in electrical appliances, such as televisions, refrigerators, washing machines, air conditioners, and other household appliances, in the industrial field, it is mainly concentrated in electronic equipment such as power supply equipment and power equipment.

Product Description

| Type | H03VV-F, H05VV-F |

| Standard | GB/T5023, IEC60227, BS6500, VDE0281, JB/T8734 |

| Nominal Voltage | 300/300V, 300/500V |

| No. of Cores | 2~7 cores |

| Conductor | class 5 fine annealed copper wires |

| Insulation Material | PVC |

| Colour | requirement |

| Jacket | PVC |

|

|

|

|

|||

| Flame retardant and environmental protection, using industrial PVC insulation materials, with good flexibility, bending resistance, corrosion resistance, waterproof, flame retardant detection. | Multi-ply Copper Wire, high purity copper wire, accordance with the national standards, production to ensure cable durability and reliability. | Low eccentricity, the extrusion process is adopted to ensure the core-skewness of the wire, ensure the safety of electricity and effectively prevent a current break down. |

|||

|

|

|

||||

| Label, the line body print clear, convenient to use. | Strict Quality,24 processes layer upon layer inspection strict control, only to make the best cable. | ||||

Parameter

| Voltage Level (V) |

Nominal section (mm²) |

Toplimit of overall diameter (mm) |

Maximum DC resistance (20℃) |

Minimum insulation resistance (70℃) |

