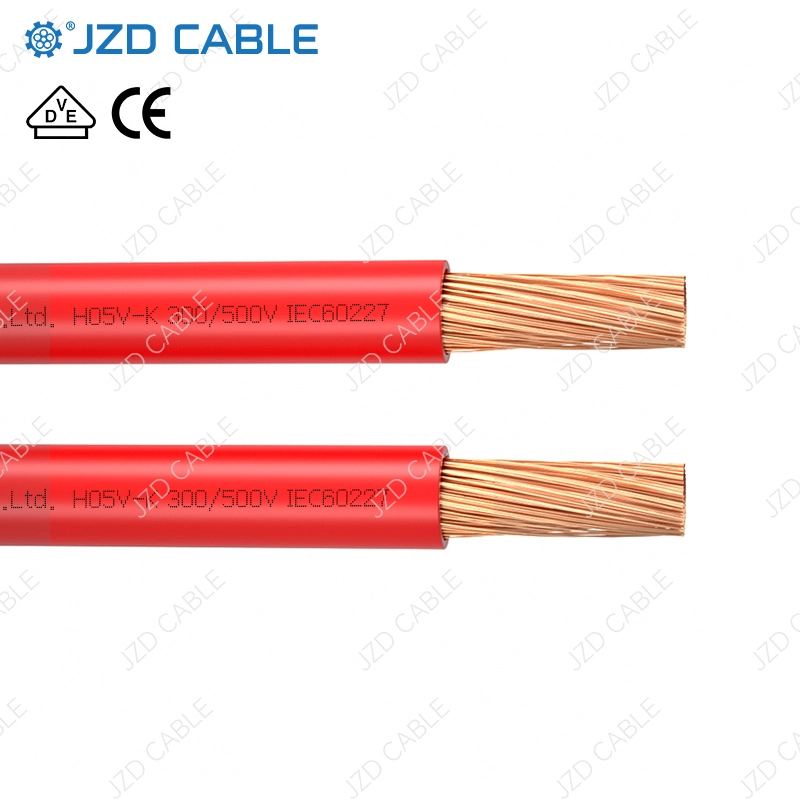

What is H05V-K/H07V-K Cable?

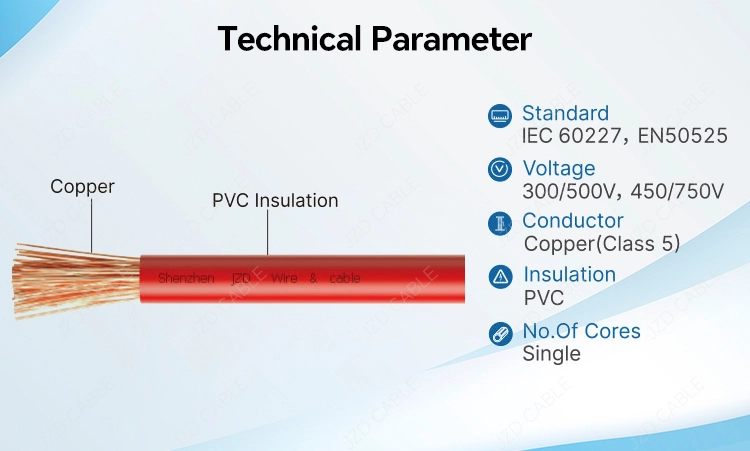

- Conductor: Stranded (Class 5) tinned copper wire, compliant with VDE 0295, IEC 60228.

- Insulation: PVC (Polyvinyl Chloride), customized colors available per customer requirements.

- Rated Voltage:

- H05V-K: 300/500V

- H07V-K: 450/750V

- Temperature Range:

- Mobile Installation: -5°C to +70°C

- Fixed Installation: -30°C to +70°C

Key Features:

1. Compliance with European Standards

- VDE-certified, ensuring alignment with European safety and environmental requirements.

2. Eco-Friendly and Safe

- Compliant with RoHS directives, using environmentally friendly materials.

- Flame-retardant and flame-resistant properties meet IEC 60332-1/HD 405.2 standards.

