What is XHHW Wire?

- Excellent Thermal Stability: Can handle higher continuous operating temperatures.

- Superior Moisture and Chemical Resistance: The XLPE insulation provides a strong barrier against water, humidity, and many corrosive elements.

- Enhanced Durability: It is generally thicker and more resistant to abrasion and crushing compared to some other insulations.

What is XHHW Cable Used For?

- Wet and Damp Locations: Conduit runs underground, in concrete slabs, or in outdoor locations where condensation or direct moisture is present.

- Commercial and Industrial Buildings: As feeders, branch circuits, and in panel boards where reliability is critical.

- Direct Burial (when specifically marked as XHHW-2, RHH/RHW-2, or USE-2): Suitable for underground runs without conduit.

- High-Temperature Areas: Environments with elevated ambient temperatures where its 90°C rating is advantageous.

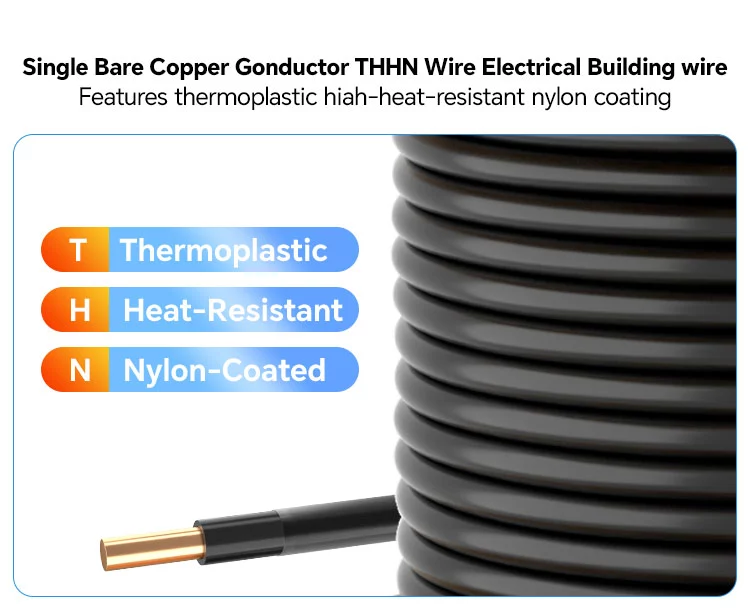

What is THHN Wire?

