In the world of electrical wiring, selecting the right cable type is crucial for safety, compliance, and performance. Two commonly used and sometimes confused cable types are MC (Metal-Clad) Cable and AC (Armored Cable, often referring to “AC” as in “Armored Clad” or the traditional “BX” style). While they may look similar at a glance, they serve under different standards, have distinct constructions, and are suited for specific applications. This blog will clarify what MC Cable and AC Cable are, explore their similarities and differences, and provide guidance on selecting the right cable for your needs.

What is MC Cable?

MC Cable (Metal-Clad Cable) is a versatile and widely used assembly of insulated circuit conductors (typically THHN/THWN) enclosed within a flexible interlocked or corrugated metal armor, usually made of aluminum or steel. A key feature of modern MC cables is that they also include a dedicated green insulated or bare copper equipment grounding conductor within the assembly. This design eliminates the need for a separate external ground and provides reliable grounding through the cable itself.

MC Cable is governed by Article 330 of the National Electrical Code (NEC). It is approved for a wide range of applications, including indoor and outdoor use (with appropriate ratings), exposed and concealed work, in cable trays, and even in some hazardous locations when specifically listed for such use. Its flexibility, durability, and all-in-one grounding make it a favorite for commercial, industrial, and multi-residential construction.

What is AC Cable?

AC Cable (Armored Cable), traditionally known as “BX” (a legacy trademark), is an earlier generation of armored cable. Its standard construction consists of insulated conductors wrapped in a spiral-wound, flexible metal armor. The critical historical distinction of traditionalAC Cable is that the metal armor itself serves as the equipment grounding path. It did not originally include a separate, dedicated grounding conductor within the assembly.

AC Cable is covered under NEC Article 320. Modern versions, often called “ACL” (Armored Cable with a ground wire), now include a bonding strip or a separate aluminum ground wire under the armor to improve grounding reliability. However, the classic “AC” designation is still associated with the armor-as-ground method. Its use is more restricted by the NEC compared to MC Cable and is generally limited to dry indoor locations, not in damp or corrosive environments.

Commonalities Between MC and AC Cable

Despite their differences, MC and AC cables share several important characteristics:

- Metal Armor: Both feature a flexible metal jacket (aluminum or steel) that provides superior physical protection against crushing, punctures, and rodent damage compared to non-metallic sheathed cables (like NM or Romex®).

- Applications: Both are used for branch circuits and feeders in commercial and industrial settings, often in exposed runs where conduit might be less economical.

- Installation: They offer easier and faster installation than pulling wires through rigid conduit, especially in retrofit or complex routing situations.

- Aesthetics: The metal armor provides a clean, industrial look that is often preferred in visible installations like warehouses, lofts, or mechanical rooms.

Key Differences Between MC Cable and AC Cable (with Comparison Table)

The differences are critical for code compliance and safety. The table below summarizes the main distinctions:

|

Feature

|

MC Cable (Metal-Clad)

|

AC Cable (Armored, Traditional “BX”)

|

|---|---|---|

|

Governing NEC Article

|

Article 330

|

Article 320

|

|

Grounding Method

|

Includes a dedicated insulated/bare equipment grounding conductor inside the armor.

|

Traditionally, the metal armor acts as the ground. Modern “ACL” has a bonding strip/aluminum ground.

|

|

Grounding Reliability

|

High. A dedicated ground ensures a low-impedance, reliable path.

|

Potentially less reliable. Dependent on armor continuity; connections can loosen over time.

|

|

Moisture & Corrosion

|

Can be listed for wet/damp locations (look for “MC” with a corrosion-resistant jacket or aluminum armor).

|

Generally restricted to dry locations only. The armor is not suitable for damp, wet, or corrosive areas.

|

|

Internal Construction

|

Conductors are individually wrapped. May include a plastic wrap or anti-short bushings at ends.

|

Contains a kraft paper wrap around conductors and may require redheads (insulating bushings) to protect wires from the cut armor.

|

|

Versatility

|

Highly versatile. Approved for indoor, outdoor, exposed, concealed, cable tray, and some hazardous (if listed).

|

Less versatile. Primarily for dry, indoor, exposed or concealed work (not in damp masonry, etc.).

|

|

Cost

|

Generally higher due to more robust construction and included ground wire.

|

Often slightly lower cost.

|

The Core Distinction: The most significant difference lies in the grounding method. MC Cable’s dedicated ground wire is a safer, more modern standard. Relying on the armor for grounding (as in traditional AC) can be risky if connections degrade.

Selection Guide: MC Cable or AC Cable?

Choosing the right cable depends on your project’s specific requirements, local codes, and environment.

Choose MC Cable if:

- Your installation is in a damp, wet, or corrosive location (use appropriate wet-listed MC).

