Forget generic overhead wires. In Australia’s vast landscapes – from the scorching Outback to the salt-lashed coastlines and cyclone-prone tropics – getting power reliably overhead demands more than just cable. It demands engineering designed for brutal conditions and strict SAA compliance. That’s the reality we engineer into every SAA-approved aerial cable we supply at JZD Cable.

What Exactly isAerial Cable in the Aussie Context?

Think of it as the backbone stretched between poles or structures, carrying essential power safely through the open air. But here in Australia, aerial cable isn’t just insulated wire. It’s a robust system featuring:

- Weather Armor: Triple-layer UV-stabilised sheathing (typically V-90). This isn’t just weatherproof; it’s sun-baked, rain-lashed, dust-blasted proof.

- Built-in Muscle: Integrated steel messenger wire or a core designed for significant tensile strength. This combats sag over long spans and resists the constant buffet of wind – a major factor in AS/NZS 5000.2 design considerations.

- Pure Australian Compliance: Meeting SAA certification isn’t optional; it’s mandated for electrical safety (Electrical Safety Regulation 2013). It guarantees the cable withstands our unique stresses – UV degradation at extreme levels, temperature cycling from 0°C to 90°C+, and critical fire performance standards (AS/NZS 5000.1).

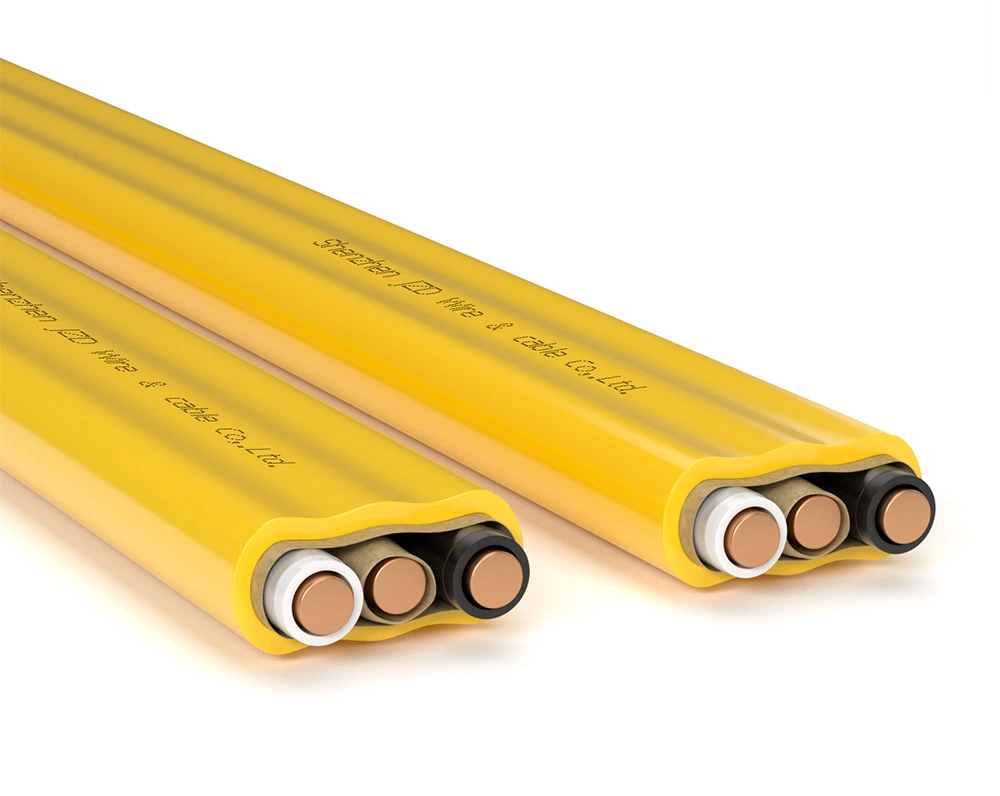

- Engineer’s Take: For most distribution, you’ll encounter either ABC (Aerial Bundled Cable) – where multiple insulated conductors are bundled together around a messenger – or Figure-8 Cable, where the conductor and messenger are co-extruded in a distinctive ‘8’ shape. ABC offers flexibility for complex routes, while Figure-8 excels in straightforward, long-span deployments, often favoured in rural rollouts.

Where JZD Cable’s SAA Aerial Solutions Earn Their Stripes: Real Applications

This isn’t theoretical. Our cables are out there, performing:

- Powering Isolated Communities: Picture dusty trucks rolling into a remote Western Australian town. The project? Extending the grid. Our heavy-duty, SAA-approved Figure-8 aluminium cables, like the JZD-F8-ACSR-70, are common workhorses here. Their low sag and high strength per weight make them ideal for stretching power reliably across kilometers of sparse terrain, connecting homesteads and small towns where underground is impractical or prohibitively expensive.

