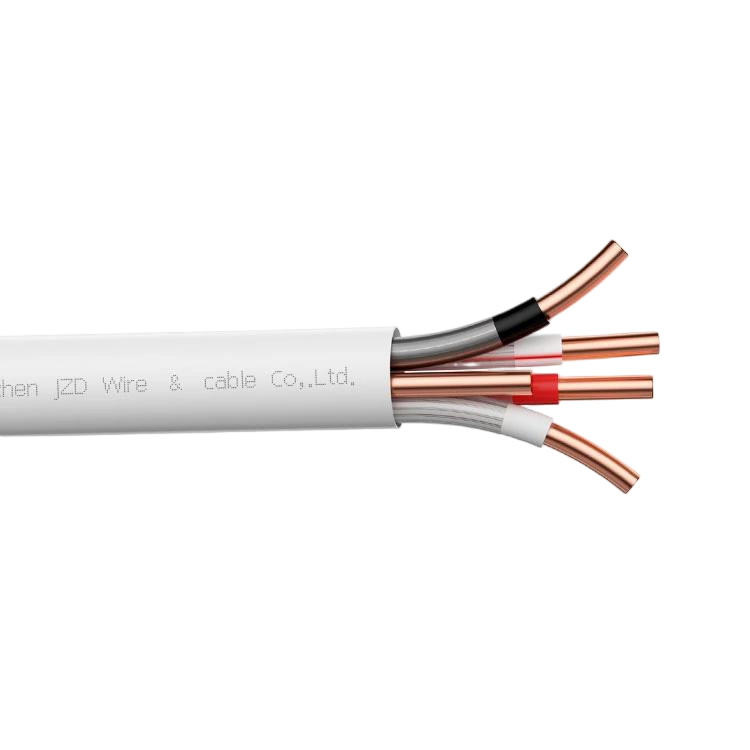

What Are Silicone Wires?

Functions of Silicone Wires

- Permanent connections under mechanical stress and high temperatures.

- Long service life and halogen-free nature, reducing maintenance costs.

- Consistent signal integrity in sensitive electronic or medical equipment.

![]()

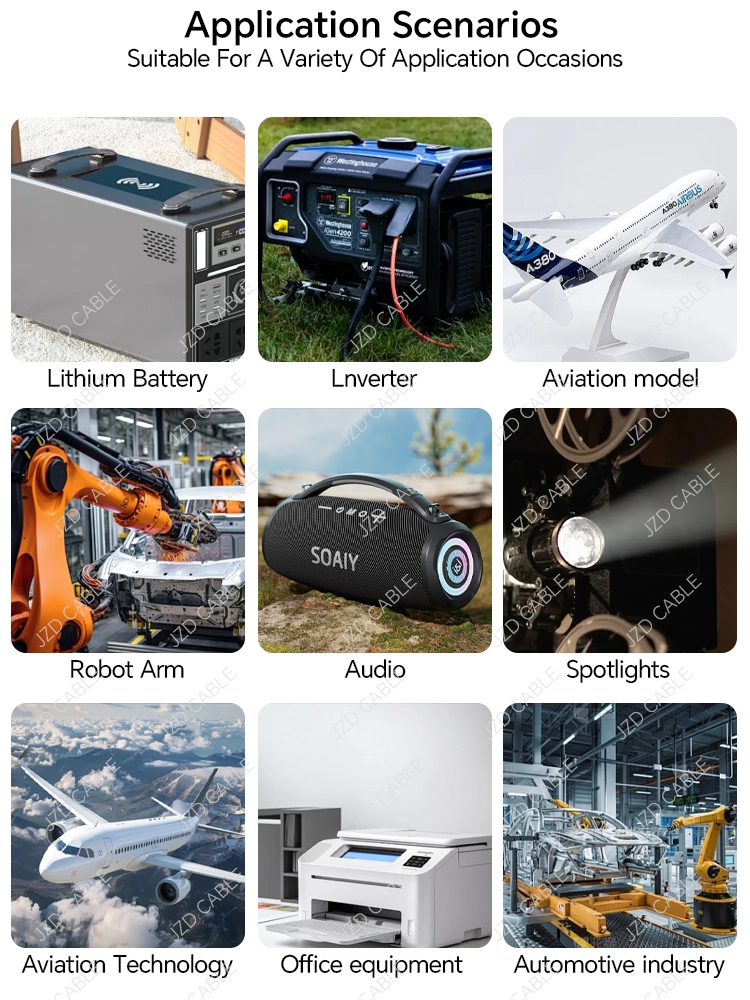

Applications

- Industrial automation: robotic arms, conveyor belts, and control panels.

- Medical equipment: surgical instruments, diagnostic machines, and monitoring systems.

- Aerospace: aircraft wiring and UAV components exposed to vibration and extreme temperatures.

- Renewable energy: solar panels, wind turbines, and energy storage systems.

Avoiding Silicone Wire Performance Mismatches

- Ignoring environmental factors like temperature, chemical exposure, and mechanical stress, which may cause rapid aging or safety hazards.

- Incorrect conductor size or voltage ratings, resulting in overheating, voltage drops, or unnecessary cost increases.

- Overlooking certifications such as UL, CE, or TÜV, potentially leading to non-compliance or risks.

- Neglecting flexibility needs for dynamic applications like robotics, causing premature fatigue.

-

Evaluating environmental conditions, mechanical requirements, and electrical specifications. -

Verifying compliance with standards and ensuring wires meet project parameters.