- You require a cable for outdoor use or in cable trays.

- The project demands the highest reliability for grounding and safety.

- You are working on a commercial, industrial, or multi-family building where modern codes and versatility are paramount.

- You need to future-proof the installation for maximum flexibility and code acceptance.

AC Cable might be considered if:

- The project is a simple, dry, indoor residential or light commercial retrofit where local code still permits its use.

- Budget is a primary constraint, and the application is low-risk.

- You are specifically working on a renovation where matching existing “BX” type wiring is necessary.

Recommendation:For the vast majority of new construction and commercial/industrial projects, MC Cable is the recommended and superior choice. Its dedicated ground, environmental versatility, and broader NEC acceptance make it the safer, more reliable, and more flexible solution. Always consult the latest NEC and a qualified electrical professional.

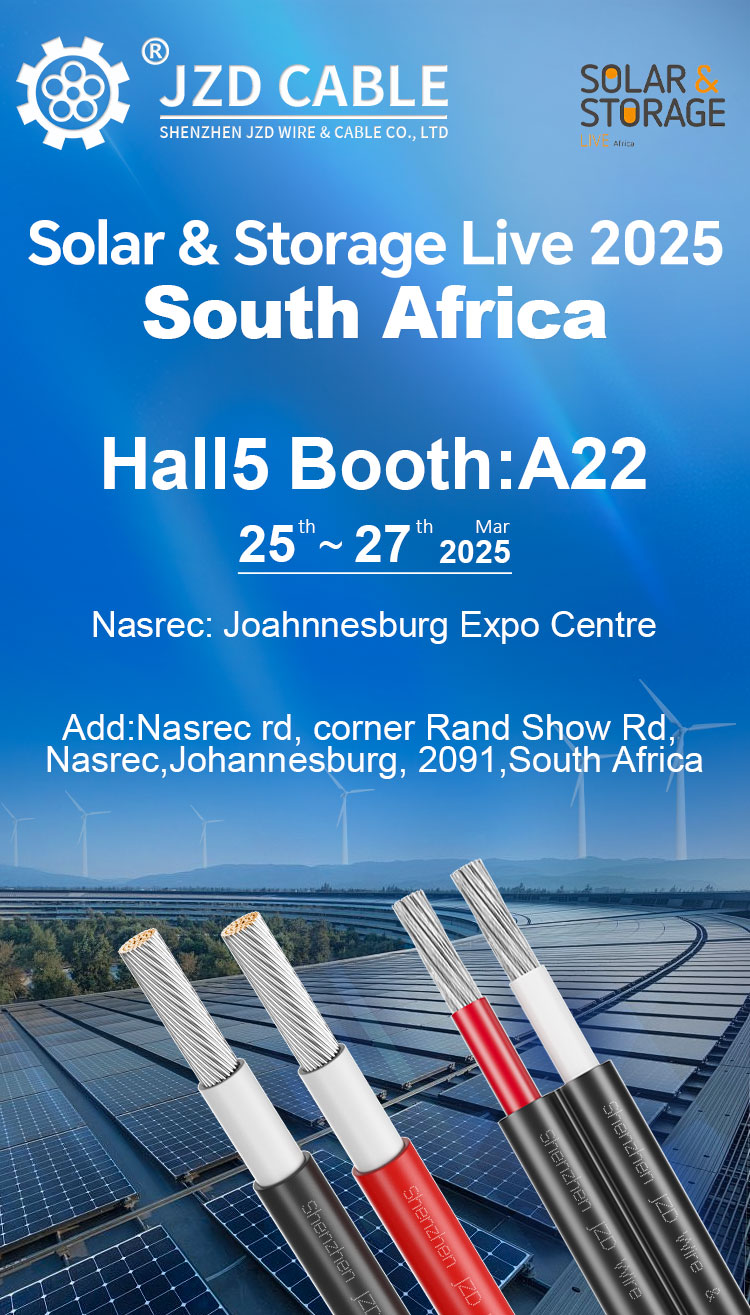

Trust Your Project to JZD Cable’s Quality Wiring Solutions

At JZD Cable, we specialize in manufacturing high-performance, code-compliant electrical cables for demanding applications. Our range of UL-listed MC Cables is engineered for durability, safety, and ease of installation. Whether you’re an electrical contractor, project engineer, or distributor, you can trust our products to meet the highest industry standards.

Choose JZD Cable for:

- Premium MC Cables with reliable dedicated grounding.

- Cables built to exacting NEC, UL, and CSA standards.

- Customization options to meet your specific project needs.

- Expert support and reliable supply for your business.

Ready to power your next project with confidence? Browse our product catalog or contact our team today to find the perfect cable solution. Visit us at jzdcable.com.