THHN (Thermoplastic High Heat-Resistant Nylon-coated) cable is a staple in industrial electrical systems, particularly within power distribution cabinets and control boxes. Its unique properties make it exceptionally suited for environments where space, heat, and exposure to contaminants are concerns. This article delves into the specific applications and advantages of THHN cables in these critical settings.

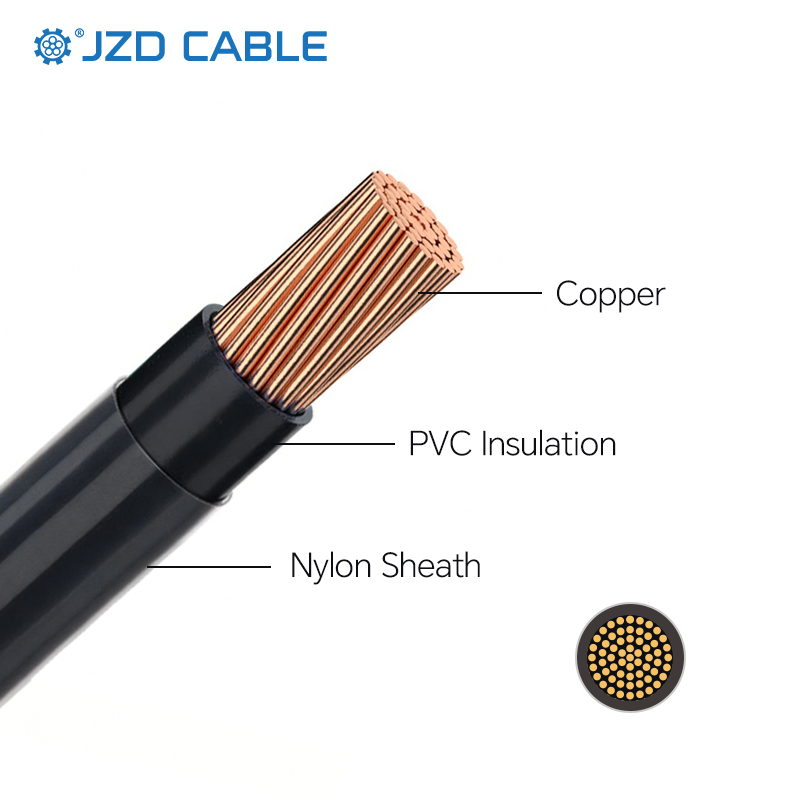

What is THHN Cable?

THHN is a single-conductor wire featuring a PVC insulation layer and a protective nylon jacket. It is designed to withstand high temperatures—up to 90°C in dry environments and 75°C in wet conditions—while offering superior resistance to oil, chemicals, and abrasion . With a voltage rating of 600V, it meets standards such as UL 83 and ANSI/NFPA 70, ensuring reliability in industrial applications .

