In the world of photovoltaic (PV) systems, every component’s reliability is critical. For solar cables, the insulation material is the frontline defense against harsh outdoor environments. Two prevalent materials dominate the conversation: XLPE (Cross-Linked Polyethylene) and XLPO (Cross-Linked Polyolefin). While both are superior irradiated cross-linked polyolefins compared to standard PVC, they are not created equal. This blog will break down their key differences to help you make an informed choice for your solar project.

At first glance, both materials share a core process: they undergo electron beam irradiation to create a stable, cross-linked molecular structure. This gives them excellent thermal and mechanical properties far beyond ordinary insulation. However, their material composition and resulting performance are tailored for different applications.

Core Differences at a Glance

|

Category

|

XLPE (Cross-Linked Polyethylene)

|

XLPO (Cross-Linked Polyolefin)

|

|---|---|---|

|

Material Essence

|

Based on Polyethylene (PE) resin, modified via irradiation.

|

Based on Polyolefin Elastomer (POE) alloyed with PE, then cross-linked. A purpose-engineered material.

|

|

Long-Term Temp Rating

|

Standard 120°C, suitable for general PV use.

|

Upgraded 125-130°C, offering superior high-temperature stability.

|

|

Short-Term/Peak Temp

|

Up to 150°C (short-term overload).

|

Up to 150-180°C, with better resistance to瞬时高温.

|

|

Low-Temp Flexibility

|

Functional at -40°C, but may become stiff. Risk of micro-cracks when bent in cold conditions.

|

Maintains high flexibility from -40°C to -50°C. No brittleness risk, ideal for winter installation.

|

|

Weather & UV Resistance

|

General-grade UV resistance. Requires extra anti-aging additives. May chalk or degrade long-term.

|

PV-dedicated UV配方. Excellent resistance to ozone, salt spray, and UV. Can withstand over 25 years of outdoor exposure.

|

|

Flexibility & Mechanical

|

Moderately hard with medium flexibility. Insulation may fatigue under repeated bending.

|

Low hardness, high elasticity. Excellent flexibility, withstands thermal expansion/contraction of PV panels without cracking.

|

|

Chemical Resistance

|

Resistant to water and common chemicals. Moderate tolerance to PV electrolyte and acid rain.

|

Superior resistance to electrolyte, acid rain, coastal salt mist, and soil microorganisms.

|

|

Electrical Performance

|

Good insulation resistance & dielectric strength, suitable for 1500VDC systems.

|

Enhanced 耐电晕 and anti-tracking性能. Lower risk of insulation breakdown under DC high voltage.

|

|

Cost

|

Lower cost (approx. 10-20% less than XLPO). A通用工业级 material.

|

Higher cost due to specialized formulation. The mainstream choice for premium PV cables.

|

|

Primary Application

|

General-purpose industrial insulation for various applications.

|

PV-dedicated insulation, tailored for harsh outdoor solar environments.

|

Choosing the Right Insulation for Your PV Project

The choice between XLPE and XLPO isn’t just about specs—it’s about project requirements, environment, and total cost of ownership.

When XLPO is the Recommended Choice:

XLPO is the de facto standard for modern, durable PV installations. Choose XLPO if your project involves:

- Long-Term Warranty & Durability: You require a system lifecycle of 25+ years with minimal maintenance.

- Harsh Environments: Coastal areas (high salt mist), industrial zones (pollution), or regions with high UV index and extreme temperature swings.

- Demanding Installations: Complex racking with frequent bends, or locations where cables are subject to constant movement from thermal cycling.

- High System Voltage: For large-scale utility or commercial projects where electrical stability and safety are paramount.

When XLPE Can Be a Viable Option:

XLPE remains a competent and cost-effective material. It can be suitable for:

- Small-scale or Budget-Conscious Projects: Where initial cost is a primary driver.

- Less Demanding, Sheltered Environments: For example, in某些 protected residential rooftop setups in temperate climates.

- General-Purpose Wiring within combiner boxes or in protected conduits, though dedicated PV wire is always preferred.

Conclusion

While both XLPE and XLPE provide a solid foundation for solar cable performance, XLPO represents a targeted evolution for photovoltaic applications. Its enhanced blend of temperature resistance, exceptional flexibility, and superior environmental protection makes it the insulation of choice for ensuring long-term, reliable power generation.

