In fire safety engineering, the reliability of a Fire Alarm System (FAS) depends fundamentally on the performance of its cabling infrastructure. When exposed to extreme heat and flames, conventional cables fail rapidly, potentially compromising entire emergency response protocols. This analysis examines the specific technical functions of certified fire alarm cables, with particular focus on SAA-compliant solutions as supplied by JZD Cable.

1. Maintaining Circuit Integrity Under Thermal Stress

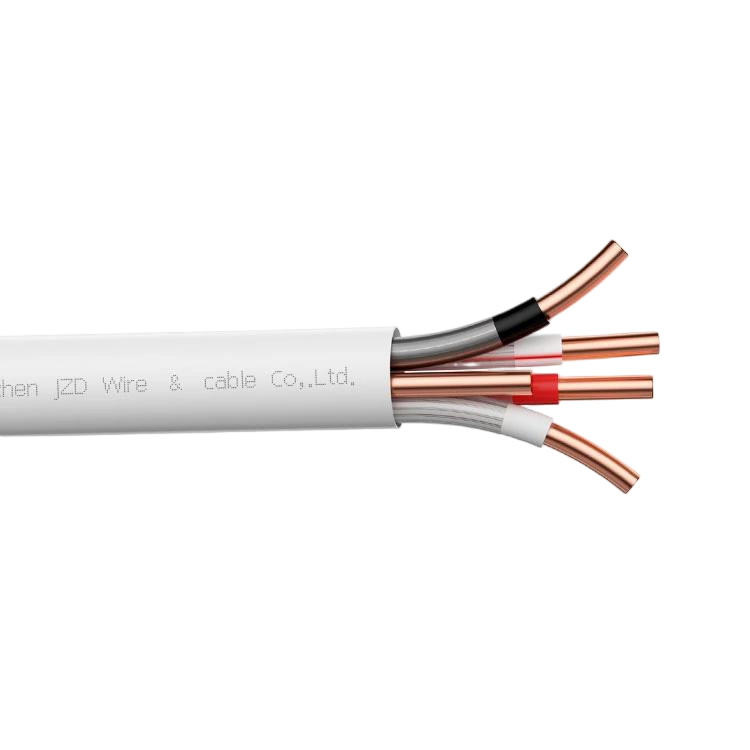

The primary function of a fire alarm cable is to preserve electrical continuity and signal transmission capability during a fire event. Standard cables typically fail at temperatures exceeding 300°C due to insulation melting and conductor degradation. In contrast, SAA-certified fire alarm cables incorporate multiple protective layers:

- Synthetic mica tape wrapping around stranded annealed copper conductors provides initial thermal barrier protection.

- Ceramic-forming insulation materials create a stable, heat-resistant structure when exposed to temperatures up to 950°C.

- Circuit integrity is maintained for a minimum of 90 minutes, ensuring continuous operation of detection and alarm circuits as required by AS 1674 and related standards.

2. Ensuring Signal Transmission for Life Safety Systems

Beyond mere circuit preservation, these cables must guarantee signal integrity for critical FAS components:

- Detector-to-panel communication: Ensuring smoke/heat detector signals reach the fire control panel without degradation.

- Alarm activation: Reliable transmission to audible/visual warning devices throughout the evacuation timeline.

- Emergency system integration: Supporting interfaces with sprinkler systems, elevator recall, and ventilation controls.

Voltage stability is maintained through robust 450/750V-rated insulation, while the operational temperature range (-25°C to 110°C) ensures performance across various environmental conditions.

3. Toxic Fume Suppression and Visibility Preservation

The selection of cable materials directly impacts occupant safety during evacuation:

- Low Smoke Zero Halogen (LSZH) compounds limit smoke density to below 60% (per IEC 61034) and halogen acid gas emission to under 0.5% (per IEC 60754).

- This reduction in opaque smoke and corrosive gases maintains critical visibility levels in escape routes and prevents secondary damage to electronic equipment.

4. Compliance and Certification Imperatives

The use of non-certified cables constitutes a significant liability. SAA certification involves rigorous testing including:

- Flame propagation resistance (AS/NZS 5000 series)

- Circuit integrity maintenance under fire conditions

- Third-party validation by accredited bodies such as Global-Mark

Engineering Solutions from JZD Cable

JZD Cable’s SAA Fire Alarm Cable range incorporates advanced engineering features:

- Dual-layer protection system combining mica barriers with LSZH thermoset materials

- Exceeds minimum circuit integrity requirements with 90+ minute performance ratings

- Full compliance documentation with batch-traceable quality assurance

For detailed technical specifications or project-specific consultations, contact our engineering team at https://jzdcable.com.