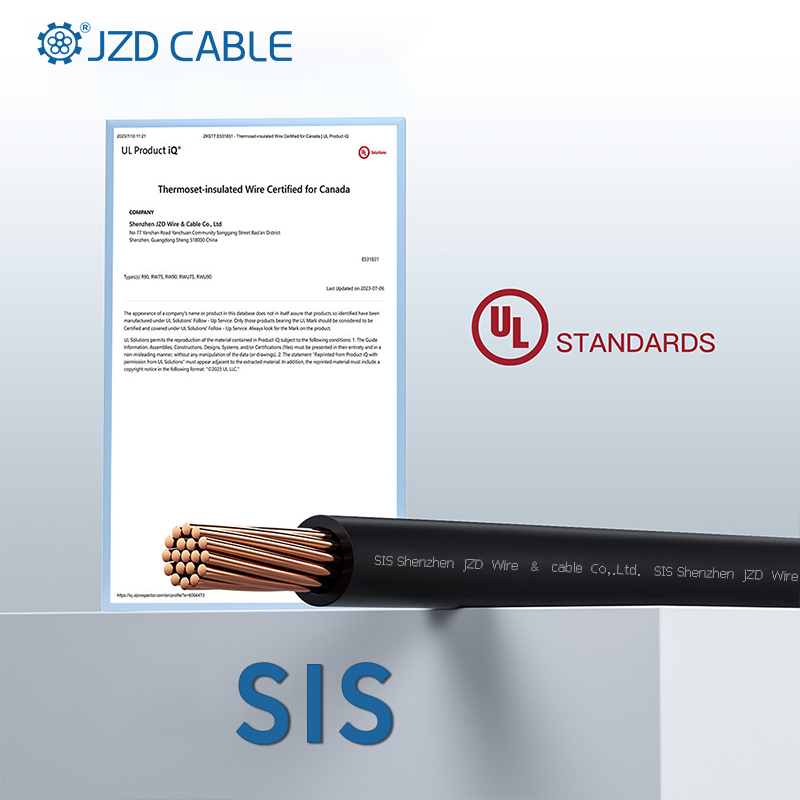

What is SIS Wire?

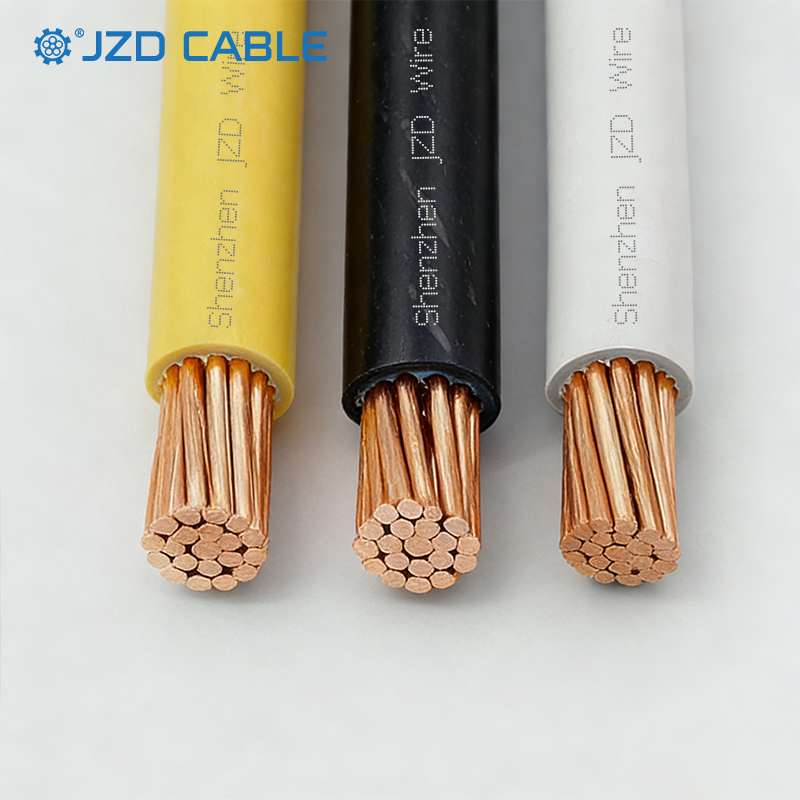

- Conductor: Stranded copper conductors for enhanced flexibility

- Insulation: Cross-linked polyethylene (XLPE) insulation

- Voltage Rating: 600 volts

- Temperature Rating: 90°C in dry locations

- Standards Compliance: UL 44 standard with VW-1 flame test certification

- Primary Characteristic: Optimized for switchboard and panelboard applications

What is SIS Cable Used For?

- Industrial switchboards and panelboards

- Control panels and motor control centers (MCCs)

- Instrumentation and automation systems

- Electrical equipment internal wiring

- Important Note: Suitable for dry locations only, within protective enclosures

What is RHW-2 Wire?

- Conductor: Copper or aluminum conductors

- Insulation: Thermoset polymer insulation (typically XLPE or EPR)

- Voltage Rating: 600 volts

- Temperature Rating: 90°C in both dry and wet locations

- Standards Compliance: UL 44 and UL 83 standards

- Key Advantage: Excellent moisture and heat resistance

What is RHW-2 Wire Used For?

- Service entrance conductors

- Feeder and branch circuit wiring

- Wet locations and direct burial applications

- Conduit and cable tray installations

- Commercial and industrial power distribution

- Underground installations

Detailed Comparison: SIS vs RHW-2 Wire

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When to Choose SIS Wire vs RHW-2 Wire

- Wiring inside switchgear, panelboards, or control cabinets

- Project specifications require UL 44 compliant wire

- Maximum flexibility is needed for tight panel spaces

- Application is exclusively in dry locations

- Working with control circuits and instrumentation

- Priority is panel-friendly installation characteristics

- General building wiring is required

- Wet location rating is necessary

- Direct burial or underground installation is needed

- Cost-effectiveness is a priority

- Versatility for various installation methods is required

- Service entrance or feeder applications

Conclusion: Making the Right Choice

- SIS wire excels in its specialized role as internal wiring for electrical equipment enclosures, offering superior flexibility and performance in controlled environments.

- RHW-2 wire provides versatile, robust performance for general building wiring applications, particularly where moisture resistance or outdoor installation is required.