What is PV Cable?

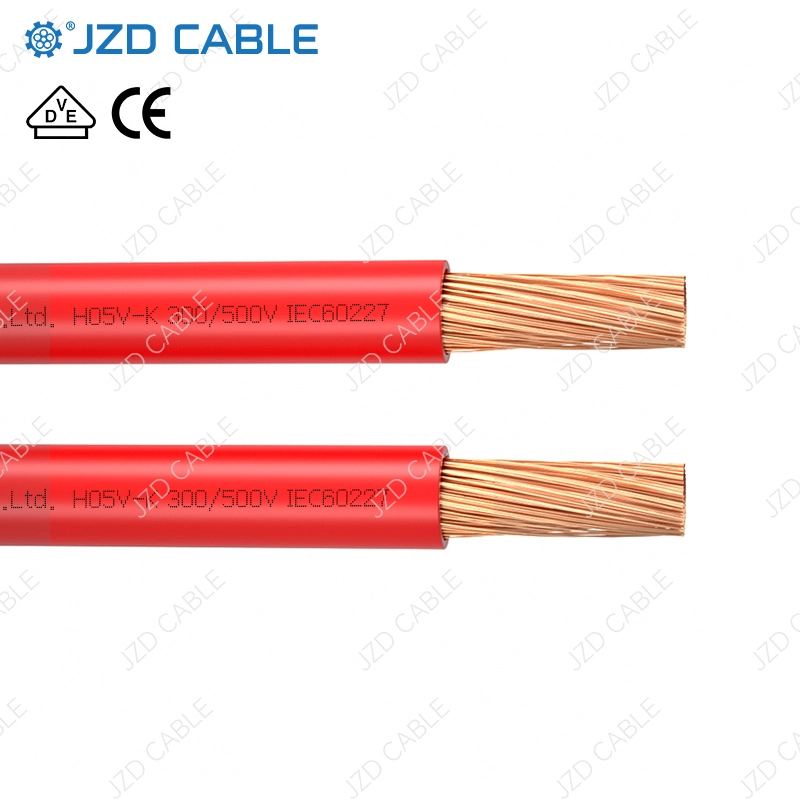

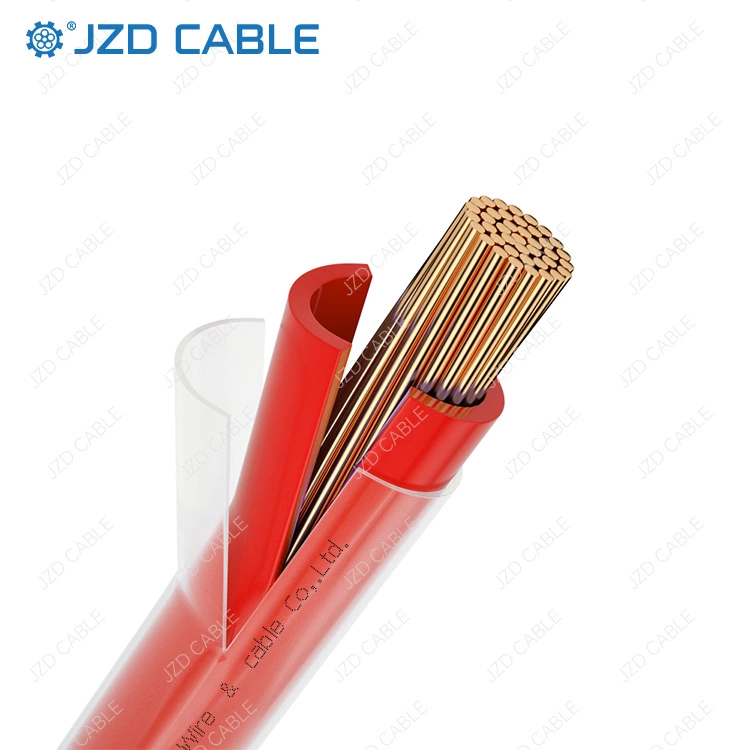

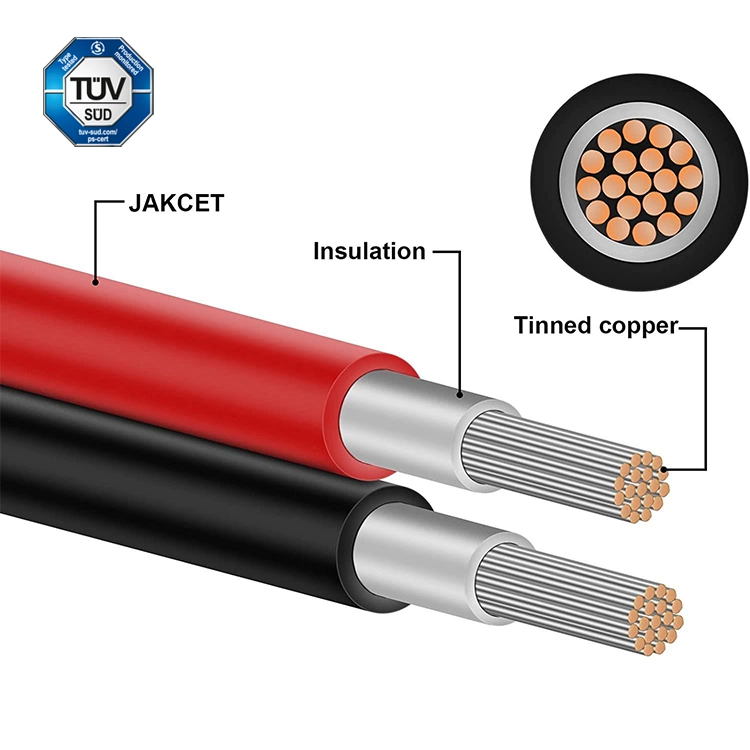

Key Features of PV Cables

-

Weather Resistance: Resistant to UV radiation, ozone, salt spray, and weak acid/alkali corrosion. Adaptable to extreme temperature changes. -

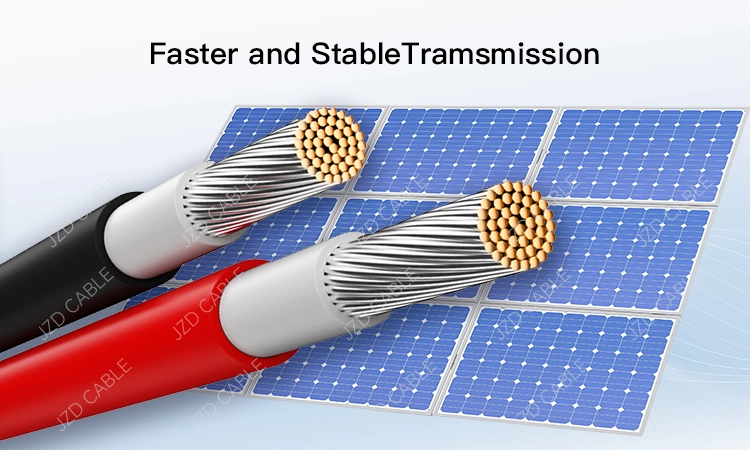

Electrical Performance: Low resistance and high current-carrying capacity minimize power transmission losses. DC-side voltage drop should be controlled within 2%. -

Safety and Environmental Friendliness: Made of low-smoke, halogen-free, flame-retardant materials to reduce toxic gas emissions during fires. Compliant with environmental standards. -

Mechanical Strength: Highly flexible, resistant to bending, stretching, and impact, suitable for complex wiring scenarios.

Typical Applications

-

Inter-Component Connections: Used to connect PV panels in series or parallel, ensuring efficient energy transmission within the array. -

Combiner Box to Inverter Connections: Transmit DC power to inverters, serving as the core transmission line in PV power stations. -

Distribution Box and Equipment Connections: Include DC distribution boxes to inverters and inverters to grid (AC side) connections.

Common Mistakes in PV Cable Selection

-

Incorrect Conductor Size or Voltage Rating: Cables must handle the load. Undersized cables can overheat, cause voltage drops, or exceed specifications, increasing costs unnecessarily. -

Improper Installation: Cables must be installed according to environmental conditions and specifications. Over-bending or compression can damage insulation, leading to short circuits. -

Ignoring Environmental Factors: Cables must suit the operating environment. Neglecting temperature, chemical exposure, or mechanical stress can cause premature aging or safety hazards. -

Using Low-Quality Cables: Cheap cables may save costs initially but lead to issues like wear, damage, short circuits, or failure. -

Overlooking Certifications: Ignoring UL, CE, or TUV certifications may result in non-compliance or safety risks.

How to Avoid These Pitfalls

-

Evaluate environmental conditions, mechanical demands, and electrical requirements. -

Verify certification compliance and ensure cables meet project-specific parameters. By applying these criteria, engineers can prevent performance mismatches and ensure reliable long-term operation.