In today’s interconnected world, stable and reliable electrical connections are paramount. The UL2464 cable, a high-performance multi-conductor control cable, has become an indispensable component in electronics and industrial applications due to its exceptional flexibility, stringent safety certifications, and wide applicability. This article explores its features, applications, and key selection criteria.

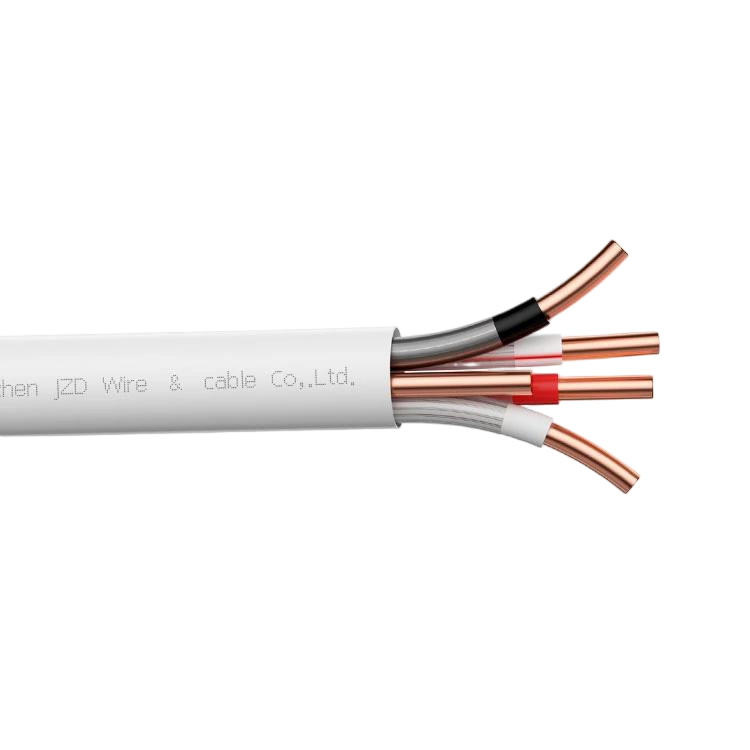

What is UL2464 Cable?

Key Features

-

Easy Installation:Highly flexible and easy to route through conduits, reducing installation time and effort. -

Safety Compliance:Passes strict flame-retardant tests and meets RoHS environmental standards. -

Ease of Processing:Uniform insulation thickness allows for effortless stripping and cutting, lowering processing costs. -

Broad Applicability:Suitable for a wide range of applications, from consumer electronics to industrial equipment.

Typical Applications

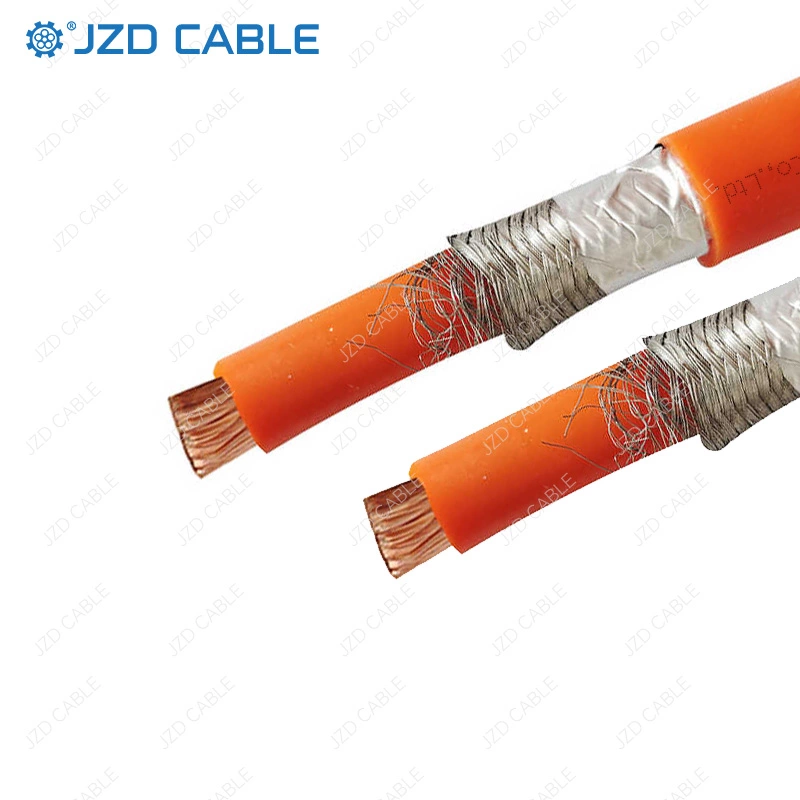

- Industrial Use:Machine tool manufacturing, power station installations, HVAC systems, and wiring for wind turbine jumpers or control panels.

- Electronics & Devices:LED lighting, computer peripherals (monitors, servers), test instruments, sensors, and signal transmission systems.

- Commercial & Daily Life:Indoor lighting, automotive lamps, office automation equipment, home appliances, and data processing systems.

Common Mistakes in Cable Selection and How to Avoid Them

-

Incorrect Conductor Size/Voltage Rating:Ensure the cable size matches the load to prevent overheating, voltage drops, or failures. -

Improper Installation:Avoid excessive bending or compression during installation to protect insulation and prevent short circuits. -

Ignoring Environmental Conditions:Consider temperature, chemical exposure, and mechanical stress to ensure longevity and safety. -

Using Low-Quality Cables:Compromising on quality may lead to premature wear, damage, or operational issues. -

Overlooking Certifications:Always verify UL, CE, or TUV compliance to meet regulatory and safety standards.

Pro Tips:

- Thoroughly evaluate environmental conditions, mechanical demands, and electrical requirements.

- Confirm certification compliance and ensure the cable meets project-specific parameters.