When it comes to electrical cables, two of the most widely used types are PVC cables and XLPE cables. While both serve the purpose of transmitting electrical power, they differ significantly in terms of material composition, performance, and applications. In this article, we will delve into the key differences between these two types of cables and explain why XLPE cables are often considered the superior choice for demanding electrical systems.

PVC cables, or polyvinyl chloride cables, are known for their affordability and versatility. They are commonly used in low-voltage applications, such as fixed installations in power plants with AC ratings between 450V and 750V. However, PVC has its limitations. For instance, it has a relatively low softening point of 176°F and begins to decompose at 266°F. When exposed to high temperatures, PVC cables can melt or catch fire, releasing toxic fumes that are harmful to humans and the environment.

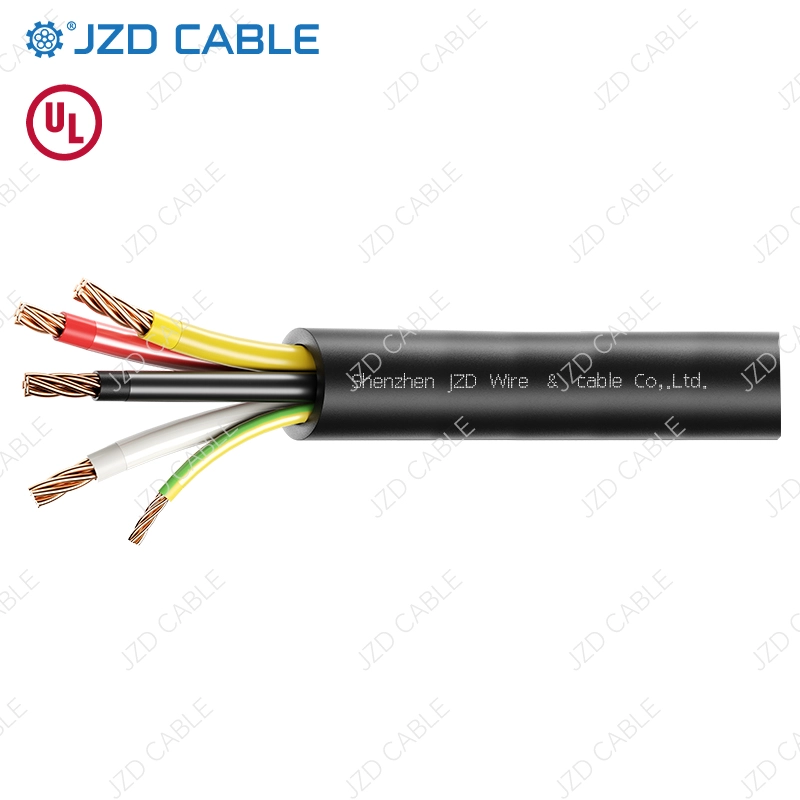

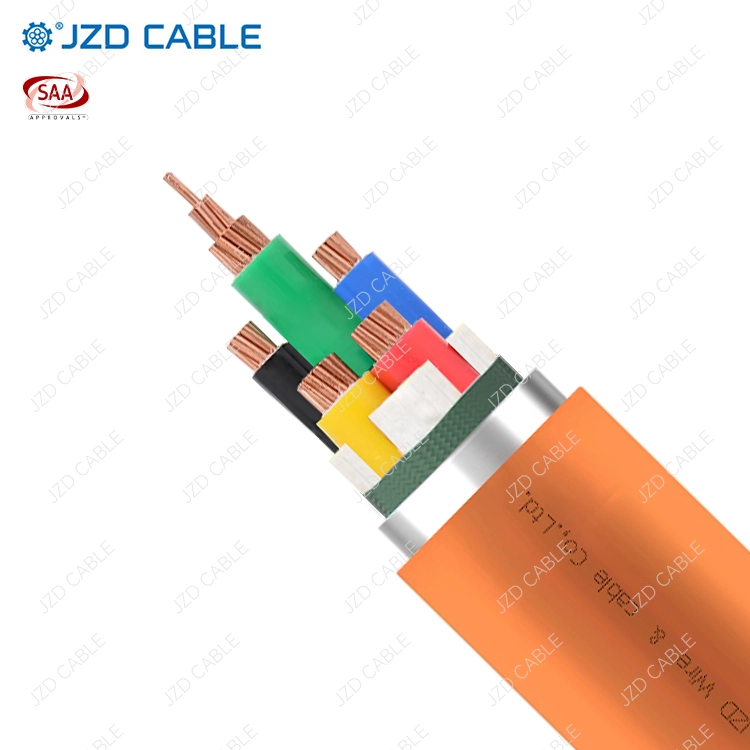

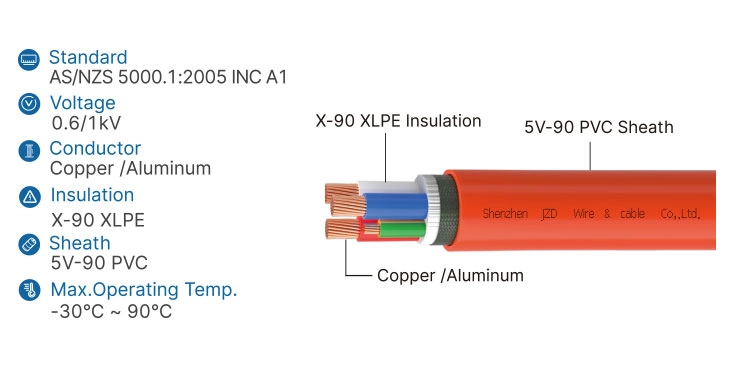

On the other hand, XLPE cables, which stand for cross-linked polyethylene cables, are engineered for enhanced performance and durability. XLPE is often regarded as an upgraded version of PVC insulation due to its superior properties. These cables are ideal for use in distribution networks, industrial equipment, and other high-capacity electrical applications. They are designed for fixed installations in AC power systems with rated voltages ranging from 6kV to 35kV.