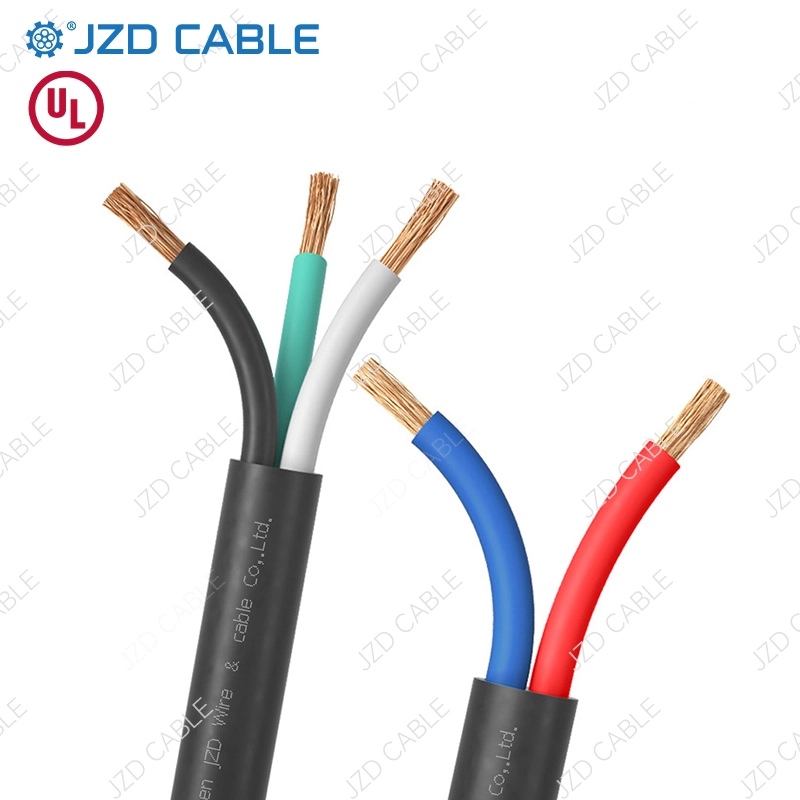

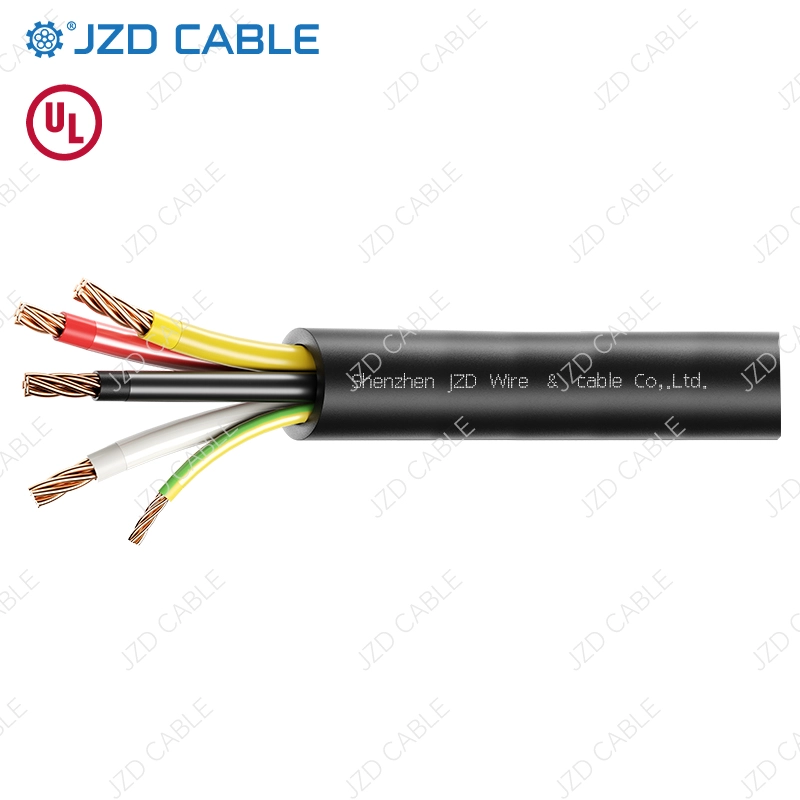

- Thermoplastic (PVC) Insulation: A polyvinyl chloride insulation that is cost-effective and flexible.

- Nylon Jacket: An outer nylon sheath that provides a smooth, tough surface for added abrasion resistance and makes the wire easier to pull through conduit.

- Thinner Overall Diameter: Typically has a thinner wall than XHHW, allowing more wires to fit in a given conduit size (better conduit fill).

What is THHN Wire Used For?

- General Purpose Wiring: Inside conduit and cable trays in residential, commercial, and industrial dry locations.

- Machine Tools and Control Circuits: Where flexibility and ease of installation are important.

- Appliance and Equipment Wiring.

- New Construction and Retrofits: Its ease of pulling makes it a favorite for electricians.

When to Use XHHW Wire vs. THHN Wire

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Choose XHHW when the installation is in a harsh environment (persistent moisture, underground, corrosive, high ambient heat) and you need maximum long-term reliability and a 90°C wet rating.

- Choose THHN/THWN-2 for standard indoor, dry applications where cost, flexibility, and ease of installation are the top priorities. For damp indoor locations, ensure you are using the THWN-2 rated version.