When specifying building wire for construction, industrial, or commercial projects, two common designations you’ll encounter are T90 and THHN. While they are often mentioned together and can look very similar, they are not interchangeable. Understanding the precise relationship between T90 and THHN is crucial for selecting the right product for safety, code compliance, and performance. This guide breaks down what they are, how they differ, and where to use them.

What is T90 Cable?

T90 is a Canadian designation (according to CSA C22.2 No. 75 standards) for a specific type of thermoplastic-insulated building wire. The “T” stands for thermoplastic, and the “90” indicates that the wire is rated for a maximum continuous conductor temperature of 90°C.

Key Characteristics of T90:

- Standard: CSA C22.2 No. 75 (Canadian).

- Temperature Rating: 90°C dry, 75°C wet/damp, 60°C in oil.

- Construction: Features a PVC (Polyvinyl Chloride) insulation with an overall nylon sheath for durability and pullability.

- Voltage Rating: Commonly rated for 600V.

- Primary Use: Designed and approved for use in Canada for general-purpose wiring in conduit, cable trays, and other recognized raceways in dry locations.

What is THHN Cable?

THHN is a very common American designation (according to UL standards, like UL 83 and the National Electrical Code NFPA 70) for a type of building wire. The letters each have a specific meaning:

- T: Thermoplastic insulation.

- H: Heat-resistant (rated to 75°C).

- HH: Higher heat-resistant (rated to 90°C).

- N: Nylon jacket over the insulation.

Key Characteristics of THHN:

- Standard: UL 83, NFPA 70 NEC (USA).

- Temperature Rating: Dual-rated for both 75°C and 90°C in dry locations.

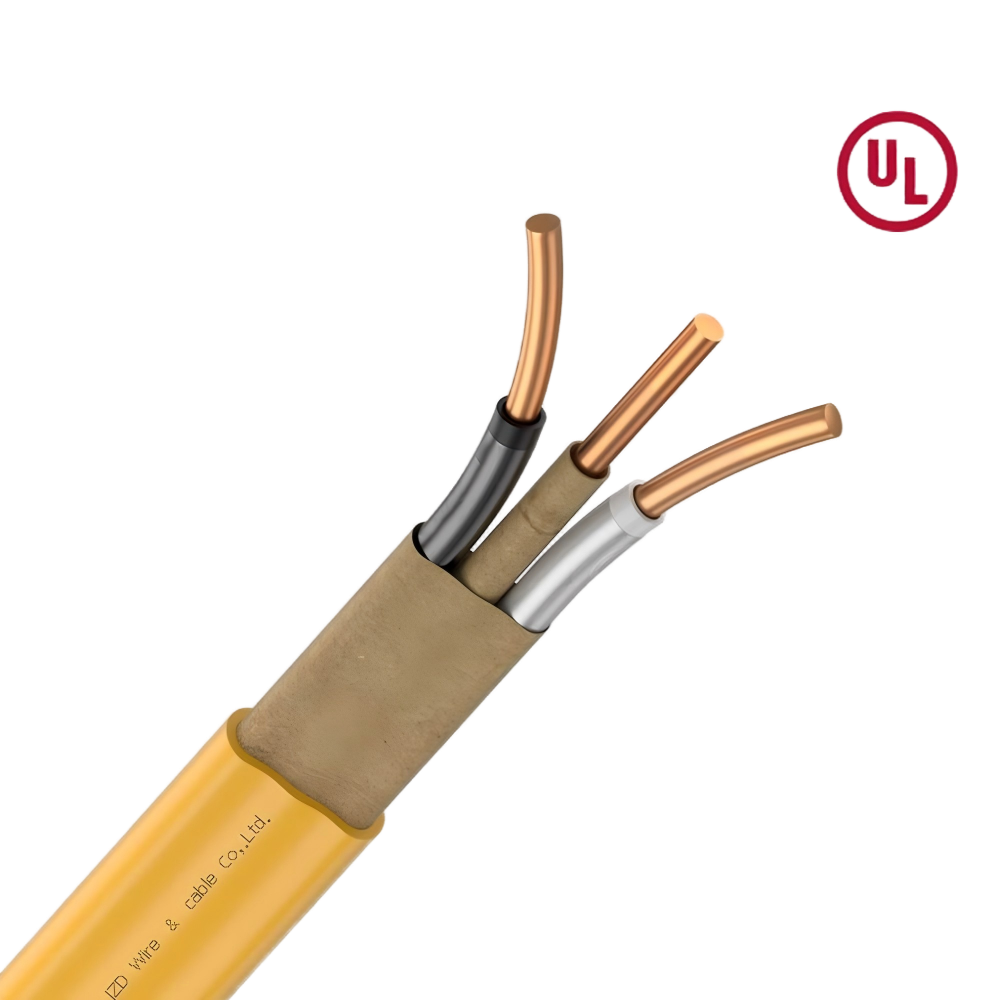

- Construction: PVC insulation with a thin, smooth nylon outer sheath. The nylon provides excellent mechanical protection, chemical resistance, and makes the wire easier to pull through conduit.

