Choosing the right cable for cable tray installations is critical for safety, compliance, and performance. Among the various options, TC (Tray Cable) and TC-ER (Tray Cable, Exposed Run) are two of the most commonly specified types. While they sound similar, understanding their distinct ratings and approved uses is essential for a successful project. This guide will break down what they are, how they compare, and how to select the perfect cable for your application.

What is TC Cable?

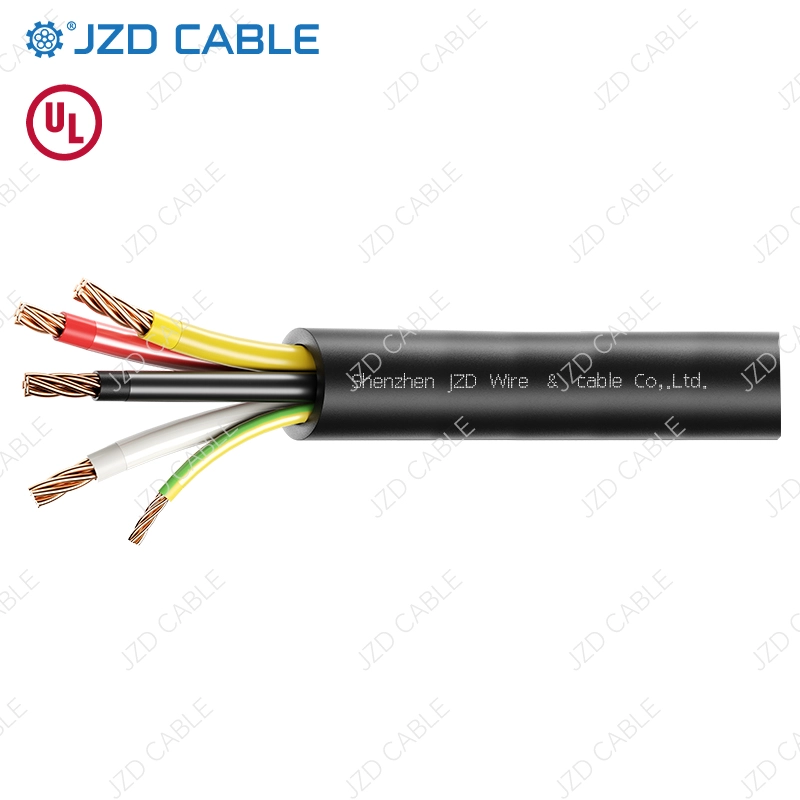

TC Cable is a versatile multi-conductor cable specifically designed for installation in cable trays. Its construction typically includes a robust overall jacket that protects the insulated conductors within. The key authorization for standard TC Cable is its listing for use in cable trays only. It is not permitted for unsupported runs between a cable tray and the equipment it serves unless specifically supported or protected as per the National Electrical Code (NEC). TC cables are widely used in industrial control panels, instrumentation, and automation systems within the protected environment of the tray.

What is TC-ER Cable?

TC-ER Cable builds upon the standard TC design with an enhanced level of protection. The “-ER” stands for Exposed Run. This crucial designation means that TC-ER Cable is not only listed for use in cable trays but is also permitted for unsupported, exposed runs outside of the tray for a specified distance. This allows it to drop from the tray directly to equipment like motors, drives, or control devices without the need for additional conduit or support, as defined by NEC regulations. This makes TC-ER a more flexible and often cost-effective solution for final connections.

Similarities Between TC and TC-ER Cables

Before looking at their differences, it’s important to recognize what they share:

