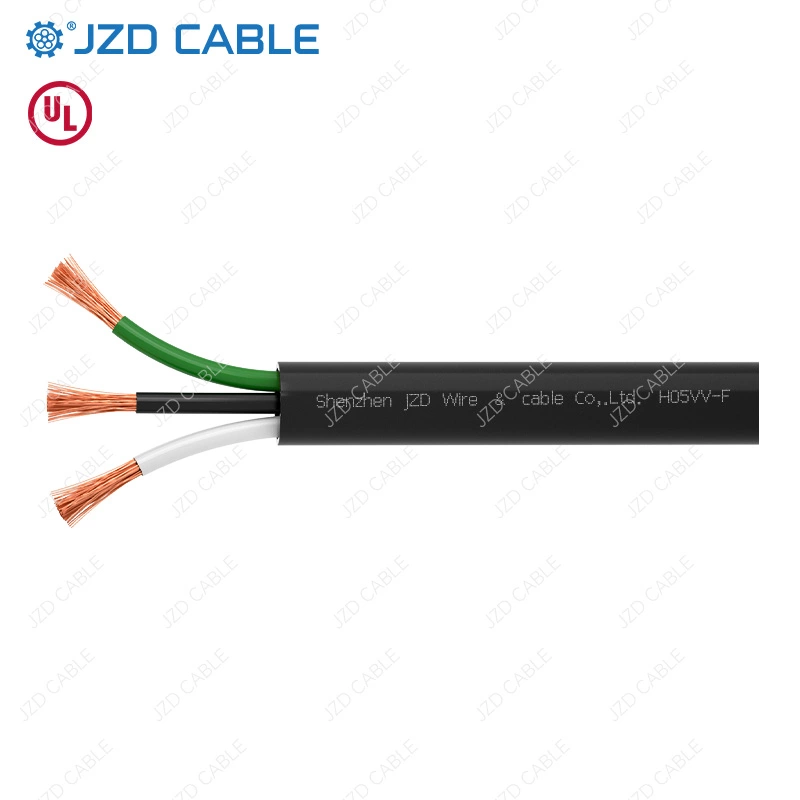

What is a 2-Core TPS Flat Cable?

Key Features and Applications of TPS Flat Cables

- The parallel core layout reduces cable thickness, making it ideal for confined spaces, such as behind appliances or in decorative installations.

- Easy to route through conduits, partitions, or furniture without bulkiness.

- Constructed with stranded copper conductors and PVC insulation, the cable remains pliable even at low temperatures, supporting frequent bending and movement.

- Resistant to minor impacts, chemicals, and moisture, suitable for household and light industrial use.

- Halogen-free materials reduce smoke and toxic fume emissions during fires, aligning with ROHS and IEC 60332-1 standards for flame retardancy.

- Certified by SAA, ensuring adherence to safety regulations.

- Lightweight and easy to strip, cut, or terminate, reducing labor time and costs.

- Compatible with standard connectors and terminals for seamless integration.

Typical Applications

- Household Appliances: Wiring for refrigerators, washing machines, and air conditioners where flat profiles prevent tangling.

- Lighting Systems: Fixed or semi-movable installations in ceilings, walls, or LED fixtures.

- Industrial Control Panels: Signal transmission and power supply in machinery, switchboards, and automation equipment.

- Temporary Setups: Events, stage lighting, and portable devices due to easy handling and storage.

Common Mistakes in Selecting TPS Flat Cables

- Incorrect Conductor Size or Voltage Rating: Undersized cables may overheat, causing voltage drops or hazards.

- Improper Installation: Excessive bending or compression can damage insulation, leading to short circuits.

- Ignoring Environmental Conditions: Temperature, chemical exposure, or mechanical stress can accelerate aging if unaccounted for.

- Using Low-Quality Cables: Cheap options may save costs initially but risk premature failure, wear, or non-compliance.

- Overlooking Certifications: Neglecting SAA approvals may violate safety standards.

How to Avoid These Pitfalls

-

Assess Environmental Needs: Evaluate temperature ranges, moisture levels, and mechanical demands. -

Verify Certifications and Specifications: Choose cables that match project parameters, such as voltage ratings and flame-retardant requirements.