Navigating the complexities of industrial wiring requires cables that are both durable and compliant. TWN75 wire stands out as a premier choice for Canadian and North American markets, offering a robust combination of a thermoplastic PVC insulator and a protective nylon jacket. This article delves into what TWN75 cable is, its key features, common applications, and why it might be the ideal solution for your next project in demanding environments.

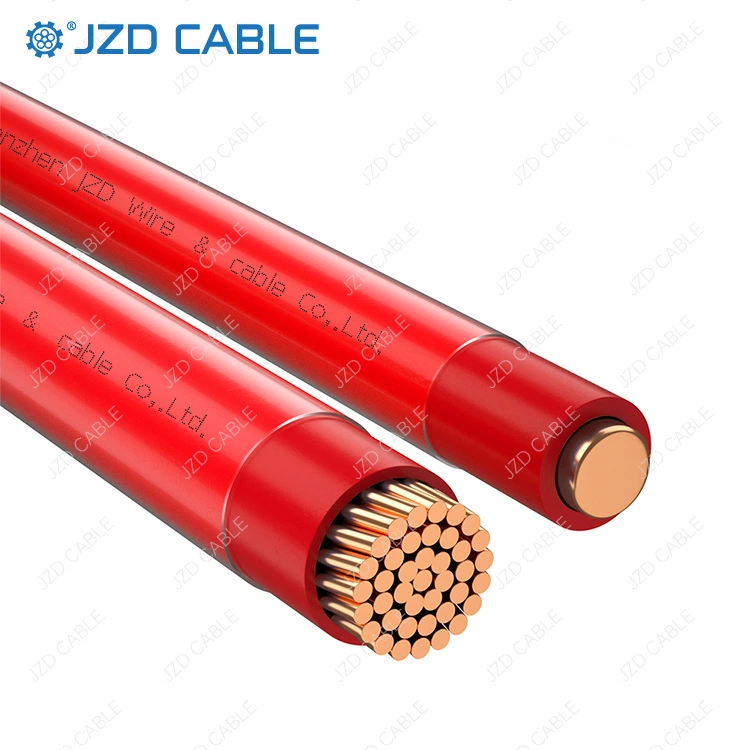

What Is TWN75 Wire?

Features and Applications of TWN75 Wire

1.Excellent Mechanical Performance

- Abrasion Resistance: High surface hardness and low friction coefficient protect against wear during installation, dragging, or laying, extending service life.

- Impact Toughness: Withstands compression, collisions, and other mechanical stresses to safeguard internal conductors and insulation.

- High Strength and Flexibility: Superior tensile and tear strength make it ideal for bending applications.

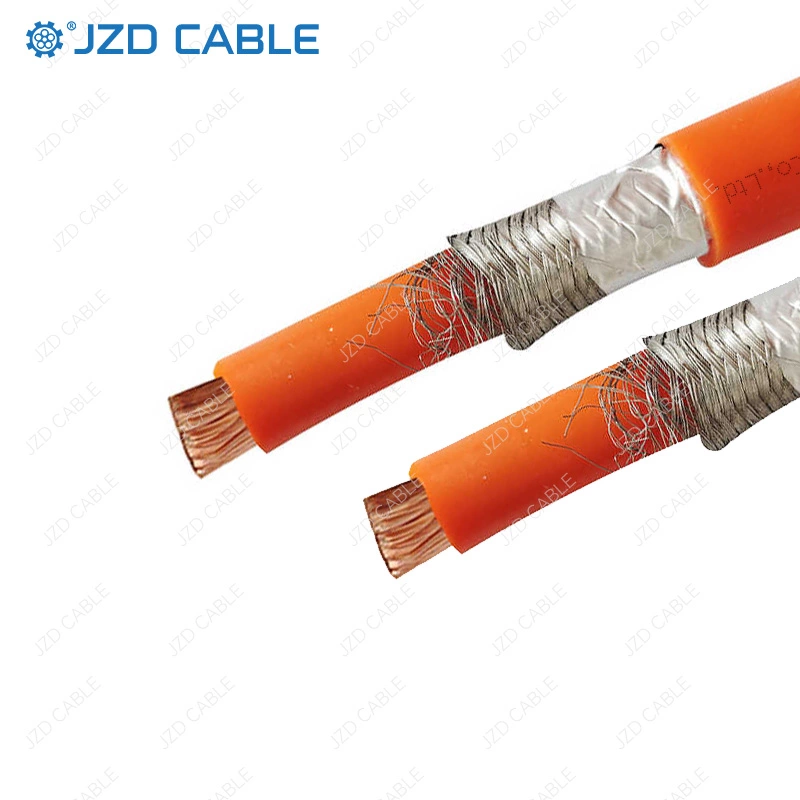

2.Strong Chemical Resistance

- Resistant to oils, fuels, solvents, detergents, and other chemicals, making it suitable for chemical plants, engineering machinery, and corrosive environments.

3.Eco-Friendly and Flame-Retardant

- Halogen-Free: Manufactured without halogen additives, producing low smoke and toxicity, compliant with RoHS standards.

- Flame Retardancy: Self-extinguishing properties meet UL VW-1 and IEC 60332 standards, ideal for construction and rail transit.

4.Physical and Processing Advantages

- Lightweight: Small diameter and low weight ease installation.

- Easy Processing: Thin-wall extrusion ensures uniform jacketing and cost efficiency.

Typical Applications

- Machine Tool and Equipment Wiring: Powers and controls lathes, milling machines, injection molding machines, and automated production lines, meeting CSA/C22.2 No. 75 standards for humid and oily workshop conditions.

- Internal Wiring for Appliances and Devices: Used as internal power cords, branch circuits, and terminal connections in dry or damp areas, common in appliances, pumps, fans, and compressors.

- Building and Industrial Control Circuits: Suitable for low-voltage control and power distribution (≤600V), installable in conduits, cable trays, and supports indoor/outdoor setups.

- Direct Burial and Outdoor Wiring: When compliant with local electrical codes, TWN75 can be used for direct burial or overhead installation (with appropriate jacketing and protection ratings).

Common Mistakes in Cable Selection

Avoid these pitfalls to ensure project success:

- Incorrect conductor size or voltage rating, leading to overheating, voltage drops, or unnecessary costs.

- Improper installation methods, such as over-bending or compression, damaging insulation and causing short circuits.

- Ignoring environmental factors like temperature, chemical exposure, and mechanical stress, which accelerate aging or pose safety risks.

- Using low-quality cables that sacrifice durability and safety for short-term savings.

- Overlooking certifications (e.g., UL, CE, TUV), risking non-compliance and hazards.

Pro Tips:

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.

By adhering to these standards, engineers can prevent performance mismatches and ensure long-term reliability.

Why Choose JZD Cable?

At JZD Cable, we specialize in manufacturing high-quality, certified cables like TWN75 that meet rigorous Canadian and international standards. Our products are engineered for durability, safety, and optimal performance in diverse applications—from industrial automation to residential wiring. Partner with us for reliable solutions backed by expertise and commitment to excellence. Explore our full range at jzdcable.com.