n the world of electrical wiring, not all cables are created equal. For applications requiring durability, flexibility, and resilience under extreme conditions, UL3529 certified silicone wire stands out as a top choice. At JZD Cable, we take pride in manufacturing high-performance silicone wires that meet the stringent requirements of modern industries. This blog provides a detailed overview of UL3529 silicone wire, its applications, and the key differences that set it apart from ordinary wire.

Introduction to UL3529 Silicone Wire

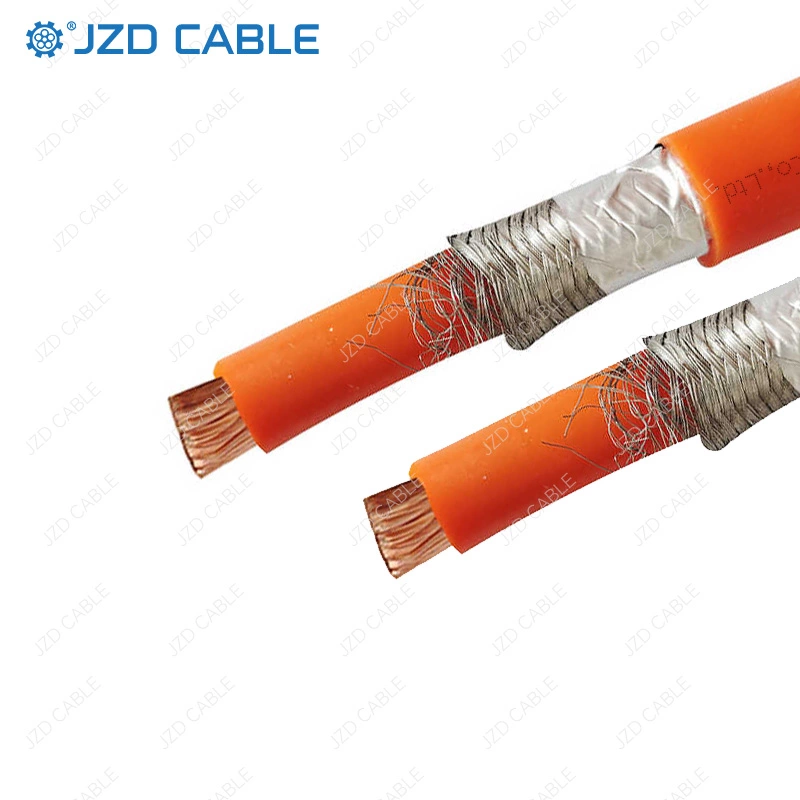

UL3529 silicone wire is expertly crafted using high-quality silicone insulation and finely stranded tinned copper conductors. This combination ensures exceptional thermal stability, electrical conductivity, and resistance to environmental challenges. Designed to perform reliably in both high and low-temperature settings, this wire is a versatile solution for numerous demanding applications.

One of the standout features of UL3529 silicone wire is its impressive temperature rating, which ranges from -60°C to +180°C. This means it can function effectively in freezing conditions as well as extremely hot environments without compromising safety or performance. Additionally, it boasts a rated voltage of 600V and can withstand test voltages of up to 2000V, making it suitable for high-power applications.

The wire is also certified to meet important international standards. It complies with the RoHS directive, ensuring it is free from hazardous substances, and carries the UL3529 certification, which attests to its safety and reliability. Furthermore, it passes rigorous flame resistance tests such as UL VW-1 and CSA Ft1, providing peace of mind in applications where fire safety is critical.

Other notable properties include excellent resistance to oil, water, chemicals, and abrasion. Its silicone insulation remains flexible even in cold conditions, simplifying installation and reducing the risk of damage during handling. These attributes make it an ideal choice for use in challenging environments where ordinary wires would quickly fail.

![]()

Applications of UL3529 Silicone Wire

Thanks to its robust design and versatile properties, UL3529 silicone wire is used across a wide range of industries. In household appliances, it is often found in high-temperature devices such as microwaves, ovens, and electric heaters, where it ensures safe and consistent performance. Its ability to resist heat and moisture also makes it suitable for use in lighting systems, especially high-intensity lamps and outdoor fixtures exposed to varying weather conditions.

In industrial settings, this wire is invaluable for machinery and equipment that operate under extreme stress. It is commonly used in manufacturing units, welding equipment, and power generation systems, where reliability is non-negotiable. The wire’s durability and resistance to abrasion and chemicals make it well-suited for these demanding applications.

The automotive and electronics industries also benefit greatly from UL3529 silicone wire. In vehicles, it is used in wiring harnesses that must endure engine heat and vibrations. In electronics, it provides dependable connections for devices that generate heat or are used in environments with fluctuating temperatures.

Overall, the adaptability and resilience of UL3529 silicone wire make it an excellent choice for any application requiring long-lasting performance under challenging conditions.

![]()

Differences Between Silicone Wire and Ordinary Wire

When comparing silicone wire to ordinary wire, several key differences become apparent. Ordinary wires, typically made with PVC or other thermoplastic materials, are designed for general-purpose use in moderate environments. They usually have a lower temperature tolerance, with many rated for temperatures up to only 105°C. Beyond this point, ordinary wires can soften, melt, or degrade, posing a risk of electrical failure or even fire.

In contrast, silicone wire is built to handle extreme temperatures. Its silicone rubber insulation is thermoset, meaning it does not melt when exposed to high heat. Instead, it maintains its structural integrity, ensuring continuous safety and performance. This makes silicone wire ideal for applications involving high temperatures or sudden thermal fluctuations.

Another important distinction lies in flexibility and durability. Silicone wire remains soft and pliable even in cold conditions, while ordinary wires can become stiff and brittle. This flexibility simplifies installation and reduces the risk of cracking or breaking during use. Additionally, silicone wire offers superior resistance to oils, chemicals, and moisture, which allows it to perform reliably in humid or corrosive environments where ordinary wires might deteriorate quickly.

From a safety perspective, silicone wire often exceeds industry standards. With certifications like UL3529 and the ability to pass flame resistance tests, it provides an added layer of protection in high-risk applications. Ordinary wires, while adequate for basic uses, lack these advanced safety features.

In summary, while ordinary wires are sufficient for everyday applications, silicone wire is the clear choice for demanding environments where temperature extremes, mechanical stress, or environmental factors are a concern.

![]()

Conclusion

UL3529 certified silicone wire represents a significant advancement in electrical wiring technology. Its ability to perform under extreme conditions, combined with its durability and safety features, makes it an indispensable component in many industries. At JZD Cable, we are committed to providing our customers with reliable, high-quality wiring solutions tailored to their specific needs.

If you would like to learn more about our products or discuss how UL3529 silicone wire can benefit your projects, please do not hesitate to contact us. JZD Cable always ready to assist you.