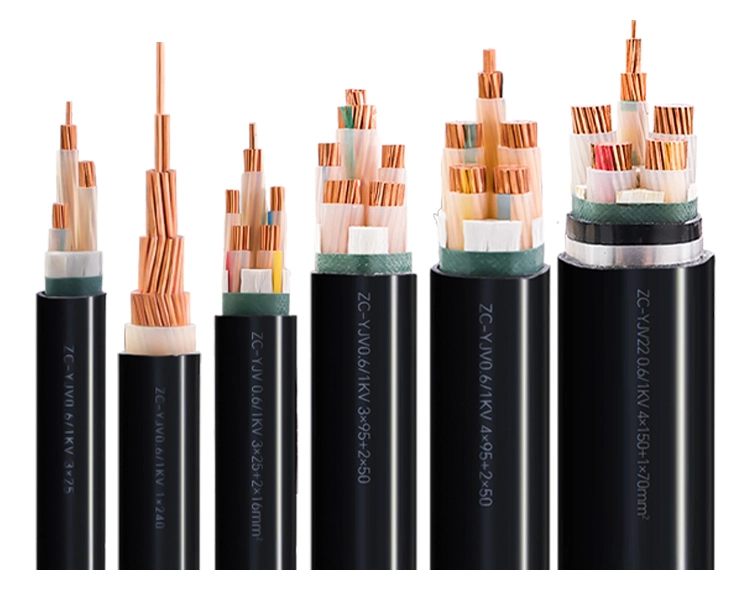

3. Versatile Application Scenarios

- Suitable for electrical cabinets, control rooms, connector internal wiring, industrial machinery, and more.

- Ideal for high-reliability industrial environments requiring flexibility and safety.

Typical Applications:

- Used in electrical cabinets, control rooms, industrial machinery, power stations, heating, and air conditioning systems.

2. Building and Lighting Systems

- Fixed or non-continuous mobile lighting systems, signaling systems, and embedded conduit installations.

3. Special Environments

- Internal wiring in equipment requiring frequent bending or limited space.

- Suitable for industrial scenarios with fire or explosion-proof requirements.

Common Mistakes in Cable Selection:

-

Incorrect Conductor Size or Voltage Rating Undersized cables can overheat, leading to voltage drops or safety hazards.

-

Improper Installation Excessive bending or compression may damage insulation, causing short circuits.

-

Ignoring Environmental Conditions Factors like temperature, chemical exposure, and mechanical stress must be considered.

-

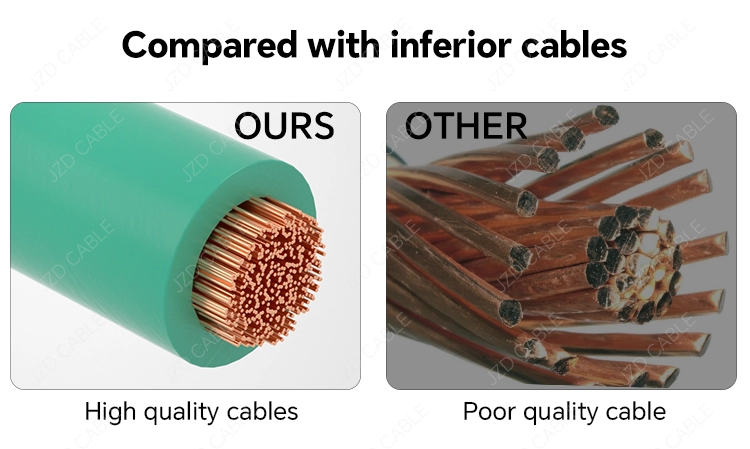

Using Low-Quality Cables Cheap cables may save costs initially but result in frequent failures and higher long-term expenses.

-

Overlooking Certifications Ensure compliance with UL, CE, or TUV standards to avoid regulatory issues.

How to Avoid These Mistakes:

-

Evaluate environmental conditions, mechanical demands, and electrical requirements. -

Verify certification compliance and ensure cables meet project-specific parameters.