What is Orange Circular Cable?

Features of Orange Circular Cable

- Smaller Footprint: Traditional power cables often appear above ground, creating a messy “spider web” that affects aesthetics and daily life. In contrast, orange circular cables are mostly buried underground, effectively saving space and enhancing visual appeal.

- High Power Supply Reliability: The performance of these cables continues to improve, particularly in reliability. They can operate in harsh environments while ensuring stable energy transmission, making them highly sought after in the market.

- Reduced Risk of Electric Shock: When installed underground, cable lines only cause trip-offs in case of faults, without harming people or animals, ensuring safety.

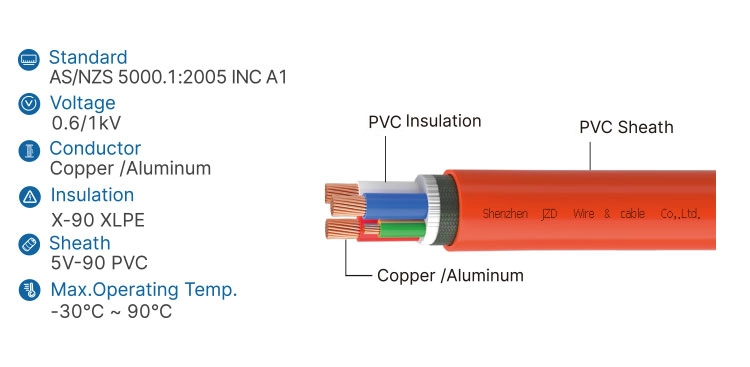

- Larger Distributed Capacitance: The conductive cores are made of highly conductive materials, and multiple cores are typically included. Compared to overhead lines of the same cross-section, orange circular cables have a higher capacitance per unit length.

- Low Maintenance Requirements: Underground cable lines require only periodic surface inspections to prevent external damage and preventive testing every 2–3 years (except for oil-filled cables), reducing maintenance efforts.

- Minimized Electrocution Risk: The conductive cores are wrapped in insulation, shielding, and protective layers. This multi-layer protection, combined with installation methods, slows down aging and reduces the likelihood of damage, thereby lowering the risk of electric shock.

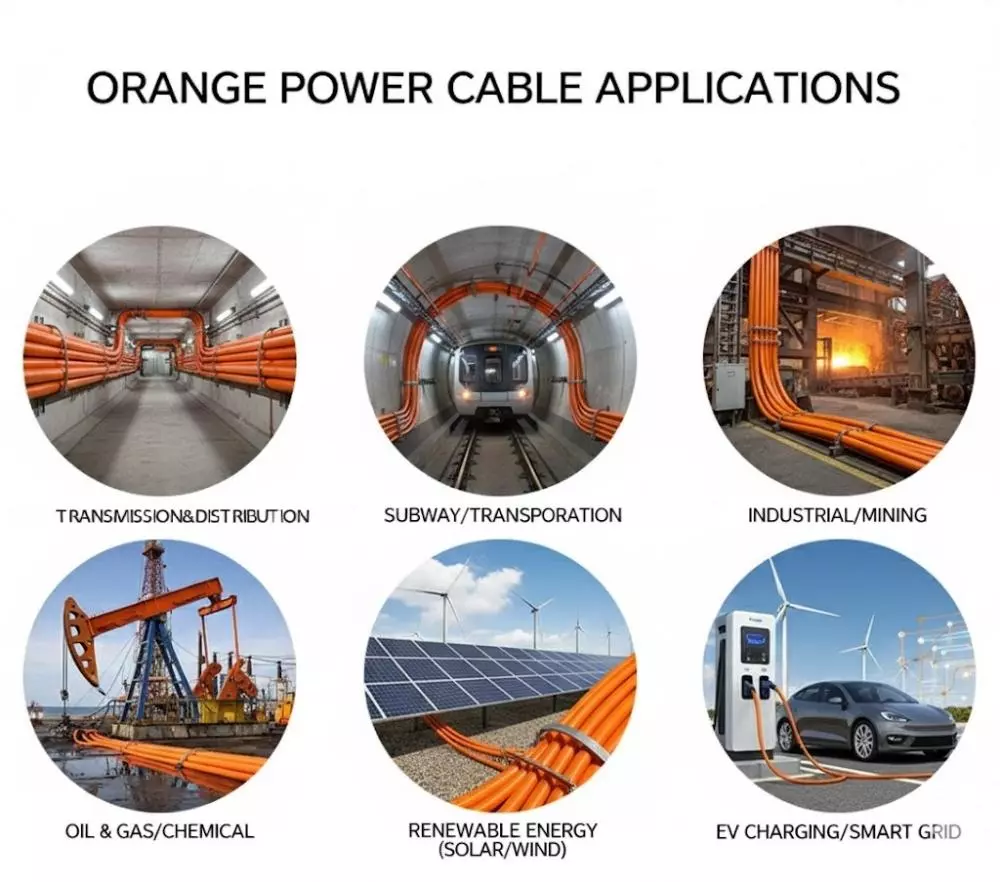

Applications:

- Core Power Systems: Transmission and distribution: High-voltage cables (rated voltage >35kV) are used for long-distance transmission, while medium and low-voltage cables (e.g., 1kV/10kV) serve urban grids and industrial power distribution. Building power systems: Low-voltage cables are applied in homes, commercial buildings, and public facilities for elevators, security systems, etc.

- Industrial and Special Scenarios: Industrial production: In factories, mines, metallurgy, and chemical plants, these cables withstand high temperatures, pressure, and corrosion, such as heavy-duty cables for metallurgical plants or explosion-proof cables for chemical enterprises. Transportation: Subways, railways, and tram systems rely on these cables for power supply, signal transmission, and overhead lines.

- Emerging Technology Applications: New energy vehicles: Cables for charging piles must meet fast-charging and safety requirements. Smart grids: Integration with communication technologies enables intelligent monitoring and management.

- Other Fields: Agriculture: Used in irrigation systems and greenhouse power supply. Energy and renewables: Connecting wind and solar power generation equipment to the grid for clean energy integration.

Common Mistakes in Cable Selection and How to Avoid Them

- Selecting the wrong cable can lead to project failures. Common errors include:

- Incorrect conductor size or voltage rating: Cables must be sized to handle the load. Undersized cables can overheat, causing voltage drops or exceeding specifications, increasing costs unnecessarily.

- Improper installation: Cables should be installed according to environmental conditions and standards. Over-bending or compression can damage insulation, leading to short circuits.

- Ignoring environmental factors: Choose cables based on operating conditions. Neglecting temperature, chemical exposure, or mechanical stress can cause premature aging or safety hazards.

- Using low-quality cables: While cheaper initially, poor-quality cables may lead to wear, damage, short circuits, or failure.

- Overlooking certifications (e.g., UL, CE, SAA): This can result in non-compliance or safety risks.

To avoid these pitfalls:

- Assess environmental conditions, mechanical needs, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.