Selecting the right cable is not just a detail—it’s a fundamental decision for the safety, efficiency, and longevity of your solar energy installation. While ordinary PVC wire is common for indoor electrical work, photovoltaic (PV) systems demand a specialized solution: the solar cable. This guide breaks down the key differences to help you make an informed choice.

Technical Specifications at a Glance

|

Feature

|

Photovoltaic (PV) Cable

|

Ordinary PVC Wire

|

|---|---|---|

|

Conductor

|

Tinned Copper

|

Bare Copper or Aluminum

|

|

Insulation & Sheath

|

Irradiation Cross-Linked Polyolefin (XLPO)

|

Polyvinyl Chloride (PVC)

|

|

Voltage Rating

|

Up to 1500V DC (PV System Optimized)

|

Typically ≤ 750V AC (Poor DC Suitability)

|

|

Temperature Range

|

-40°C to +120°C (Long-term)

|

-15°C to +70°C

|

|

UV & Weather Resistance

|

Excellent (25+ years outdoors)

|

Poor (Degrades in 1-2 years outdoors)

|

|

Flexibility & Durability

|

High Flexibility, Crack-Resistant

|

Moderate, Prone to Crack When Bent

|

|

Safety & Environmental

|

Halogen-Free, Low Smoke, RoHS/TUV Certified

|

Contains Halogens, Emits Toxic Fumes When Burned

|

|

Typical Lifespan

|

25 Years

|

10-15 Years (Indoor), 1-2 Years (Outdoor)

|

Detailed Breakdown: Why Solar Cable is the Superior Choice

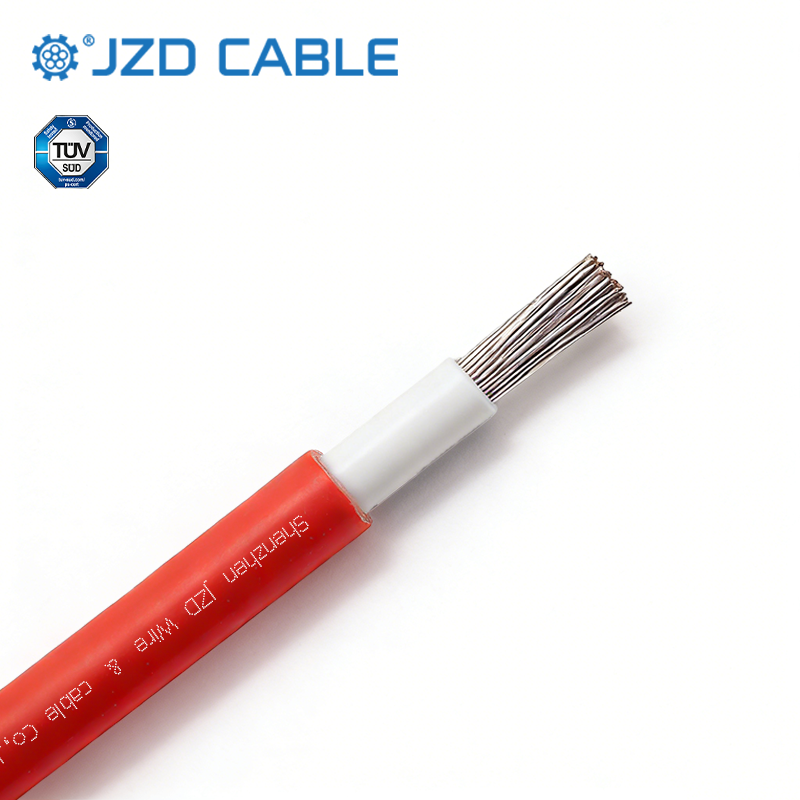

1. Conductor Material: Tinned Copper vs. Bare Copper

- Solar Cable: Uses tinned copper. The tin coating prevents oxidation and corrosion, which is crucial for maintaining a stable connection over decades in humid or variable outdoor environments.

- PVC Wire: Often uses bare copper or aluminum. Bare copper can oxidize over time, increasing resistance and connection heat—a significant risk for long-term, high-current DC applications.

2. Insulation & Sheath: XLPO vs. PVC

This is the most critical difference.