- Voltage Rating: Commonly 600V.

- Primary Use: The most widely used building wire in the United States for conduit and tray applications in dry and damp locations. Often manufactured as THHN/THWN-2, where the “W” indicates suitability for wet locations at lower temperatures.

Key Differences Between T90 and THHN

While both are thermoplastic-insulated, nylon-jacketed wires, the critical differences lie in their governing standards, ratings, and regional acceptance.

- Governing Standards & Regional Acceptance:

- T90 is a Canadian (CSA) standard wire. It is the default choice for construction in Canada and may not be directly recognized under U.S. codes without special evaluation.

- THHN is an American (UL/ANSI) standard wire. It is the default choice in the United States and is widely accepted in international markets following U.S. standards.

- Wet Location Rating:

- This is a major practical difference. A standard T90 rating is for dry locations only. For wet locations in Canada, a different designation like TW75 or RW90 is typically used.

- Many THHN wires are manufactured as a dual-rated THHN/THWN-2. The THWN-2 rating is critically important as it means the wire is approved for use in both dry and wet locations at up to 90°C, offering superior versatility.

- Name and Code Recognition:

-

- The “N” in THHN explicitly stands for the Nylon jacket, clearly defining this feature in its name per UL/ANSI standards.

- The “T90” designation under CSA standards implies the 90°C rating with thermoplastic insulation; the presence of a nylon sheath is a standard construction feature but is not explicitly called out in the short designation like it is with THHN.

What Do T90 and THHN Have in Common?

The similarities are why they are often compared and can be visually confused.

- Core Material: Both typically have bare copper or aluminum conductors.

- Basic Construction: Both use PVC (Thermoplastic) insulation and feature a protective nylon outer sheath. This gives them a similar feel and appearance.

- Primary Application: Both are used as building wire for power and lighting circuits, installed inside conduit, metal-clad cable, or other protected raceways.

- Dry Location Rating: Both are rated for 90°C in dry locations, allowing for similar ampacity correction factors.

Conclusion: Choosing the Right Cable

The choice between T90 and THHN is primarily dictated by local electrical codes, the project location, and the need for wet location rating.

- For projects in Canada: Specify CSA-approved T90 for standard dry location applications. For wet locations, a different CSA cable type (like RW90) is required.

- For projects in the USA and most international markets: UL-listed THHN/THWN-2 is the universal and versatile choice. Its dual rating for 90°C in both dry and wet locations makes it a more flexible, all-in-one solution for many applications, which is a key advantage over standard T90.

Comparison Table: T90 vs. THHN at a Glance

|

Feature

|

T90 Cable

|

THHN/THWN-2 Wire

|

|---|---|---|

|

Governing Standard

|

CSA C22.2 No. 75 (Canada)

|

UL 83, ANSI/NFPA 70 (USA)

|

|

Max Temp (Dry)

|

90°C

|

90°C

|

|

Max Temp (Wet)

|

75°C

|

90°C (as THWN-2)

|

|

Insulation

|

PVC

|

PVC

|

|

Outer Sheath

|

Nylon

|

Nylon

|

|

Key Identifier

|

“T90” Printing on Sheath

|

“THHN” or “THWN-2” on Sheath

|

|

Primary Market/Code

|

Canada (CSA)

|

USA & International (UL/NEC)

|

|

Wet Location Use

|

No (Requires different CSA type)

|

Yes (when rated THWN-2)

|

Source Your Quality Building Wire from JZD Cable

Navigating wire specifications requires expertise. At JZD Cable, we manufacture high-performance cables that meet precise standards. We produce both CSA-compliant T90 cables and versatile UL-listed THHN/THWN-2 wires to suit your project’s needs and local codes.

Our cables feature:

- Precision-drawn copper conductors for optimal conductivity.

- High-grade, flame-retardant PVC compounds.

- Durable nylon sheathing for excellent pullability and protection.

- Clear, permanent printing for easy identification and compliance.

Need a quote or have technical questions? Visit our website at jzdcable.com to explore our full product range and contact our expert team. Let JZD Cable be your trusted partner for reliable wiring solutions.