JZD cable provide single core solar cable, dual core solar cable, MC4 cable

Product Decription

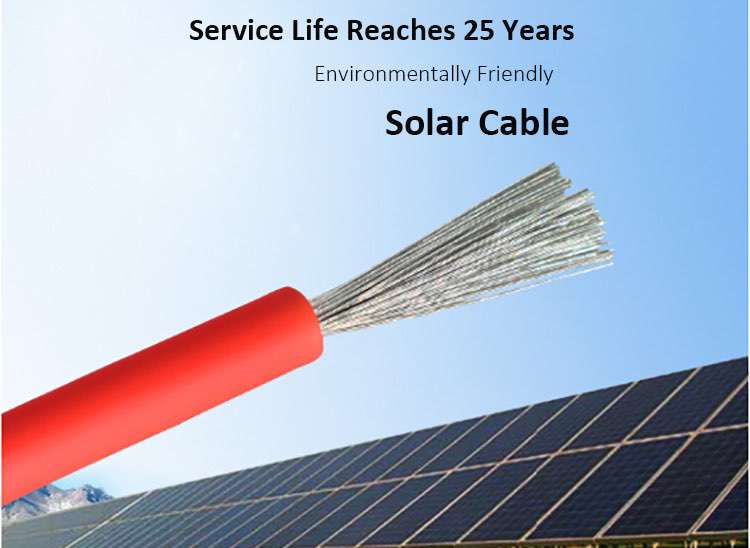

Solar cables are mainly used in harsh climate, high temperature resistance, cold resistance oil resistance,

acid and alkali resistance, UV resistance, flame retardant, environmental protection, service life of more

than 25 year.

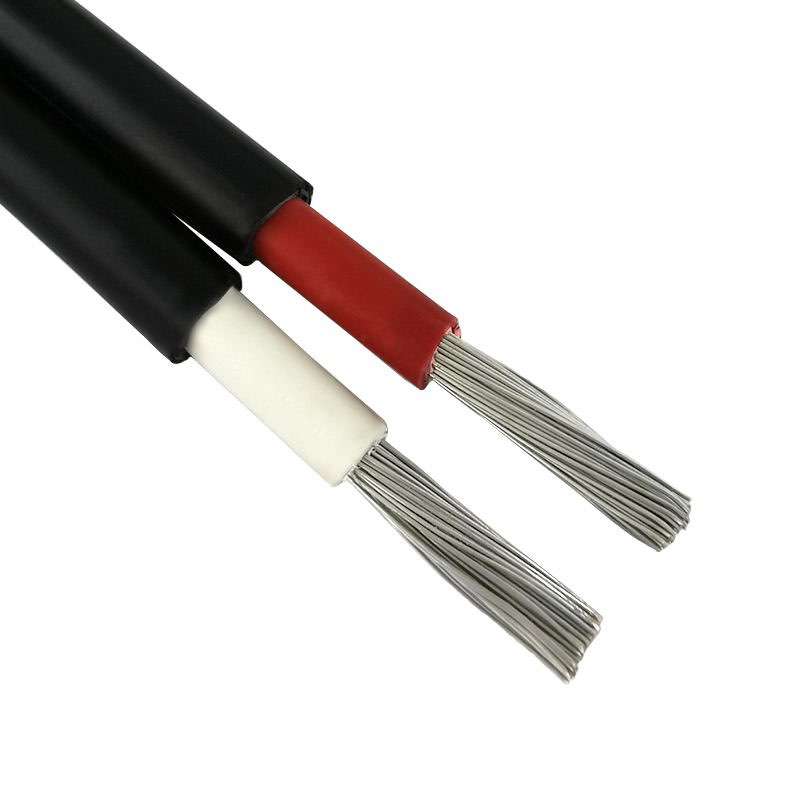

| Product | Double Core Solar Cable |

| Type | PV1-F |

| Voltage | 0.6/1KV |

| Conductor | Finely stranded tinned copper |

| No. of cores | Single core |

| Insulation | > 0.5MM Thick, LSZH / XLPE |

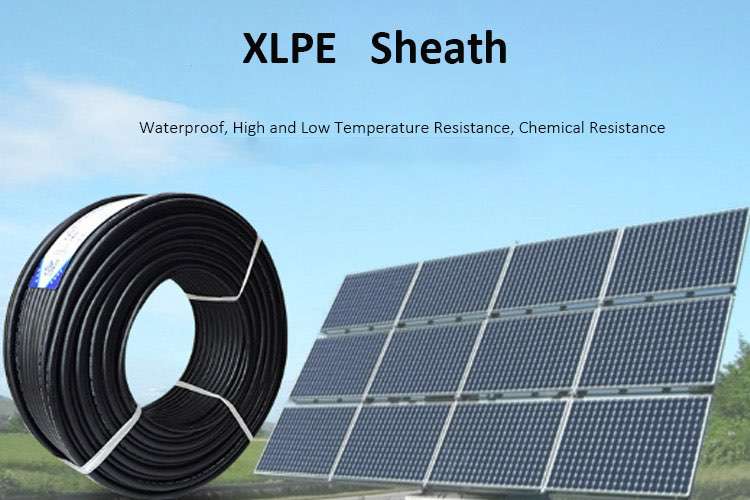

| Sheath | > 0.5MM Thick,XLPE |

| Ambient Temperature | - 40 ℃ ~ + 90 ℃ |

| The Highest Temperature of Conductor | 120 ℃ (allow 5 s in short circuit temperature 200 ℃) |

| Limited Voltage | AC0.6/1kv dc1.8kv |

| Standard | IEC60228 |

Feature

1. LSZH Sheath (Low smoke without halogen), good cold, ultraviolet, ozone - resistant and weather - resistant.

2. Flame retardant, cutting resistance, and penetration resistance.

Cable protection level Ⅱ level.

3. With 150 ℃ photovoltaic cable radiation as insulation materials.

4. It conforms to ROHS, and the insulation resistance is small after immersion.

Electrical

1. The dc resistance: the finished cable at 20 ℃ conductive wire core dc resistance is not greater than 5.09 Ω/km

2. The insulation resistance: the finished insulation resistance of cable at 20 ℃ should not less than 1014 Ω. Cm finished cable insulation resistance at 90 ℃ is not less than 1011 Ω. Cm

3. The sheath surface resistance: resistance of the finished cable sheath surface should be not less than 109 Ω.

|

TYPE |

Cross section |

Wire struct |

Conductor diameter |

Outer diameter |

Conductor resistance |

Rated voltage |

Rated current |

|

mm2 |

No.OD(mm) |

mm |

mm |

Ω/Km |

V AC/DC |

A |

|

|

1x2.5mm² |

2.5 |

48x0.25 |

2.0 |

5.2 |

8.06 |

1000/1800 |

30 |

|

1x4.0mm² |

4.0 |

56x0.30 |

2.6 |

6.4 |

4.97 |

1000/1800 |

50 |

|

1x6.0mm² |

6.0 |

81x0.30 |

3.3 |

7.2 |

3.52 |

1000/1800 |

70 |

|

1x10mm² |

10 |

74x0.40 |

4.4 |

8.3 |

2.12 |

1000/1800 |

90 |

|

2x2.5mm² |

2.5 |

48x0.25 |

2.0 |

6.2x9.9 |

8.06 |

1000/1800 |

30 |

|

2x4.0mm² |

4.0 |

56x0.30 |

2.6 |

6.9x11.30 |

4.79 |

1000/1800 |

50 |

|

2x6.0mm² |

6.0 |

81x0.30 |

3.3 |

7.1x14.50 |

3.52 |

1000/1800 |

70 |

Application