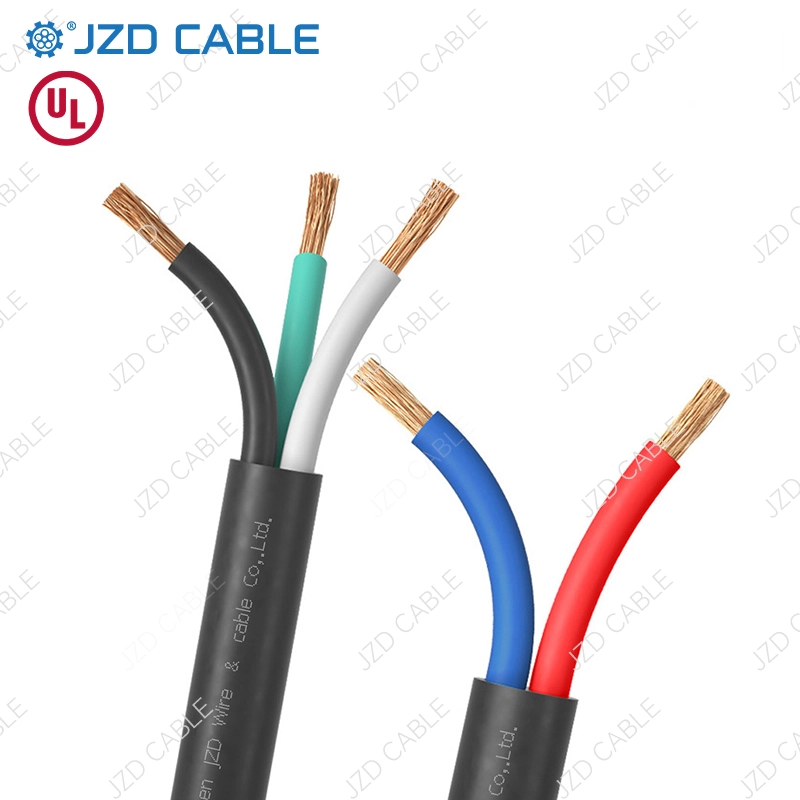

- Keeping Mines Energized & Safe: Underground copper cable costs surge in complex pit geology. Reliable overhead becomes critical. At a Queensland coal mine, our ABC cable JZD-ABC-4C16 Cu feeds critical pump stations and camps. The SAA certification is non-negotiable – it validates fire retardancy and durability crucial in flammable dust environments. The copper conductors handle starting surges from heavy equipment. Tension monitoring confirms minimal sag even with thermal cycling. It’s power you see and can trust.

- Connecting the Renewable Boom: Solar farms sprawl across sun-drenched plains. Getting that generated power outrequires robust overhead links. We supplied multi-core ABC JZD-ABC-4X240 Al for collector lines at a large-scale NSW solar installation. The aluminium construction kept project costs down significantly without compromising on the SAA-validated UV and environmental resistance needed for decades of exposure. Less downtime over the farm’s 30+ year lifespan.

- Rapid Deployment for Construction & Events: Building a new highway section in Victoria? Setting up a major regional event? Temporary power needs are real. Our lightweight, flexible ABC cables like JZD-ABC-2C10 Cu/PVC meet AS/NZS 5000.1 for temporary installations. They’re quick to deploy over poles or existing structures, easy to reel in after the job, and carry the SAA mark for on-site electrical safety compliance – one less thing for project managers to worry about.

- Supporting Telecommunications Reach: While fiber-optic often steals the data spotlight, hardened aerial cable still forms crucial backbones, especially in regional FttN (Fiber-to-the-Node) deployments, feeding cabinets dispersed across countryside.

The Copper vs. Aluminum Conductor Debate: Pragmatic Choices for Australian Projects

Let’s get practical – engineers need real-world comparisons, not just specs:

- Copper Conductor Aerial Cable:

- The Performer: King of conductivity. If you’re running heavy loads (industrial feeders, dense urban distribution requiring compact runs), copper delivers more amps in a smaller overall cable cross-section. Think feeding a large mining processing plant hub directly off a high-capacity overhead feeder.

- The Tough Guy: Naturally superior strength and corrosion resistance (critical in harsh marine or industrial zones). Less prone to issues with termination connections over the very long term.