- Solar Cable: Features Irradiation Cross-Linked Polyolefin (XLPO). This material is exceptionally tough, flexible, and resistant to heat, cold, and sunlight. It won’t crack in freezing temperatures or soften and deform under the intense heat on a solar panel array.

- PVC Wire: Uses standard PVC. It becomes brittle in cold weather and can soften, distort, or melt at sustained high temperatures, leading to insulation failure and short circuits.

3. Designed for DC: High Voltage & Weather Endurance

- Solar Cable: Engineered for the high-voltage DC environment of solar arrays (up to 1500V DC). Its XLPO insulation offers superior resistance to electrical stress and potential arcing. Combined with outstanding UV, ozone, and salt mist resistance, it is built to withstand direct sunlight and harsh weather for over 25 years.

- PVC Wire: Rated for lower AC voltages. Its insulation degrades rapidly under UV exposure, often cracking within 1-2 years outdoors. It is not designed for the constant DC stress and temperature extremes of a PV system, leading to premature failure and safety hazards.

4. Safety, Certification, and Long-Term Value

- Solar Cable: Certified to stringent international standards for photovoltaic applications (like TUV). It is typically halogen-free. In the rare event of a fire, it emits very low smoke and no toxic acidic gases, protecting both people and equipment.

- PVC Wire: Contains halogens. When burned, it releases toxic and corrosive gases like hydrogen chloride, posing a severe health risk and damaging electronic components.

- Lifespan: The 25-year service life of a quality solar cable matches the warranty of your solar panels, eliminating costly and risky replacements. Using PVC wire outdoors guarantees early failure.

Conclusion: The Right Wire for the Right Job

The choice is clear. Ordinary PVC wire is unsuitable for outdoor photovoltaic applications. Its material properties and safety profile do not meet the demanding, long-term requirements of a solar power system.

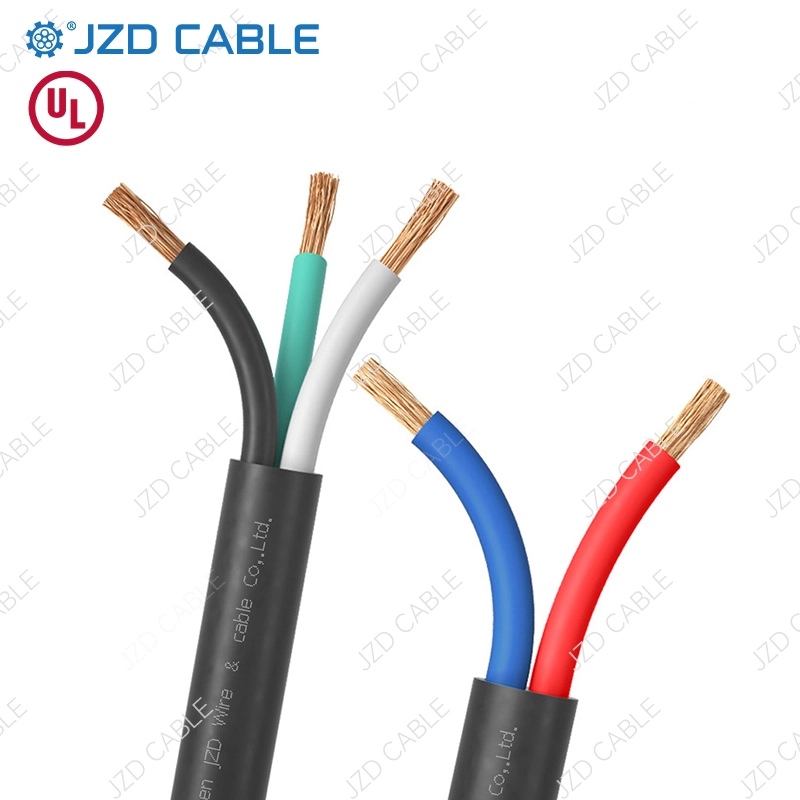

For any part of your PV system exposed to sunlight, weather, or carrying DC current— including connections between panels, runs to combiners, and links to inverters—you must use certified solar cable. It is an investment in the safety, reliability, and maximum energy yield of your solar installation for decades to come.

At JZD Cable , we specialize in manufacturing high-performance, certified solar cables that meet global standards. Ensure your project’s foundation is as robust as your energy goals. Contact us for the right cable solution.