Selecting the correct wire type is critical for the safety, performance, and code compliance of any electrical installation. Two common types, MTW and THHN, are often used in industrial and commercial settings but serve distinct purposes. A fundamental difference lies in their construction: MTW cable typically does not have an overall nylon jacket, whereas THHN cable does. This guide from JZD Cable will provide a detailed comparison to help you understand when and why to use each type.

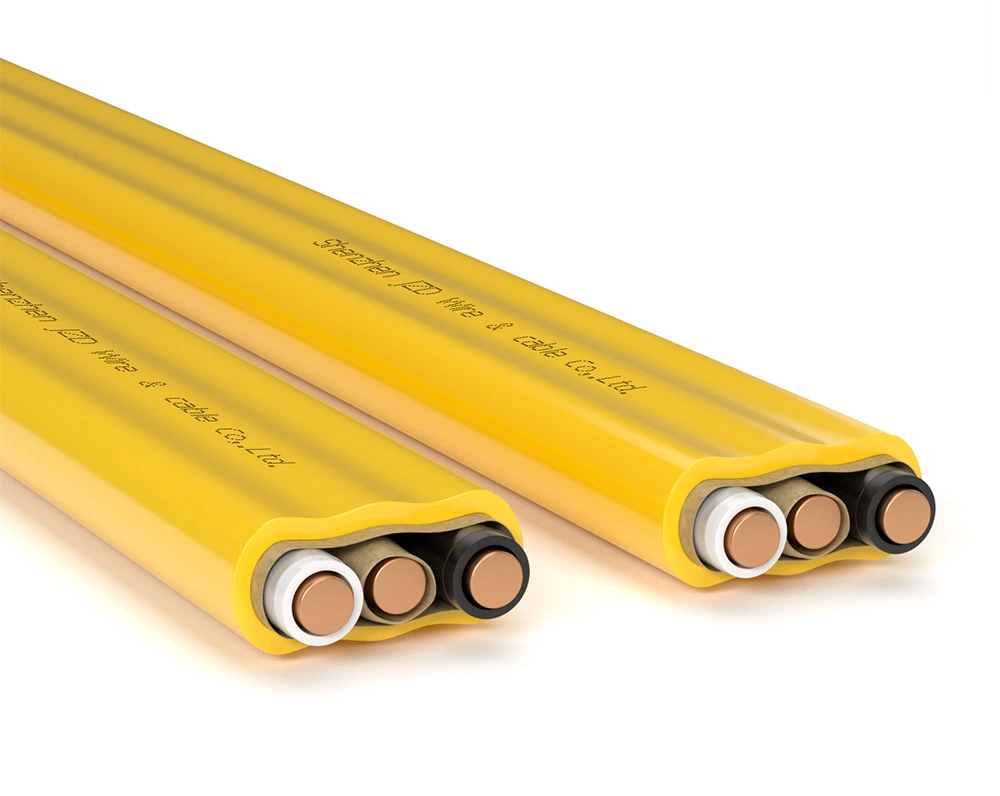

What is MTW Cable?

MTW stands for Machine Tool Wire. It is designed for flexibility and use in controlled environments, primarily within machinery and equipment. The insulation is typically made of PVC (Polyvinyl Chloride). A key distinguishing feature is that standard MTW lacks an overall nylon jacket, which contributes to its superior flexibility. It is rated for 600 volts, with a common temperature rating of 60°C in wet locations and 90°C in dry locations. Its conductors are fine-stranded to withstand vibration and repeated bending.

What is MTW Cable Used For?

MTW wire is ideal for applications where flexibility is paramount and the wire is protected from external abrasion and chemicals. Its primary uses include:

- Internal wiring of industrial control panels and cabinets.

- Machine tools, automation systems, and robotic arms.

- Appliance wiring and internal hook-ups.

- Any application inside an enclosure where the wire is subject to movement or vibration.

