In the world of industrial automation and control, reliable and certified cables are essential for seamless data communication and electrical signal transmission. One such widely used cable is UL2464, a multi-conductor shielded cable that meets Underwriters Laboratories (UL) standards. Known for its durability, flexibility, and compliance with safety regulations, UL2464 is commonly found in control systems, computer interfaces, and industrial equipment wiring.

1. What is UL2464 Cable?

UL2464 is a type of multi-conductor shielded cable listed under UL758 Appliance Wiring Material (AWM) standards. It is primarily designed for internal wiring of electronic equipment and data communication systems.

Key Technical Features:

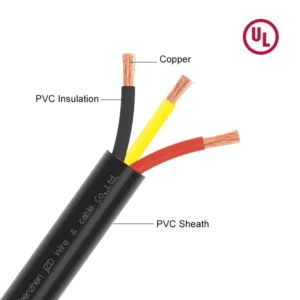

Conductor Material: Stranded or solid bare copper

Insulation: PVC (Polyvinyl Chloride)

Shielding: Aluminum Mylar foil (often with drain wire)

Outer Jacket: Flexible PVC

Voltage Rating: 300V

Temperature Rating: -20°C to 80°C (varies with jacket)

Compliance & Certifications:

UL2464 is recognized by UL (Underwriters Laboratories) and is commonly marked as AWM Style 2464.

It is suitable for low-voltage data transmission and complies with flame retardant requirements outlined in UL1581 VW-1.

This cable type is not intended for high-power transmission but excels in signal and data control, especially in environments requiring shielding against electromagnetic interference (EMI).

2. Key Applications of UL2464 Cable

UL2464 cable is widely recognized for its versatility across numerous industrial and commercial settings. Its combination of multi-conductor construction, EMI shielding, and UL compliance makes it the go-to choice for transmitting control signals, low-voltage power, and data in complex environments.

2.1 Industrial Automation Systems

UL2464 is extensively used in programmable logic controllers (PLCs), motor control centers (MCCs), and factory automation devices. These environments require robust cabling solutions that can transmit control signals reliably while resisting electrical noise. UL2464’s shielded construction helps maintain signal integrity in high-interference areas.

Examples:

PLC-to-sensor or actuator connections

Internal wiring of robotic arms or conveyor systems

Data communication between industrial devices

2.2 Control Panels & Instrumentation Wiring

In electrical control cabinets, where multiple signals and power lines run side by side, UL2464 serves as a reliable control cable. It ensures stable transmission between panel components, such as switches, meters, relays, and terminal blocks.

Typical uses:

Wiring in distributed control systems (DCS)

Analog/digital signal transfer for instrumentation

Low-voltage relay or contactor control lines

2.3 Data Acquisition and Communication Interfaces

UL2464 is a preferred cable type for RS-232, RS-422, and RS-485 serial communication protocols, which are commonly used in industrial networks and computer-controlled machinery. The shielding layer prevents data loss due to external noise.

Key scenarios:

Connecting industrial PCs to sensors or controllers

Wiring SCADA systems

Serial communication over moderate distances

2.4 Security & Surveillance Systems

In commercial and industrial buildings, UL2464 is used to connect CCTV cameras, access control panels, and alarm systems. It is well-suited for transmitting video and control signals thanks to its low-capacitance and shielding properties.

2.5 Non-Critical Medical Equipment

Although not typically used in life-support equipment, UL2464 is sometimes found in non-critical medical devices such as patient monitoring systems, where safe and consistent signal delivery is necessary.

2.6 Lab & Test Equipment Cabling

Laboratory instruments often rely on precise data logging and communication. UL2464 offers the necessary signal clarity and flexibility to serve in laboratory environments or portable test systems.

2.7 Summary of Key Advantages in Applications:

| Application Field | Purpose | Key Benefit |

| Automation | Signal/control wiring | EMI protection, flexibility |

| Control Panels | Internal cabinet wiring | Easy installation, reliable |

| Data Communication | Serial interface cabling | Signal integrity |

| Security Systems | CCTV and alarm connections | Noise shielding |

| Medical/Lab Equipment | Device-to-device communication | Low capacitance, compliance |

3. Advantages and Performance Features of UL2464 Cable

UL2464 is more than just a standard multi-conductor cable — it is engineered to deliver high reliability, flexibility, and compliance in demanding industrial environments. Its design ensures safe, interference-resistant operation, especially in systems where data integrity and control precision are critical.

