Author: Joey Wan

Author: Joey Wan  April 21,2022

April 21,2022

Many equipments that needs to be powered needs a wire. Since wires and cables carry important safety issues, strict inspection of the quality of wire and cable products can ensure normal and safe operation in all aspects. So what aspects should you pay attention to when purchasing wires?

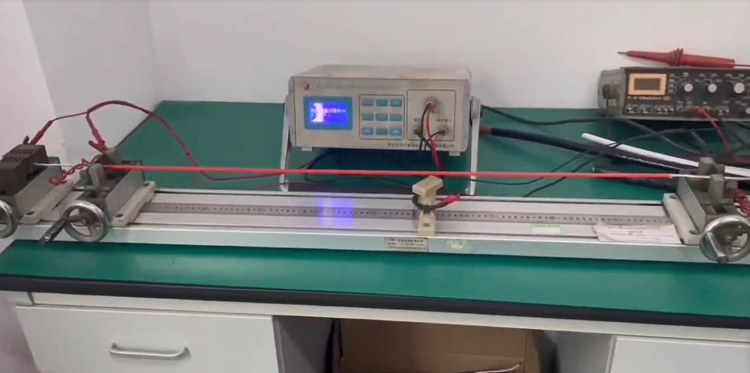

1. DC resistance inspection of wire and cable

The DC resistance inspection of wire and cable is one of the key items of wire and cable inspection-related experiments on its DC resistance factor can evaluate and calculate the quality of the wire core and the size of the wire diameter. Whether the electrical conductivity of the cable meets the standards for high-speed trains. Secondly, the size of the current resistance is also affected by the cross-sectional area of the wire and cable conductors, so it must be an important quality inspection content. Generally speaking, the maximum value of resistance occurs when the conductor is 20°C, so 20°C becomes an important limit value for evaluating the resistance value.

The most accurate detection will be when the resistance is converted to this value. Generally, we can use two methods to test the DC resistance of wires and cables, one is the current method, the other is the bridge method, both of which are good methods for testing, but the quality inspection personnel must choose the appropriate inspection according to the actual situation. method, so as to avoid measurement errors and keep the final detection value as accurate as possible.

numerical value.

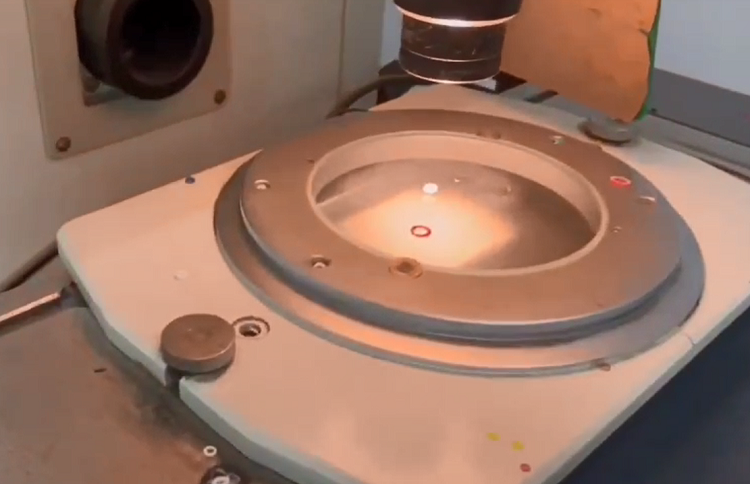

2. Insulation resistance inspection of wire and cable

The inspection of insulation resistance can ensure that the safety hazard is minimized and the wire and cable are in the best working condition, thereby preventing the damage of personnel and property, and better protecting the safety of the direct user of the wire and cable. There are obvious differences between the measurement of insulation resistance and the measurement of DC resistance. When measuring the exact value of insulation resistance, an accurate judgment must be made according to the size of the effective length. This measurement principle comes from the proportional relationship between the length of the wire and cable and the insulation resistance. . Generally speaking, the high resistance meter method, also known as the voltage and current method, is the best measurement method for testing the insulation resistance of wires and cables. properties and insulation properties of the wire cores, etc. The quality inspection of the insulation resistance of the wire and cable can effectively draw the insulation of the wire and cable.

The testing of cables is generally based on the above two standards. JZD cable manufacturer provides wires and cables with multiple certifications.