When selecting electrical cables for your projects, the choice between copper and aluminum conductors is one of the most critical decisions you’ll face. XHHW-2 cable, with its cross-linked polyethylene (XLPE) insulation, represents a premium wiring solution that’s available in both conductor types. Understanding the differences between copper and aluminum XHHW-2 isn’t just about cost—it’s about performance, safety, and long-term reliability. Whether you’re working on commercial buildings, industrial facilities, or renewable energy installations, making the right choice can impact your project’s success for decades to come. This guide will provide you with a detailed comparison to inform your decision-making process.

What Is XHHW-2 Cable?

XHHW-2 stands for “Cross-Linked Polyethylene High Heat-Resistant Water-Resistant,” with the “-2” designation indicating its suitability for both wet and dry locations at temperatures up to 90°C (194°F) . This cable type features XLPE insulation, which offers superior thermal stability, chemical resistance, and longevity compared to traditional PVC-insulated wires .

The exceptional properties of XLPE insulation make XHHW-2 cable ideal for use in conduits, cable trays, and direct burial applications across residential, commercial, and industrial settings . With voltage ratings typically ranging from 600V to 1000V, XHHW-2 provides versatile solutions for various electrical distribution needs while meeting stringent safety standards including UL 44 and NEC requirements .

Copper vs Aluminum XHHW-2: Key Differences Explained

The conductor material significantly influences the performance, installation requirements, and cost of your electrical system. Here’s a detailed comparison:

Electrical Performance

Copper boasts approximately 61% higher conductivity than aluminum, which means for a given cross-sectional area, copper can carry more current with less resistance . This superior conductivity translates to lower energy losses and reduced voltage drop, especially critical in long-distance runs or high-current applications .

To achieve equivalent current-carrying capacity, aluminum conductors typically need to be two AWG sizes larger than their copper counterparts . For example, where an 8 AWG copper XHHW-2 carries approximately 50A at 75°C, an aluminum equivalent would require 6 AWG to safely handle the same current .

Physical and Mechanical Properties

Table: Comparison of Copper and Aluminum XHHW-2 Properties

|

Property

|

Copper XHHW-2

|

Aluminum XHHW-2

|

|---|---|---|

|

Conductivity

|

100% IACS (benchmark)

|

Approximately 61% of copper’s conductivity

|

|

Weight

|

Heavier (density ~8.96 g/cm³)

|

Lighter (density ~2.70 g/cm³) – about 50% lighter for equivalent conductivity

|

|

Tensile Strength

|

Higher

|

Lower, but improved with AA-8000 series alloys

|

|

Thermal Expansion

|

Lower expansion/contraction

|

Expands and contracts about 35% more than copper

|

|

Creep Resistance

|

Excellent

|

Good with modern AA-8000 series alloys

|

Aluminum’s lighter weight provides significant advantages in large-scale installations, reducing structural support requirements and easing handling . However, copper offers superior mechanical strength and flexibility, making it more forgiving during installation and more resistant to damage from vibration or bending .

Connection and Termination Considerations

Connection reliability represents one of the most critical differentiators between these conductor materials. Copper forms a soft, conductive oxide that doesn’t significantly impair connection integrity, while aluminum develops a hard, non-conductive oxide layer that can increase resistance and generate heat at termination points .

Modern aluminum installations require specialized practices including anti-oxidant paste, connectors rated specifically for aluminum (marked AL/Cu or AL7CU), and precise torque application to ensure long-term reliability . Copper terminations are generally more straightforward and forgiving of minor installation variations.

Cost Analysis

Aluminum XHHW-2 offers significant upfront cost savings, with material costs typically 40-60% lower than copper equivalents . This makes aluminum particularly attractive for large-scale projects where conductor costs represent a substantial portion of the budget.

However, a comprehensive cost assessment should consider total project expenses, including potentially larger conduits for aluminum (due to larger conductor sizes), specialized installation requirements, and long-term energy efficiency. Copper’s superior conductivity may result in lower energy losses over the system’s lifetime, offsetting some of the initial price difference .

Application Guide: Choosing the Right XHHW-2 for Your Project

When to Choose Copper XHHW-2

- Safety-Critical Applications: For emergency systems, fire pumps, hospitals, and data centers where reliability is paramount, copper’s proven track record and stable connections make it the preferred choice .