3.1 Excellent Flexibility and Easy Installation

Thanks to its stranded copper conductors and soft PVC insulation, UL2464 is highly flexible. This makes it easy to route through tight spaces, cable trays, or crowded control panels — especially useful in industrial automation or instrumentation systems.

Reduces cable strain and breakage during frequent movement or maintenance

Ideal for dynamic wiring layouts and custom assembly workstations

3.2 Effective Electromagnetic Interference (EMI) Shielding

One of the biggest performance strengths of UL2464 is its shielded structure, typically aluminum Mylar foil wrapped around conductors with an optional drain wire. This helps prevent signal loss due to external interference and enhances communication reliability, especially in high-noise electrical environments.

Suitable for RS-232/RS-485 data transfer

Protects against crosstalk and electrical noise from nearby machinery

3.3 lame Retardant and Safe

UL2464 cables meet VW-1 vertical flame test under UL1581, providing a safety guarantee in case of electrical failure or overheating. The PVC jacket not only offers physical protection but also adds flame resistance to meet compliance in both North American and global markets.

Broad Temperature Range and Durability

UL2464 typically operates within a temperature range of -20°C to +80°C, making it suitable for most indoor industrial environments. The robust outer jacket resists abrasion, oil, and chemical exposure, ensuring long service life under daily mechanical stress.

3.4. High Compliance & Traceability

Every UL2464 cable comes with clear UL marking and style number, ensuring traceability and peace of mind for engineers and purchasers dealing with regulatory inspections or client audits.

Enables easy sourcing for export to the U.S. and Canada

Matches international safety expectations for OEMs and equipment suppliers

3.5. Cost-Effective Compared to Custom Cabling

Compared with more expensive or custom-designed cables, UL2464 offers a cost-effective solution for low-voltage signal transmission and control tasks. It provides just the right balance of performance, safety, and price for most industrial OEM and retrofit applications.

4. Comparison Between UL2464 and Similar Cable Types

While UL2464 is widely used in control and signal applications, it’s essential to understand how it differs from other UL-certified or industrial cable types. Choosing the right cable depends on application requirements, shielding needs, flexibility, and compliance levels.

UL2464 vs UL2517

UL2517 is another PVC-jacketed multi-core cable used for internal wiring. However:

| Feature | UL2464 | UL2517 |

| Voltage Rating | 300V | 300V |

| Shielding | Often shielded (foil + drain wire) | Typically unshielded or optional |

| Flexibility | More flexible (stranded) | Slightly stiffer |

| Use Case | Control signals, data communication | Internal appliance wiring |

Takeaway: UL2464 offers better EMI protection and is more suitable for external data and control signal transmission.

UL2464 vs UL20276

UL20276 is a communication cable often used in audio/video and computer systems.

| Feature | UL2464 | UL20276 |

| Application | Industrial automation, control | Multimedia, computer peripheral wiring |

| Jacket Type | PVC | PVC or thermoplastic |

| Shielding | Foil shield | May include braid + foil |

Takeaway: UL20276 may offer better multi-layer shielding, but UL2464 is better suited for industrial environments with control wiring needs.

UL2464 vs UL2919 (Video Coax Cable)

UL2919 is designed for video signal transmission, often as coaxial or hybrid cable.

| Feature | UL2464 | UL2919 |

| Signal Type | Digital/analog control and data | Video and multimedia |

| Construction | Multi-conductor + shield | Coaxial (center core + braid/foil) |

| Use Case | Automation, control panels | AV systems, monitors, projectors |

Takeaway: UL2919 provides higher bandwidth for video, while UL2464 is optimized for multi-core data/control signals.

UL2464 vs Non-UL Industrial Control Cable

Non-UL cables may offer similar constructions but lack certified traceability and safety standards, which can pose risks in export and regulated industries.

| Feature | UL2464 | Non-UL Control Cable |

| Certification | UL Listed (Style 2464) | No UL certification |

| Use in North America | Fully compliant | May not pass inspection |

| Flame Rating | VW-1 Flame Test | May not meet UL1581 |

Takeaway: For companies exporting to the U.S. or working under strict safety protocols, UL2464 ensures regulatory compliance and reliability.