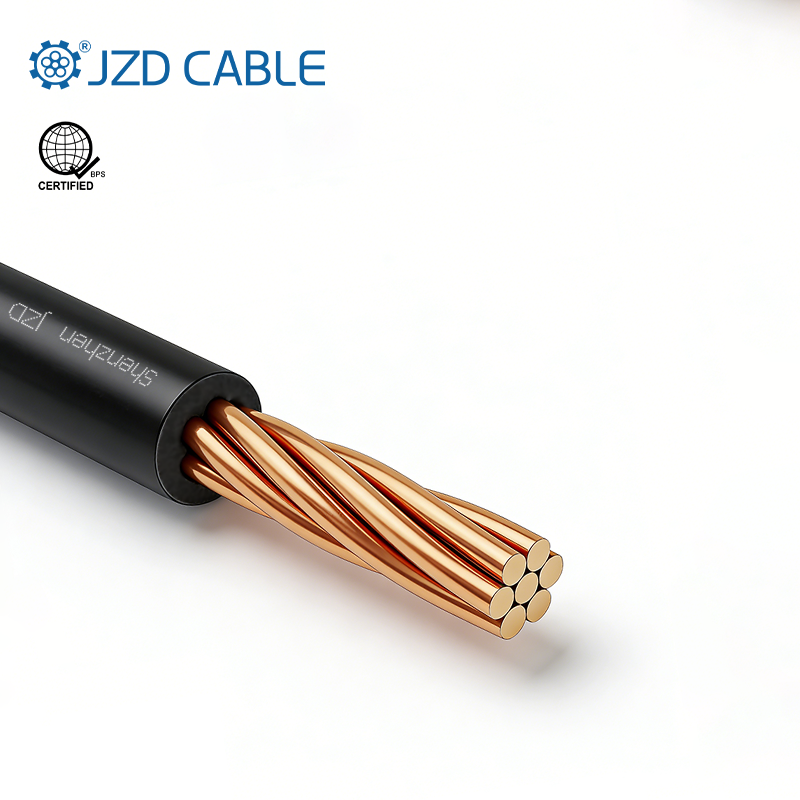

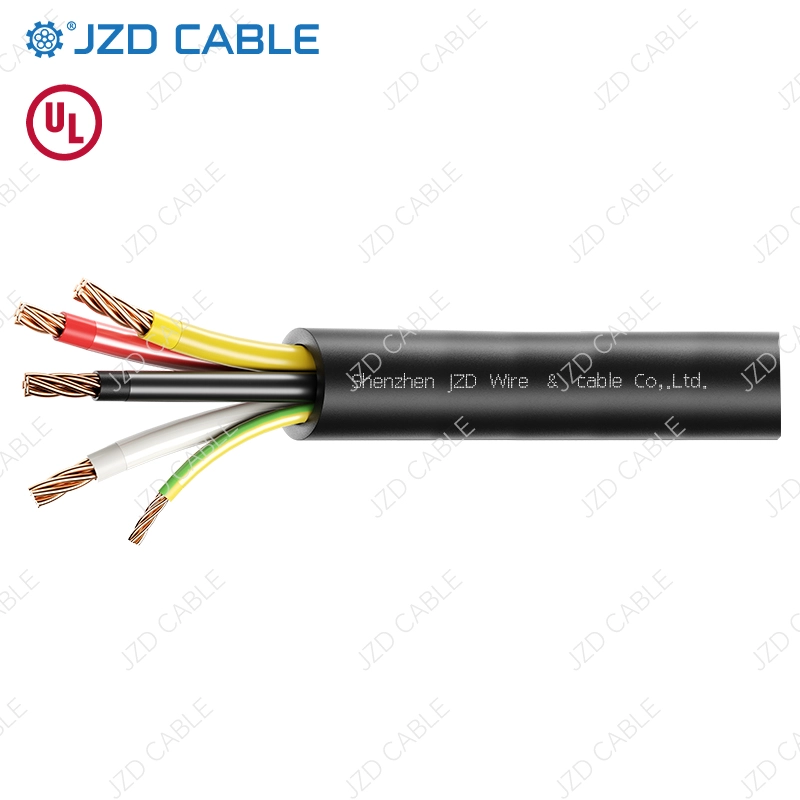

At JZD Cable our focus is on delivering reliability. We primarily utilize XLPO insulation in our H1Z2Z2-K series solar cables to ensure they meet the rigorous demands of today’s PV systems, offering peace of mind for decades. For a tailored recommendation for your specific project needs, contact our technical team today.