Recommended value of carrying capacity (A) |

Reference weight (KG,KM) |

| 300/300 | 2x0.5 | 5.9 | 3.9 | 0.012 | 10 | 37 |

| 2x0.75 | 6.3 | 26.0 | 0.01 | 13 | 47 | |

| 3x0.5 | 6.3 | 39.0 | 0.012 | 8 | 44 | |

| 3x0.75 | 6.7 | 26.0 | 0.01 | 10 | 58 | |

| 2x0.75 | 7.2 | 26.0 | 0.011 | 13 | 58 | |

| 300/500 | 2x1.0 | 7.5 | 19.5 | 0.01 | 16 | 66 |

| 2x1.5 | 8.6 | 13.30 | 0.01 | 20 | 89 | |

| 2x2.5 | 10.6 | 7.98 | 0.009 | 27 | 137 | |

| 2x4 | 12.4 | 4.95 | 0.007 | 38 | 205 | |

| 2x6 | 14.5 | 3.30 | 0.006 | 50 | 280 | |

| 3x0.75 | 7.6 | 26.00 | 0.011 | 9 | 70 | |

| 3x1.0 | 8.0 | 19.50 | 0.01 | 11 | 80 | |

| 3x1.5 | 9.4 | 13.300 | 0.01 | 12 | 112 | |

| 3x2.5 | 11.4 | 7.980 | 0.009 | 21 | 172 | |

| 3x4 | 13.5 | 4.950 | 0.007 | 27 | 255 | |

| 3x6 | 14.0 | 3.30 | 0.006 | 34 | 340 | |

| 4x0.75 | 8.3 | 26.0 | 0.011 | 10 | 84 | |

| 4x1.0 | 9.0 | 19.50 | 0.01 | 12 | 101 | |

| 4x1.5 | 10.5 | 13.30 | 0.01 | 13 | 141 | |

| 4x2.5 | 12.5 | 7.98 | 0.009 | 21 | 210 | |

| 4x4 | 14.6 | 4.95 | 0.007 | 27 | 310 | |

| 4x6 | 16.0 | 3.30 | 0.006 | 35 | 425 | |

| 5x0.75 | 9.3 | 26.00 | 0.011 | 10 | 103 | |

| 5x1.0 | 9.8 | 19.50 | 0.01 | 12 | 119 | |

| 5x1.5 | 11.6 | 13.30 | 0.01 | 13 | 172 | |

| 5x2.5 | 13.9 | 7.98 | 0.009 | 22 | 257 | |

| 5x4 | 16.5 | 4.95 | 0.007 | 27 | 386 | |

| 5x6 | 17.3 | 3.30 | 0.006 | 35 | 518 |

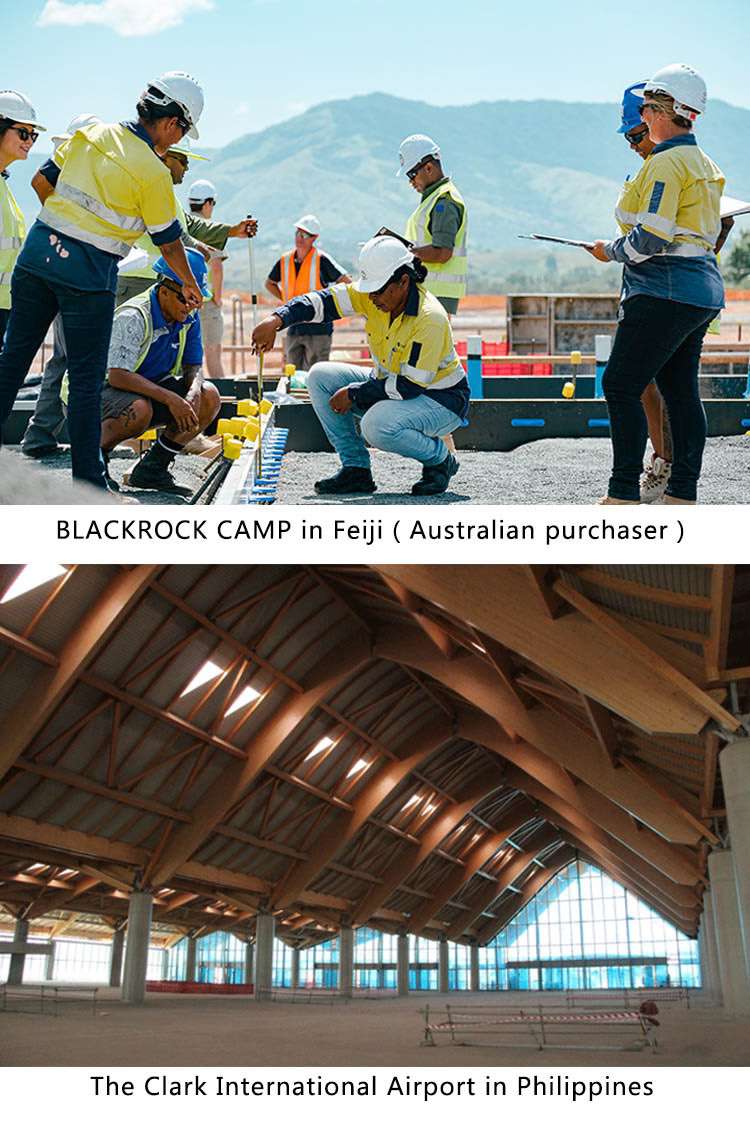

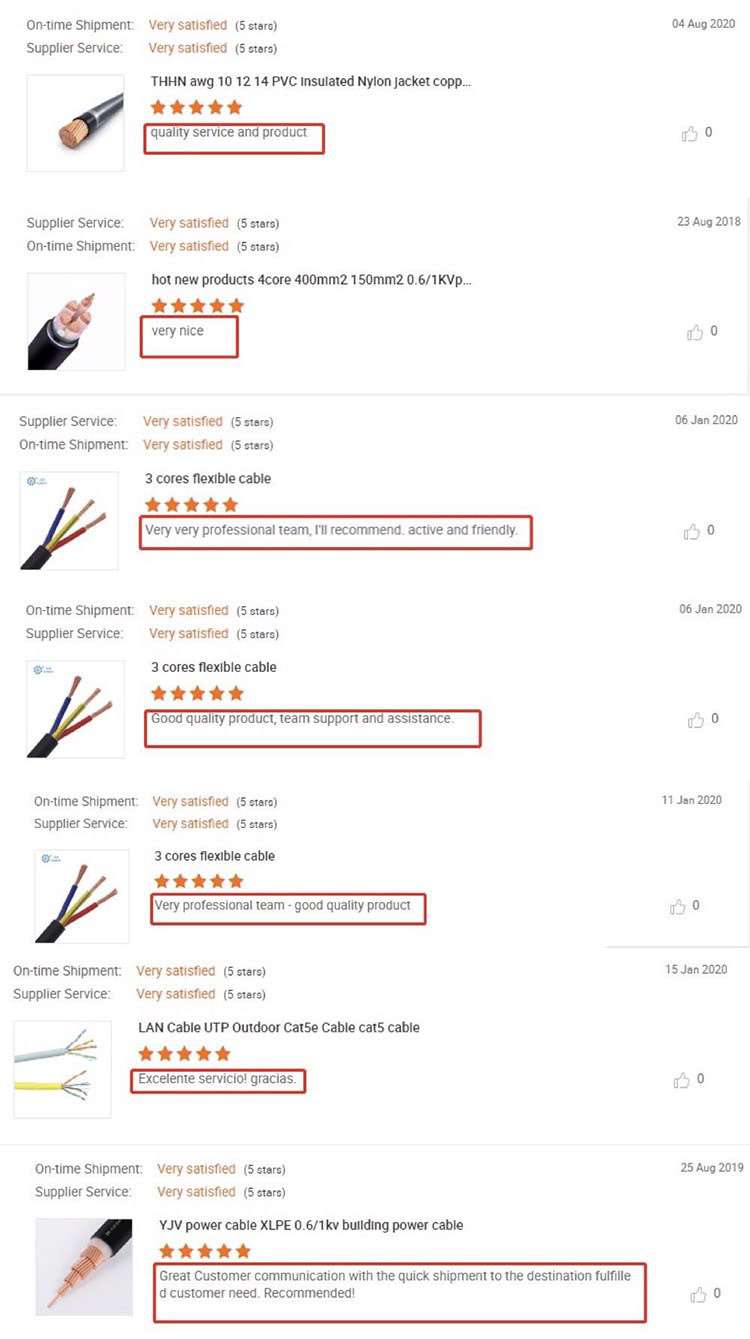

Case and Feedback