When planning an overhead power distribution system, one of the most critical decisions is choosing between aerial insulated cables and traditional bare overhead conductors. Each option offers distinct advantages and limitations, depending on the application environment, safety requirements, and long-term operational costs. In this article, we break down the key differences to help you make an informed choice.

What Are Aerial Insulated Cables?

Aerial insulated cables, such as ABC (Aerial Bundled Cable), feature insulated conductors—typically made of aluminum or aluminum alloy—encased in UV-resistant materials like cross-linked polyethylene (XLPE) or high-density polyethylene (HDPE). These cables are designed for low- to medium-voltage overhead systems and are widely used in both urban and rural settings.

Key Features:

- Insulation Layer: Provides protection against short circuits, moisture, UV radiation, and physical contact.

- Lightweight & Flexible: Easy to install in challenging terrains like hills, forests, or dense urban areas.

- Enhanced Safety: Reduces risks related to wildlife interference, vegetation contact, and accidental human touch.

- Long Lifespan: Resists environmental wear, offering a service life of 15+ years.

What Are Bare Overhead Conductors?

Bare overhead conductors are uninsulated wires, usually made of aluminum or aluminum alloy, and are supported by poles or towers. They are a traditional choice for high-voltage transmission lines across open areas.

Key Features:

- Cost-Effective Initial Investment: Lower upfront costs compared to insulated cables.

- High Conductivity: Suitable for long-distance power transmission with minimal energy loss.

- Minimal Maintenance in Low-Risk Areas: Performs well in environments without dense vegetation or wildlife.

- Vulnerability to External Factors: Prone to corrosion, short circuits from environmental contact, and faster aging.

Key Differences Between Aerial Insulated Cables and Bare Conductors

|

Aspect

|

Aerial Insulated Cables

|

Bare Overhead Conductors

|

|---|---|---|

|

Safety

|

High—prevents short circuits and electrocution risks

|

Low—exposed conductors pose safety hazards

|

|

Lifespan

|

15+ years (resists weathering and corrosion)

|

~5 years (susceptible to environmental damage)

|

|

Installation Flexibility

|

Ideal for cramped urban spaces and complex terrains

|

Requires wide clearance; limited to open areas

|

|

Environmental Resistance

|

Excellent—withstands moisture, UV rays, and wind

|

Poor—requires additional protection in harsh conditions

|

|

Maintenance Costs

|

Low—reduced need for repairs and replacements

|

High—frequent inspections and repairs needed

|

|

Ideal Applications

|

Urban grids, rural electrification, temporary power

|

High-voltage transmission lines in open areas

|

Why Choose Aerial Insulated Cables?

-

Superior Safety: The insulated design minimizes the risk of faults, making it ideal for populated areas.

-

Adaptability: Performs reliably in diverse environments, including coastal regions and forests.

-

Long-Term Economy: Lower maintenance and replacement costs outweigh the initial investment.

-

Compliance with Modern Standards: Meets international safety and efficiency regulations.

When Are Bare Conductors a Better Fit?

- For high-voltage transmission over long distances in open, low-risk areas.

- When budget constraints prioritize initial cost savings over long-term maintenance.

- In projects where environmental factors (e.g., vegetation, wildlife) are minimal.

Why Trust JZD Cable for Your Overhead Power Needs?

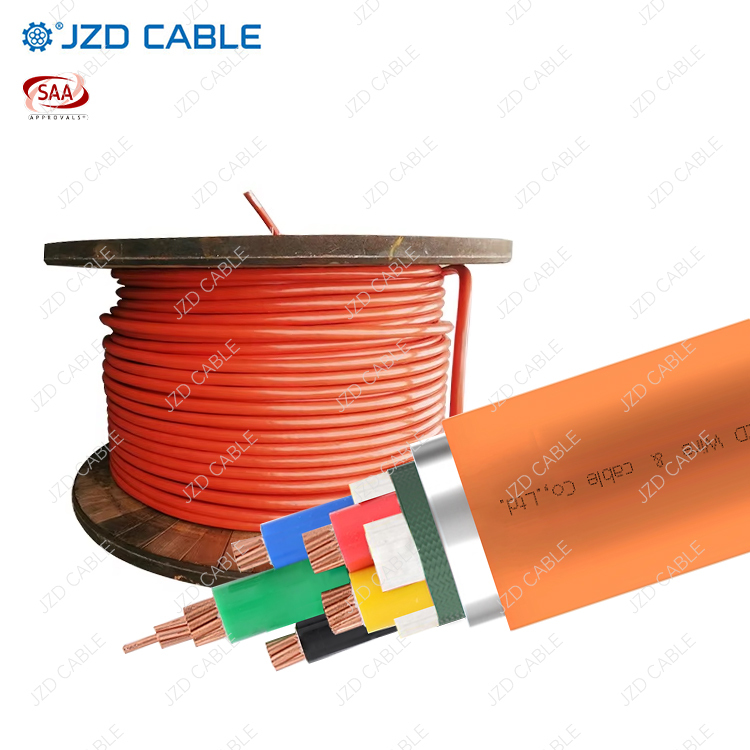

At JZD Cable, we specialize in manufacturing high-quality aerial insulated cables that comply with GB/CNS, ASTM, ICEA, and UL standards. Our products are engineered for:

- Durability: Resistant to extreme weather and mechanical stress.

- Ease of Installation: Lightweight designs reduce labor and time costs.

- Custom Solutions: Tailored cables for specific project requirements.

Whether you’re upgrading an urban grid or deploying a rural electrification project, JZD Cable provides reliable, efficient, and safe solutions.