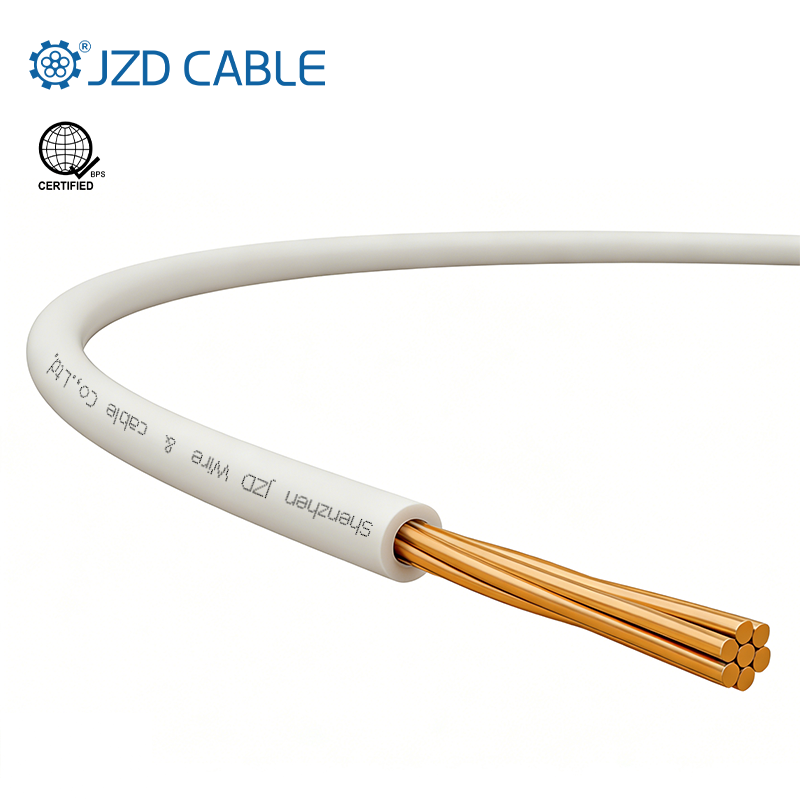

What is THHN Cable?

THHN stands for Thermoplastic High Heat-resistant Nylon-coated. This construction is key: it has PVC insulation and is covered by an extruded nylon jacket. This nylon jacket provides excellent resistance to abrasion, oil, gasoline, and moisture. THHN is a standard building wire, rated for 600 volts and 90°C in both dry and damp locations. It is available with solid or stranded conductors and is intended for fixed installation in raceways.

What is THHN Cable Used For?

THHN is the go-to wire for permanent installations within protective conduits or raceways. Its tough nylon jacket makes it suitable for harsher environments. Common applications are:

- Branch circuit and feeder wiring in residential, commercial, and industrial buildings.

- Installation in conduit for outlets, lighting, and power distribution.

- Use in dry and damp locations, such as basements or garages.

When to Use MTW vs. THHN: A Practical Guide

The choice depends on the installation environment and mechanical requirements.

|

Feature

|

MTW Cable

|

THHN Cable

|

|---|---|---|

|

Nylon Jacket

|

No (Standard MTW)

|

Yes

|

|

Primary Strength

|

High Flexibility, vibration resistance

|

Abrasion & Chemical Resistance

|

|

Conductor Stranding

|

Fine-stranded for flexibility

|

Solid or stranded (less flexible)

|

|

Ideal Environment

|

Inside protected enclosures & panels

|

Inside conduit in building structures

|

|

Best Application

|

Control wiring in machines with movement

|

Fixed power installations

|

Use MTW Cable When:

- The wire will be installed inside a control panel or machine enclosure.

- Flexibility and resistance to flexing are critical (e.g., on moving machine parts).

- The environment is controlled and protected from direct exposure to oils, chemicals, and significant abrasion.

Use THHN Cable When:

- The wire will be pulled through conduit or other raceways.

- You need protection against abrasion, moisture, oil, or solvents.

- The installation is permanent and static.

Choose the Right Wire with JZD Cable

Understanding the construction differences, like the presence of a nylon jacket, is key to selecting the right cable for safety and performance. MTW offers unmatched flexibility for internal panel wiring, while THHN provides robust protection for conduit runs.

At JZD Cable, we supply a comprehensive range of high-quality MTW and THHN that meet industry standards. Our experts can help you navigate these specifications to find the perfect solution for your project’s requirements.

Visit jzdcable.com to browse our products or contact our team for expert advice tailored to your specific needs.