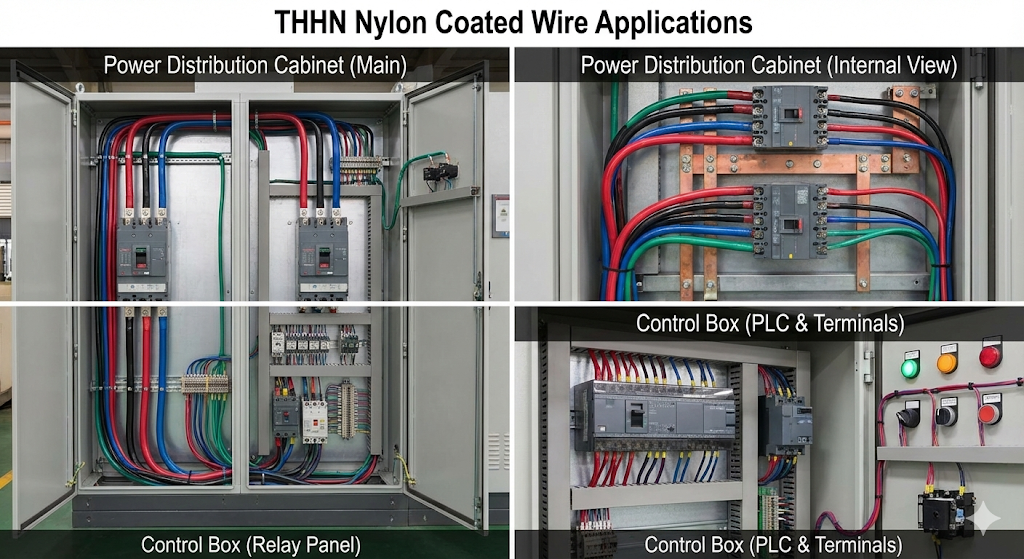

Applications in Power Distribution Cabinets

Power distribution cabinets (e.g., GGD, MNS, XL-21) manage electrical distribution and protection, housing both high-power primary circuits and low-voltage secondary circuits. THHN cables are primarily used in secondary control circuits and select primary wiring scenarios:

- Secondary Control Circuit Wiring: THHN is the go-to cable for control circuits involving breakers, interlocks, and signal feedback systems. Its 600V rating and thin insulation allow compact, multi-circuit routing within tight cable trays .

- Component Termination: Devices like relays, meters, and contactors rely on THHN for secure terminal connections. Its flexibility ensures stable, vibration-resistant terminations with cold-press connectors .

- Short-Run Primary Circuit Links: For low-current (≤32A) primary circuits, such as connections between miniature circuit breakers or fuses, THHN provides a reliable, space-saving solution .

- Internal Power Distribution: THHN efficiently routes power from sources (e.g., switch-mode power supplies) to modules and instruments inside cabinets, thanks to its small diameter and robust insulation .

Applications in Control Boxes

Control boxes (e.g., PLC panels, operator stations) demand even greater flexibility and durability due to their compact size and exposure to field conditions. THHN cables excel here in several ways:

- Full Control Circuit Wiring: From push buttons and sensors to PLC I/O modules, THHN handles entire control loops, ensuring reliable signal transmission in spaces constrained by size .

- Sensor and Module Interfacing: While standard THHN works for digital sensors, shielded variants (THHN-SL) prevent EMI in analog signals (e.g., 4–20 mA loops). The shield must be grounded at one end for optimal performance .

- Power Distribution Within Enclosures: THHN distributes AC/DC power (e.g., 24V DC to PLCs) safely inside control boxes, leveraging its heat resistance and dielectric strength .

- Localized Device Connections: For short links (≤5 m) between control boxes and nearby devices like indicator lights, THHN eliminates the need for multi-core cables, simplifying layout and maintenance .

Key Advantages of THHN Cables

THHN outperforms standard PVC cables (e.g., BV, RV) in cabinet and control box environments for several reasons:

- Heat Resistance: Rated for 90°C, THHN withstands elevated temperatures from components like contactors, reducing insulation aging in spaces where ambient temperatures can reach 60°C .

- Oil and Chemical Resistance: The nylon jacket repels oil, dust, and coolants, common in industrial settings, preventing degradation and easing cleanup .

- Mechanical Durability: Nylon’s abrasion resistance is 3–5 times higher than PVC, minimizing damage during installation or maintenance in crowded cabinets .

- Space Efficiency: Thinner insulation allows tighter bends and denser routing within cable trays, maximizing space utilization .

- Flexibility: A small bend radius (≥6× the cable diameter) simplifies manual installation and future modifications .

- Electrical Stability: Bare or tinned copper conductors ensure low contact resistance with terminals, promoting long-term reliability .

Conclusion

THHN cable’s blend of thermal stability, mechanical strength, and compact design makes it indispensable in power distribution cabinets and control boxes. By understanding its applications—from secondary circuits in power distribution cabinets to sensor wiring in control enclosures—engineers can optimize system safety and efficiency. For industrial projects requiring reliable internal wiring, THHN remains a top choice.

As a trusted provider of certified cables,JZD Cable offers THHN solutions tailored to industrial standards. Contact us for customized support.