In the world of electrical wiring, selecting the right cable type is crucial for ensuring safety, efficiency, and compliance with industry standards. Two common options that often cause confusion are THHN and TFFN cables. While they may seem similar at first glance, these wires serve distinct purposes in electrical installations. Whether you’re working on a commercial building project, industrial machinery, or lighting fixtures, understanding the differences between these cable types can significantly impact your project’s success. This guide will break down everything you need to know about THHN and TFFN cables, from their fundamental constructions to their ideal applications, helping you make informed decisions for your next electrical project .

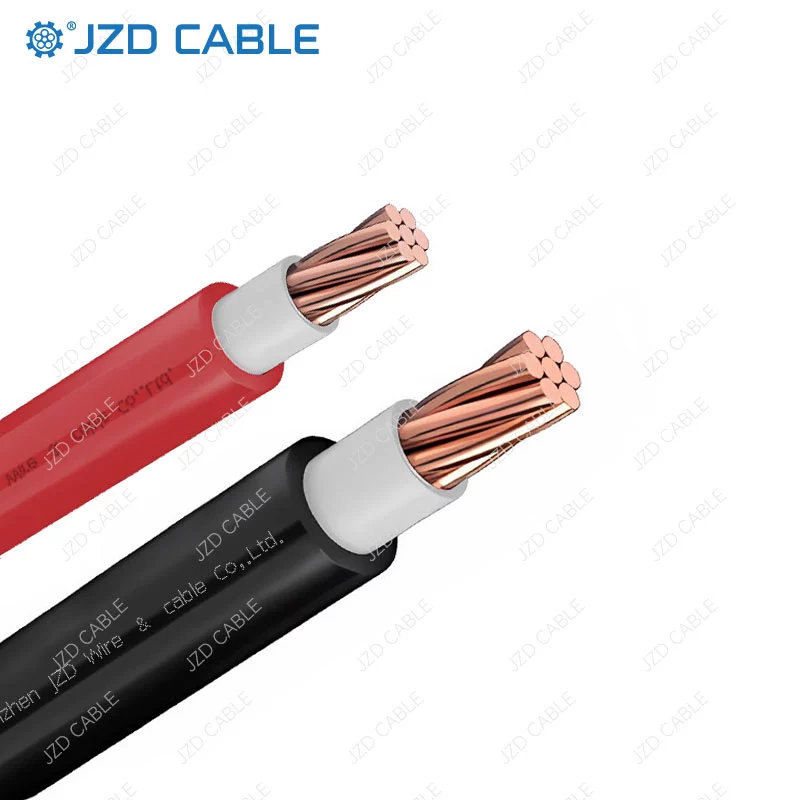

What is THHN Cable?

THHN stands for Thermoplastic High Heat-resistant Nylon-coated. This building wire is widely used in residential, commercial, and industrial applications due to its versatile properties .

The name THHN reveals its key characteristics:

- T (Thermoplastic): This refers to the PVC (Polyvinyl Chloride) insulation that provides primary electrical insulation and resistance to heat and moisture .

- HH (High Heat-resistant): Indicates the wire’s ability to withstand temperatures up to 90°C (194°F) in dry environments and 75°C (167°F) in wet locations .

- N (Nylon-coated): The outer nylon jacket offers excellent protection against abrasion, chemicals, oils, and physical damage .

THHN cables typically feature either solid or stranded copper conductors and are rated for 600 volts . They come in a wide range of sizes, from as small as 14 AWG to as large as 1000 MCM, making them suitable for various applications from branch circuits to main power supply lines . The nylon jacket not only provides durability but also reduces friction during installation, making it easier to pull through conduits .