- Space-Constrained Installations: When conduit space is limited, copper’s smaller size for equivalent ampacity provides significant advantages .

- High-Vibration Environments: Copper’s superior flexibility and fatigue resistance make it ideal for industrial settings with machinery vibration or applications requiring frequent movement .

- Long-Distance Runs: Copper’s lower voltage drop characteristics make it preferable for extended circuits where voltage stability is critical .

When Aluminum XHHW-2 Is Advantageous

- Large-Scale Power Distribution: For service entrances, feeders, and utility applications where conductors are large and cost savings are substantial, aluminum offers excellent value .

- Weight-Sensitive Applications: In elevated installations, cable trays, or projects where reducing structural load is beneficial, aluminum’s light weight provides distinct advantages .

- Budget-Constrained Projects: When initial cost is a primary concern and proper installation practices can be ensured, aluminum delivers reliable performance at a lower price point .

- Fixed Installations with Professional Installation: For stable, fixed runs where experienced installers follow proper termination procedures, aluminum XHHW-2 provides dependable service .

Why Choose Our XHHW-2 Solutions?

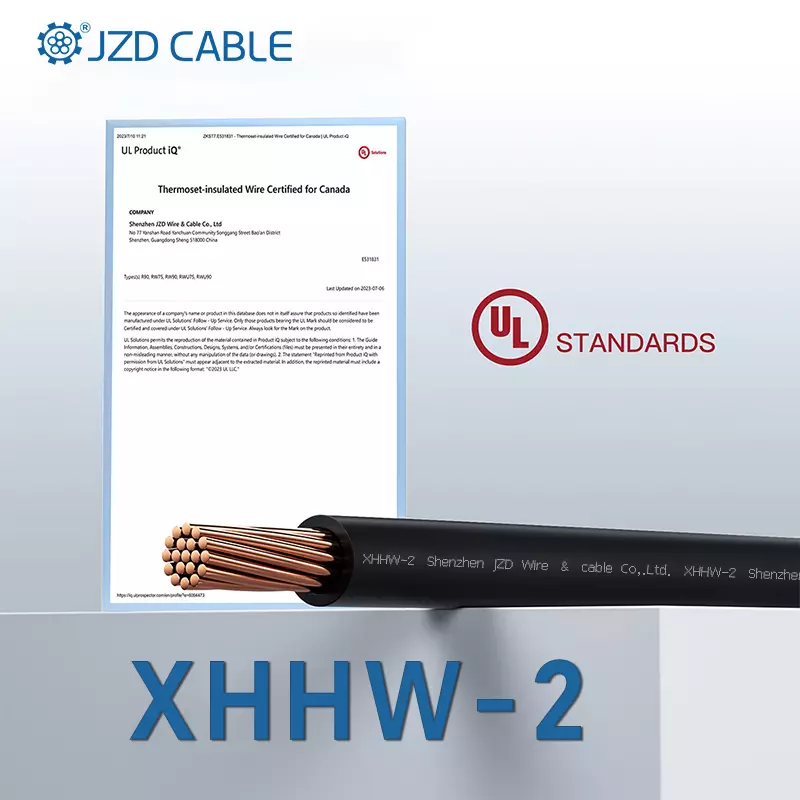

At JZD Cable, we manufacture both copper and aluminum XHHW-2 cables to the highest industry standards. Our products undergo rigorous testing and hold multiple certifications including UL 44, UL 83, and compliance with NEC, CSA, and RoHS requirements .

We offer comprehensive technical support to help you select the optimal cable solution for your specific application. Whether you require copper for maximum performance or aluminum for cost-effective power distribution, our XHHW-2 options deliver:

- Exceptional durability with XLPE insulation resistant to moisture, chemicals, and abrasion

- Temperature resilience for reliable operation in diverse environments

- Precision engineering ensuring consistent performance and safety

- Competitive pricing without compromising on quality or reliability

Conclusion

The choice between copper and aluminum XHHW-2 cables depends on your specific project requirements, budget constraints, and performance expectations. Copper remains the premium choice for maximum reliability, efficiency, and space efficiency, while aluminum offers compelling advantages for large-scale, budget-conscious, and weight-sensitive applications.

By understanding the distinct characteristics of each option and following appropriate installation practices, you can select the optimal XHHW-2 solution for your electrical system’s long-term success.

Contact us today to discuss your specific project needs and receive personalized recommendations for your XHHW-2 cable requirements.