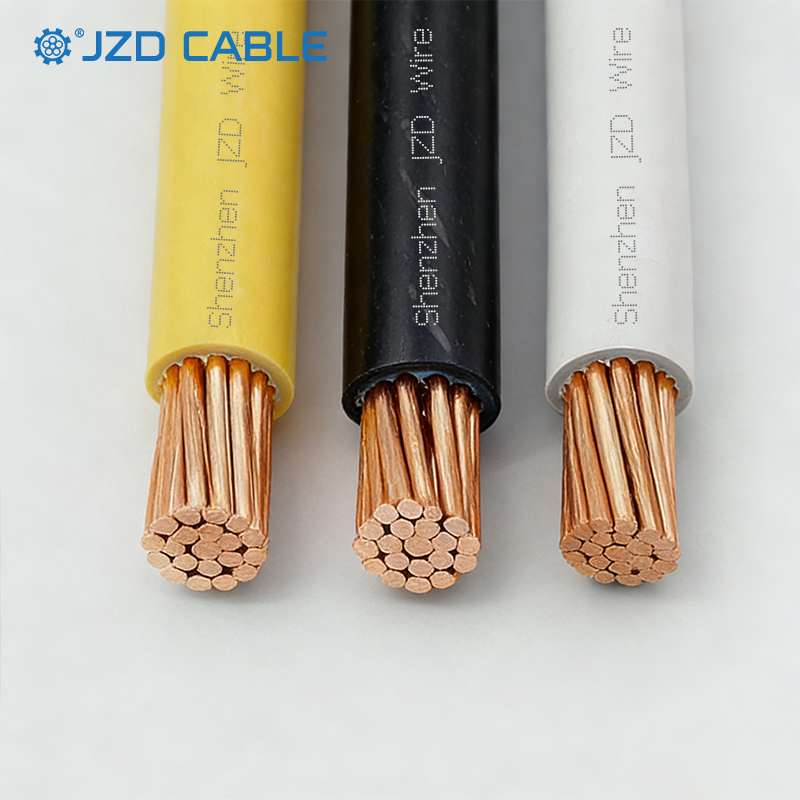

- Core Construction: Both are types of Tray Cable, featuring multiple insulated conductors (power, control, or instrumentation) under a durable overall jacket.

- Primary Use Case: Both are explicitly listed and approved for installation in cable trays.

- Standards Compliance: Both are designed and tested to meet specific UL (Underwriters Laboratories) standards for performance in industrial environments.

- Applications: Commonly used in similar settings like industrial plants, manufacturing facilities, and data centers for power, control, and signaling.

Key Differences Between TC and TC-ER Cables

The fundamental difference lies in their permitted applications outside of the cable tray. This stems from more rigorous construction requirements for TC-ER, often involving a tougher jacket and enhanced mechanical protection.

|

Feature

|

TC Cable (Tray Cable)

|

TC-ER Cable (Tray Cable, Exposed Run)

|

|---|---|---|

|

Primary Designation

|

For use in cable trays.

|

For use in cable trays and exposed runs.

|

|

Exposed Run Allowance

|

Not permitted for unsupported exposed runs outside a tray.

|

Permitted for unsupported exposed runs (up to limits defined by NEC, typically 1.8m / 6 ft).

|

|

Construction & Jacket

|

Durable jacket suitable for tray environment.

|

Typically features a more robust, sunlight-resistant, and mechanically tougher jacket.

|

|

Installation Flexibility

|

Lower. Requires conduit or support when leaving the tray.

|

Higher. Can leave the tray directly to connect to equipment, saving time and materials.

|

|

Typical Cost

|

Generally lower cost.

|

Slightly higher due to enhanced construction and testing.

|

How to Choose: TC Cable or TC-ER Cable?

Selecting the right cable depends entirely on your installation path:

- Choose Standard TC Cable if: Your entire cable run will be contained within a cable tray, ladder, or conduit. It is the ideal, cost-effective choice for backbone feeds and runs that stay solely within the tray system.

- Choose TC-ER Cable if: You need to drop cables from the tray to individual pieces of equipment (e.g., pumps, motors, control panels). Its ability to be used in exposed runs eliminates the need for extra conduit, saving significant time, labor, and material costs on the job site. When in doubt or if future flexibility is desired, specifying TC-ER provides the most options.

Pro Tip: Always consult the latest version of the National Electrical Code (NEC) and your local authority having jurisdiction (AHJ) for the most current rules governing installation distances and applications for TC-ER cables.

Your Trusted Partner for Industrial Cable Solutions

At JZD Cable, we understand the critical importance of selecting the correct cable for your industrial and commercial projects. We supply a comprehensive range of high-performance TC and TC-ER Cables designed to meet strict UL standards and NEC requirements.

Whether you need a standard TC cable for in-tray routing or the enhanced flexibility of TC-ER for equipment drops, our technical experts can help you identify the optimal, cost-effective solution. Our cables are built for durability, reliability, and compliance, ensuring your systems operate safely and efficiently.

Ready to specify the right cable? Browse our product range or contact our team today for expert guidance and competitive quotations on TC and TC-ER Cables for your next project.