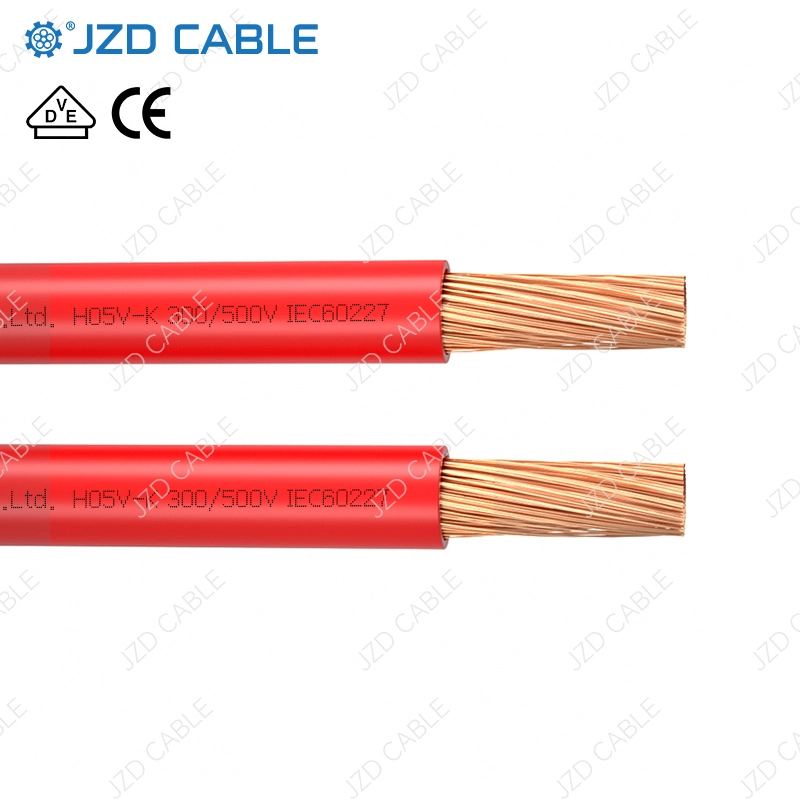

What is TFFN Cable?

TFFN means Thermoplastic Flexible Fixture Nylon, and it’s specifically designed for applications requiring greater flexibility .

Breaking down the acronym:

- T (Thermoplastic): Like THHN, TFFN uses PVC insulation as its primary insulating material .

- FF (Flexible Fixture): This indicates the wire’s design purpose—it’s more flexible and intended for fixed installation wiring within appliances and fixtures .

- N (Nylon): The thin but tough nylon outer jacket provides additional protection against abrasion, chemicals, and oils .

TFFN wire features finely stranded copper conductors that give it superior flexibility compared to THHN . It’s available in smaller AWG sizes, typically 18 and 16, with some variations including 14 AWG . TFFN is also rated for 600 volts and can withstand temperatures up to 90°C in dry environments . The combination of stranded conductors and nylon jacket makes TFFN ideal for applications requiring frequent bending or installation in tight spaces .

Key Similarities Between THHN and TFFN Cables

Despite their differences, THHN and TFFN share several important characteristics:

- Basic Construction Materials: Both wires use thermoplastic (PVC) insulation and have a nylon outer jacket, providing similar basic protection against environmental factors .

- Voltage Rating: Each cable type is typically rated for 600 volts, making them suitable for similar voltage applications .

- Temperature Rating in Dry Locations: Both wires can handle temperatures up to 90°C (194°F) in dry environments .

- Nylon Jacket Benefits: The nylon coating on both cables offers resistance to abrasion, chemicals, oils, and other hydrocarbons, extending their lifespan in demanding conditions .

- Standards Compliance: THHN and TFFN both comply with UL standards (UL 62, UL 83, UL 1581) and are recognized by the National Electrical Code (NEC) for specific applications .

- Color Coding: Both cable types are available in standard color codes for easy circuit identification, including black, red, blue, green, and others .

Differences Between THHN and TFFN Cables (With Comparison Table)

While THHN and TFFN share some similarities, their differences are significant enough to affect their suitability for specific applications. The table below summarizes these key distinctions:

|

Feature

|

THHN Cable

|

TFFN Cable

|

|---|---|---|

|

Full Form

|

Thermoplastic High Heat-resistant Nylon-coated

|

Thermoplastic Flexible Fixture Nylon

|

|

Conductor Type

|

Solid or stranded (depending on size)

|

Finely stranded for flexibility

|

|

Size Range

|

14 AWG to 1000+ MCM

|

Typically 18 AWG to 14 AWG

|

|

Flexibility

|

Moderate (less flexible, especially in larger sizes)

|

High (designed for flexibility)

|

|

Primary Applications

|

Branch circuits, main power lines, building wiring

|

Fixture wiring, appliances, control circuits

|

|

NEC Classification

|

Building wire

|

Fixture wire

|

|

Wet Location Rating

|

75°C when dual-rated as THWN

|

Not typically rated for wet locations

|

|

Bend Resistance

|

Good (approximately 50,000 bend cycles)

|

Excellent (over 1,000,000 bend cycles)

|

|

Ideal Use Cases

|

Fixed installations in walls, conduits, panels

|

Moving parts, tight spaces, frequent bending

|

Detailed Explanation of Key Differences:

- Size Range and Flexibility: The most noticeable difference lies in their size availability and flexibility. THHN comes in a much wider range of sizes, including larger diameters capable of handling higher current loads. TFFN, by contrast, is limited to smaller diameters (typically 18-16 AWG) but offers greater flexibility due to its finely stranded construction .

- NEC Classification and Applications: The National Electrical Code classifies THHN as a building wire and TFFN as a fixture wire. This distinction affects where and how each can be used. THHN is suitable for branch circuits and feeders, while TFFN is specifically designed for connecting fixtures to branch circuits .

