Navigating the world of industrial and control cables can be complex, especially when product names sound similar. Two commonly specified types that often cause confusion are TC-ER THHN/PVC Cable and TC-ER PVC Cable. While both are excellent choices for cable tray and raceway installations, understanding their key differences is crucial for optimal performance, safety, and budget. This guide from JZD Cable, your trusted wire and cable manufacturer, will break down everything you need to know.

What is TC-ER THHN/PVC Cable?

Let’s decode the name first. TC stands for Tray Cable, indicating its primary use in cable trays. ER means “Exposed Run,” certifying that the cable can be used outside of a raceway or conduit for specific distances as per the National Electrical Code (NEC). THHN/PVC describes its conductor insulation and overall jacket material.

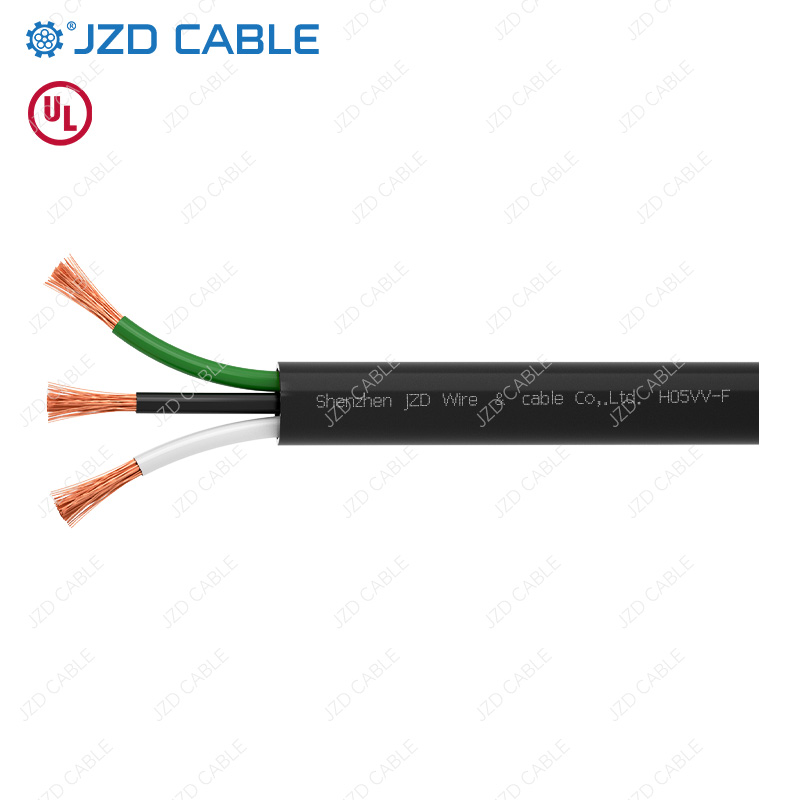

A TC-ER THHN/PVC cable is a multi-conductor cable. Each individual conductor is insulated with THHN (Thermoplastic High Heat-resistant Nylon-coated). This is a high-performance insulation known for its durability, heat resistance (typically rated up to 90°C in dry locations), and smooth surface that makes pulling easier. These insulated conductors are then bundled together under an overall PVC (Polyvinyl Chloride) jacket, which provides mechanical protection, moisture resistance, and flame retardancy for the entire cable assembly.

What is TC-ER PVC Cable?

A TC-ER PVC Cable follows the same TC-ER construction principle but with a different insulation system. In this type, each individual conductor is insulated with a standard PVC compound. This PVC insulation is robust and cost-effective but generally has a slightly lower maximum temperature rating (often 75°C or 90°C depending on the specific formulation) compared to THHN. These PVC-insulated conductors are then sheathed together under an overall PVC jacket, similar to the TC-ER THHN/PVC type.

Key Similarities Between TC-ER THHN/PVC and TC-ER PVC Cables

Despite their differences, these cables share important common ground:

- Application: Both are designed for use in industrial control circuits, instrumentation, and power-limited tray cable applications.

- Installation Method: Both are rated for use in cable trays, raceways, and exposed runs (where permitted), offering significant labor and material savings compared to conduit-only wiring.

- Jacket: Both utilize an overall PVC jacket, providing excellent resistance to oil, chemicals, moisture, and sunlight (when rated sunlight-resistant).

- Standards: Both types are typically manufactured to meet or exceed relevant standards like UL 1277 for safety and performance.

- Construction: Both are available in multi-conductor configurations (e.g., 2 to 30+ conductors) with or without a grounding conductor.

Key Differences Between TC-ER THHN/PVC and TC-ER PVC Cables

The core difference lies in the conductor insulation, which leads to several practical implications. Here is a comparative table for clarity:

|

Feature

|

TC-ER THHN/PVC Cable

|

TC-ER PVC Cable

|

|---|---|---|

|

Conductor Insulation

|

THHN (Thermoplastic High Heat-resistant Nylon-coated)

|

Standard PVC Compound

|

|

Primary Advantage

|

Higher heat rating, superior mechanical toughness, smoother surface for easier pulling.

|

Generally more cost-effective per foot.

|

|

Temperature Rating

|

Typically rated for 90°C in dry locations, 75°C in wet locations.

|

Commonly rated for 75°C or 90°C, depending on specific formulation. Always check the cable’s markings.

|

|

Durability & Pulling

|

The nylon coating over the thermoplastic provides excellent abrasion resistance and a slick surface, reducing friction during installation.

|

Good durability, but may have slightly higher friction compared to nylon-coated THHN.

|

|

Typical Cost

|

Higher, due to the more advanced insulation material and process.

|

Lower, making it a budget-friendly choice for many applications.

|

|

Best For

|

Harsher industrial environments, high-temperature areas, or long/complex pulls where reduced friction is critical.

|

General industrial control panels, HVAC systems, and applications where high-temperature performance is not the primary concern and cost is a factor.

|

How to Choose the Right Cable for Your Project

Selecting between these two excellent cables depends on your specific project requirements:

Choose TC-ER THHN/PVC Cable if:

- Your installation environment has higher ambient temperatures.

- You have long cable runs or conduit pulls with many bends where reduced friction is a major advantage.

- The application demands the highest level of mechanical toughness and abrasion resistance at the individual conductor level.

- Your project specs or local codes specifically call for THHN-insulated conductors in tray cable.

Choose TC-ER PVC Cable if:

- Cost-effectiveness is a primary driver for the project.

- The operating temperatures are within standard ranges (e.g., below 75°C).

- The installation path is relatively straightforward.

- You need a reliable, NEC-compliant cable for general industrial control, signaling, or power-limited applications.

Always Consult: When in doubt, always refer to the specific cable’s markings, manufacturer’s data sheet, and consult with a qualified electrical engineer to ensure compliance with all applicable codes like the NEC.

Partner with JZD Cable for Your Wiring Solutions

At JZD Cable, we specialize in manufacturing high-quality industrial cables like TC-ER THHN/PVC and TC-ER PVC cables. We understand that the right cable is the backbone of any reliable system.

Whether your project demands the superior pullability and temperature rating of our THHN/PVC construction or the cost-efficient reliability of our standard PVC-insulated tray cables, we provide products that meet strict standards and deliver consistent performance.

Visit our website at jzdcable.comto explore our full range of tray cables and industrial wiring solutions. Contact our expert team today for a quote, detailed specifications, or technical support to ensure you select the perfect cable for your next project.