One of the most notable advantages of XLPE cables is their exceptional heat resistance. Thanks to their cross-linked molecular structure, XLPE cables can withstand temperatures up to 572°F without decomposing or carbonizing. This makes them suitable for long-term use at temperatures as high as 194°F, with a lifespan of up to 40 years. Additionally, XLPE cables maintain excellent insulation properties, including high insulation resistance and low dielectric loss, which remain stable across a wide temperature range.

Mechanically, XLPE cables are also superior. The cross-linking process enhances their hardness, stiffness, abrasion resistance, and impact resistance, addressing common weaknesses found in PVC cables. Furthermore, XLPE cables exhibit strong resistance to chemicals, including acids and oils, making them suitable for harsh environments. When exposed to fire, XLPE cables primarily produce water and carbon dioxide, posing minimal environmental and safety risks compared to PVC cables.

While XLPE cables are generally more expensive than PVC cables, their long-term benefits far outweigh the initial cost. They offer greater reliability, efficiency, and safety, making them the preferred choice for critical applications.

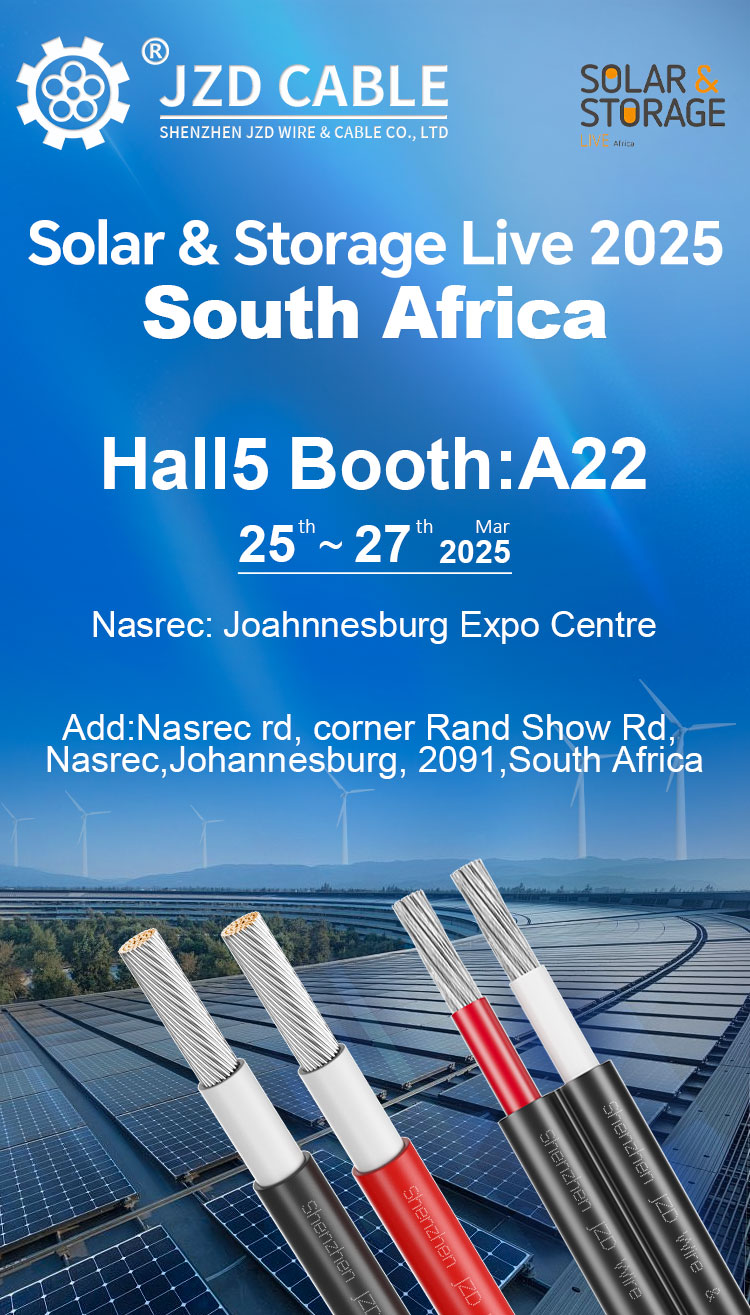

At JZD Cable, we specialize in manufacturing high-quality XLPE cables that meet the highest industry standards. Our products are designed to deliver unmatched performance, durability, and value. Whether you need cables for industrial, commercial, or residential use, JZD Cable is your trusted partner for all your electrical wiring needs.

For more information about our XLPE cables or to discuss your specific requirements, feel free to contact us. We are committed to providing cost-effective solutions without compromising on quality.