- Wet Location Performance: While many THHN wires carry a dual rating (THHN/THWN) that makes them suitable for wet locations, TFFN is generally not recommended for wet environments. In wet conditions, TFFN’s heat resistance decreases significantly .

- Durability in Dynamic Applications: TFFN’s design allows it to withstand over 1 million bend cycles, making it far superior for applications involving movement, such as robotic arms or moving machine parts. THHN, with approximately 50,000 bend cycles, is better suited for static installations .

How to Choose Between THHN and TFFN Cables

Selecting the appropriate cable type depends on several factors specific to your project:

Choose THHN Cable When:

- You need to run branch circuits or main power lines in residential, commercial, or industrial buildings .

- The installation requires a wide range of wire sizes, especially larger diameters for higher current applications .

- The wire will be installed in conduits within walls, ceilings, or underground .

- The application involves wet or damp locations (ensure the cable is dual-rated as THWN) .

- The installation is permanent and won’t require frequent bending or movement after installation .

Choose TFFN Cable When:

- You’re working on fixture wiring for lighting systems or appliances .

- The application requires high flexibility, especially in tight spaces or with frequent bending .

- You’re working with control circuits, machine tools, or automotive applications where movement is involved .

- The project involves fixed installations within equipment or machinery that require durable, flexible wiring .

- You’re working with smaller current loads typically associated with 18-14 AWG wire sizes .

Additional Considerations:

- Always check local electrical codes and regulations before selecting wire types for specific applications .

- Consider environmental factors such as temperature extremes, exposure to chemicals or oils, and moisture levels .

- For applications requiring both flexibility and wet location rating, consider alternative options or consult with an electrical professional .

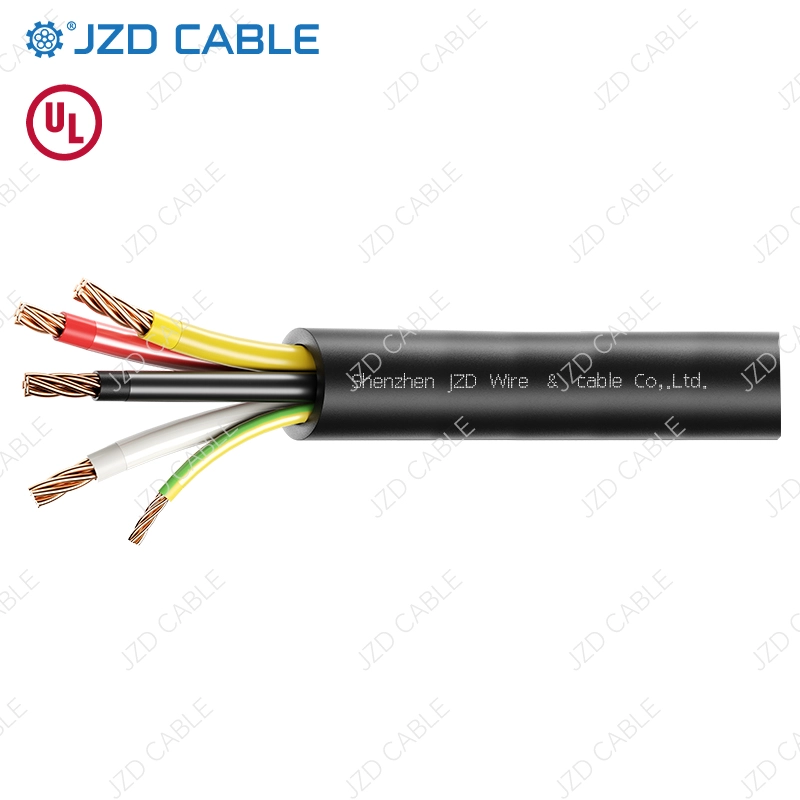

Why Choose JZD Cable?

At JZD Cable, we understand that the success of your electrical projects depends on the quality and reliability of your wiring components. As a leading provider of electrical cables, including both THHN and TFFN options, we are committed to delivering products that meet the highest industry standards.

Our THHN and TFFN cables are manufactured with precision and undergo rigorous testing to ensure:

- Consistent Performance: Every cable meets specified electrical and mechanical properties for reliable operation .

- Safety Compliance: All products adhere to relevant UL standards, NEC requirements, and RoHS directives .

- Durability: Enhanced construction techniques provide superior abrasion resistance and longevity .

We offer a comprehensive range of sizes and colors for both THHN and TFFN cables, ensuring you find the perfect solution for your specific application. Our technical support team is available to help you select the right cable type based on your project requirements, environmental conditions, and budget considerations.

Whether you’re working on a large-scale commercial installation or specialized equipment wiring, trust JZD Cable to provide the quality products and expert guidance you need. Visit our website at jzdcable.com to explore our complete product catalog and learn more about our customization options.