Photovoltaic (PV) wire, the essential single-conductor cable connecting solar panels within photovoltaic systems, relies heavily on the material at its core for performance, safety, and long-term value. While both aluminum (Al) and copper (Cu) conductors are used within the PV wire industry, their inherent properties lead to significant differences impacting installation, cost, and system efficiency. Although the lower upfront material cost of aluminum might initially seem appealing, a deeper examination reveals why copper-core PV wire is often the more practical and cost-effective choice overall, despite its higher per-meter price.

Fundamental Similarities and the Critical Difference

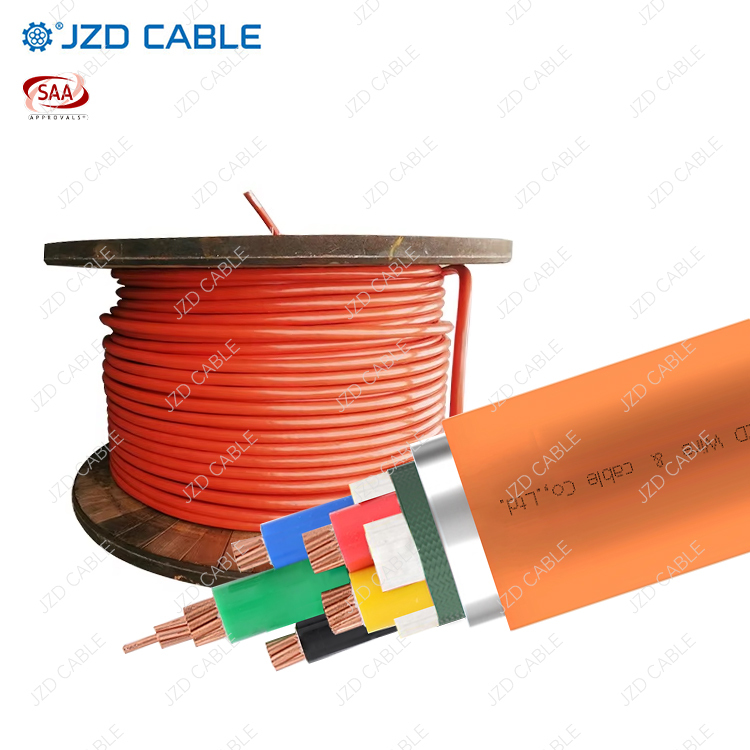

At first glance, aluminum and copper PV wires share several key characteristics essential for solar applications. Both typically feature insulation made from cross-linked polyethylene (XLPE), renowned for its durability and resistance to harsh environmental conditions. This insulation provides crucial protection against sunlight (UV resistance), flame retardancy, oil and gasoline exposure, and even suitability for direct burial applications. Both types of wire are also rated for standard photovoltaic system voltages (commonly 600V, 1000V, or 2000V). The fundamental divergence lies in the core material’s electrical conductivity.

Aluminum possesses only about 61% of the conductivity of copper. This inherent physical property means that an aluminum-core PV wire must have a significantly larger cross-sectional area (a thicker conductor) compared to its copper counterpart to carry the same electrical current (ampacity) safely without exceeding its rated temperature limits. This difference in required size cascades into several practical implications for solar installations.

Practical Implications of the Conductivity Gap

The necessity for larger aluminum conductors introduces complexities that often negate its initial cost advantage and can even lead to higher overall project expenses. Because aluminum wire must be thicker to achieve the same current-carrying capacity as copper, installers will require more physical cable or larger gauge sizes for the same power transmission. This directly impacts material costs beyond just the wire itself.

Using bulkier aluminum cable frequently necessitates larger conduits, trenches, and junction boxes to accommodate the increased physical volume. This adds to material and infrastructure costs. Furthermore, pulling thicker, stiffer cables is generally more labor-intensive and time-consuming than installing more flexible, smaller-diameter copper wire. The increased labor time translates directly into higher installation costs, which can quickly offset any savings gained on the raw wire material. Project scalability is also affected; if future expansion is anticipated, the space-saving nature of copper wiring allows for easier upgrades within existing conduit systems compared to the bulkier aluminum alternative.

Additional Advantages of Copper-Core PV Wire

Beyond the core issues of size and ampacity, copper PV wire offers other significant benefits. Grounding integrity is paramount in electrical systems. Most grounding lugs and components are made from copper. Using aluminum PV wire can create compatibility issues at grounding connections, potentially requiring special bi-metallic lugs or complex adaptations to ensure a safe and code-compliant bond. These additional components and procedures add cost and complexity. Copper-to-copper connections are inherently simpler and more reliable.

Supply chain reliability is another practical consideration. High-quality, TUV or UL-certified copper PV wire is generally more readily available from established domestic manufacturers and distributors like JZD Cable. Aluminum PV wire production can sometimes be concentrated in less accessible locations, potentially leading to longer lead times or availability challenges, especially in high-demand periods. Copper offers greater procurement stability.

Security is also a factor, albeit secondary. While both types of cable can be targeted, the significantly higher scrap value of copper makes it more attractive to thieves. However, the larger, more conspicuous spools of aluminum cable can also be a target simply due to visibility. Copper’s compactness aids in storage efficiency on job sites and in warehouses.

When Might Aluminum Be Considered?

It’s important to acknowledge scenarios where aluminum PV wire might hold some appeal. Its primary advantages are its lighter weight and lower material cost per meter. For exceptionally long, straight cable runs with minimal bends (where conduit size isn’t a major constraint), the weight savings of aluminum can potentially ease handling. In very specific, large-scale installations meticulously engineered for aluminum use, factoring in all infrastructure and labor, the total “installed cost per amp” mightbe competitive with copper. However, achieving this requires careful planning and often negates the benefits for most standard or expandable solar projects.

Conclusion: Copper Often Delivers Superior Value

Ultimately, the choice between aluminum and copper PV wire rests on a comprehensive evaluation of the specific project requirements, budget constraints, and long-term goals. Design engineers will weigh these factors meticulously. However, when considering the totality of factors – including ampacity efficiency, space savings, installation labor costs, material compatibility (especially grounding), supply chain reliability, and the potential for future system expansion – copper-core PV wire consistently emerges as the preferred solution for most photovoltaic installations. Its higher initial conductor cost is frequently justified by lower overall project costs, enhanced performance, easier installation, and greater long-term reliability and flexibility.

For reliable, high-performance PV wire solutions, trust JZD Cable. Contact us today to discuss your solar project needs.