In summary, UL2464 strikes a unique balance of:

Signal shielding

Cost-efficiency

UL traceability

Application flexibility

making it the preferred cable in many B2B and OEM environments.

5. Selection Guide and Practical Considerations for UL2464

Choosing the right UL2464 cable for your project requires more than just confirming voltage and temperature ratings. You must assess the application environment, circuit requirements, and compliance demands to ensure safety and long-term performance.

Here’s a practical guide to help you evaluate your options:

5.1 Determine Conductor Size and Core Count

UL2464 cables are available in multiple AWG sizes (commonly 18AWG to 28AWG) and configurations, from 2-core to 20+ conductors.

Signal strength and distance will impact the required conductor size

Choose fewer cores for simple sensor/relay applications, and more for complex control wiring

Tip: For RS-485 or data transmission, 24AWG–26AWG is typical. For power and control lines, opt for thicker sizes like 18AWG.

5.2 Consider Shielding Type and Noise Conditions

Although UL2464 often includes foil shielding, some versions come unshielded for cost-sensitive projects.

In noisy environments (with motors, inverters, or fluorescent lighting), shielded versions are essential

In low-noise or isolated systems, unshielded options may be sufficient

Tip: Always verify whether your application demands protection from EMI or RFI (radio frequency interference).

5.3 Evaluate Environmental Factors

UL2464 is rated for indoor use, but environmental exposure still matters:

Is the cable exposed to oil, chemicals, or mechanical wear? Use oil-resistant jackets.

Will it operate near heat sources or cold storage? Check the temperature range.

Is the installation area subject to frequent movement? Choose a flex-rated variant.

Note: UL2464 is not intended for outdoor or direct burial use unless otherwise specified by the manufacturer.

5.4 Check for Global Compliance (if exporting)

If you’re building equipment for North American markets, UL2464 compliance is often mandatory.

For global applications, consider:

RoHS (Restriction of Hazardous Substances)

REACH (EU chemical safety regulations)

CE (for European exports)

Make sure your cable supplier provides documentation and third-party test reports for verification.

5.5 Select the Right Packaging and Length Options

For OEMs or cable harness assembly, spool length and cut-to-length customization may be needed

Some vendors offer pre-terminated UL2464 assemblies, which reduce installation labor

Tip: Always order 10-15% more length than estimated to allow for rework, routing slack, and unexpected rerouting during installation.

5.6 Common Pitfalls to Avoid

Using unshielded UL2464 in a high-EMI environment

Mismatching AWG size with load requirements

Assuming fire rating without checking UL VW-1 certification

Deploying in outdoor/exposed areas without additional protection

UL2464 cable stands out as a cost-effective, UL-compliant, and versatile solution for control and signal transmission in industrial environments. Its flexible construction, EMI shielding, and certified safety make it suitable for applications ranging from automation systems to surveillance, data communication, and instrumentation.

Whether you’re wiring control panels, connecting industrial PLCs, or building export-ready OEM devices, UL2464 provides the right balance of performance, durability, and regulatory compliance.

If your project requires stable, low-voltage signal control and North American compliance, UL2464 is a smart, proven choice.

6. FAQs

Q1: Can UL2464 be used outdoors?

A: UL2464 is not rated for direct outdoor use or burial. For outdoor environments, consider using it within protective conduits or choose cables specifically designed for UV/weather resistance.

Q2: Is UL2464 suitable for power transmission?

A: No. UL2464 is rated for 300V and is primarily intended for signal and control purposes. It is not suitable for high-current power applications.

Q3: What makes UL2464 different from regular control cables?

A: UL2464 is certified under UL758 standards, ensuring high safety, fire resistance (VW-1), and traceability — particularly important for export-oriented or regulated industries.

Q4: Is UL2464 cable RoHS compliant?

A: Most modern UL2464 cables are RoHS compliant, but you should confirm with your supplier and request documentation before purchase, especially for export projects.

Q5: Can I use UL2464 for RS-485 communication?

A: Yes. UL2464 is commonly used for RS-232, RS-422, and RS-485 interfaces, particularly the shielded versions that protect against EMI and maintain signal integrity.

Q6: Is UL2464 flame-retardant?

A: Yes. UL2464 typically complies with the VW-1 flame test standard defined under UL1581, making it suitable for use in enclosed industrial systems.