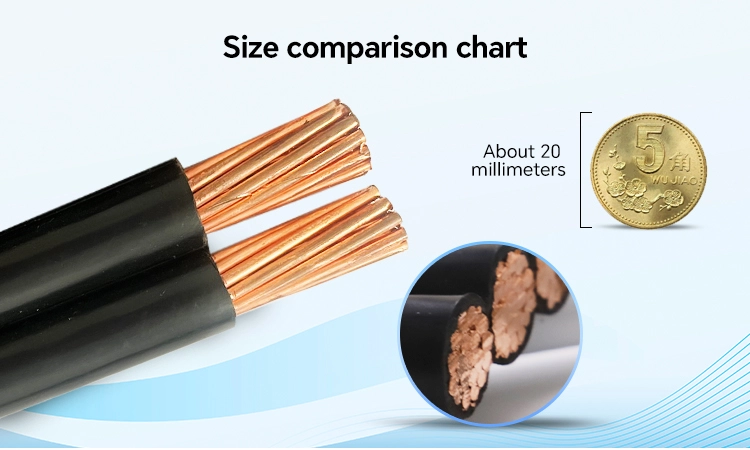

- The Trade-off: Significantly higher initial material cost and heavier weight. This increases logistics and installation strain (more supports, longer setup). In remote projects where getting heavy equipment on-site is difficult, this matters. JZD’s JZD-ABC-1CX300 Cu series excels where ultimate performance over distance trumps cost.

- Aluminum Conductor Aerial Cable:

- The Value Engine: Aluminum costs significantly less than copper. For vast rural networks, long solar farm collector runs, or projects with tight budgets, this drives huge savings. Less density means it’s lighter to haul to remote poles and easier to handle.

- The Specialist: Alloys like AAAC (All Aluminum Alloy Conductor) or the composite ACSR (Aluminum Conductor Steel Reinforced) – like our popular JZD-F8-ACSR-120/20 Figure-8 – are purpose-built. ACSR combines aluminum’s conductivity and weight benefits with the immense tensile strength of a galvanized steel core, allowing incredible spans over rugged terrain.

- The Consideration: Requires slightly larger conductor size to carry the same current as copper. Needs high-quality, anti-oxidation treated compression connections, particularly critical for achieving long-term reliability under SAA service life expectations. It’s the dominant choice (often 80%+) for Australian power distribution lines for good economic and span-distance reasons.

Why SAA Certification is Your Foundation, Not Just a Sticker

SAA approval isn’t just paperwork at JZD Cable; it’s embedded in the product DNA:

- Beyond Lab Tests: SAA compliance (with ongoing audits) means the cable isn’t just tested once; its manufacturing processis verified to consistently meet the demanding AS/NZS 5000.2 standard. Think UV accelerated aging chambers simulating decades of Outback sun.

- Real Safety: It validates the critical 90°C continuous operating temperature rating and stringent flame propagation tests (AS/NZS 5000.1). When cable runs near bushland or infrastructure, this fire performance isn’t theoretical – it’s vital risk reduction.

- Lifetime Assurance: SAA certification implies rigorous quality control. Factory test reports document every batch – insulation thickness, conductor resistance, tensile strength. It’s traceability and confidence for asset managers planning 30+ year lifespans.

- The JZD Difference: We don’t just supply SAA aerial cable; we help specifyit. We understand the voltage drops over distance, the sag-tension calculations for specific spans, and the right connectors for harsh environments.

Engineered for Your Project: JZD Cable Solutions

Forget off-the-shelf guesswork. Tell us about yourchallenge:

- Site Location: Coastal? Arid Interior? Cyclone Region?

- Voltage Needs: LV (0.6/1kV) up to HV (11kV, 33kV)?

- Load Profile: Steady power? Heavy motor starts?

- Length & Terrain: Need ACSR for mountain spans? Or ABC for navigating urban corridors?

- Temporary or Permanent?

We’ll specify the optimal, SAA-certified solution from our range: ABC (Copper & Aluminum cores, V-90 insulated) or Figure-8 (Various ACSR sizes and configurations).

Why Partner with JZD Cable?

- Deep SAA Compliance: Transparent documentation for every project.

- Technical Partnership: Get our engineers on your side.

- Proven Performance: Cables tested in Australian conditions, serving real projects.

- Customizable Solutions: Lengths, terminations, packaging.

Next Step:

- Explore Specifics: View detailed specs and application notes on our SAA Aerial Cable Solutions Page.

- Discuss Your Project: Chat directly with our engineering team. Let’s calculate sag, check clearances, and ensure compliance for your aerial run.