Navigating the complex world of industrial power cabling requires solutions that offer both performance and safety. Among the critical standards is the UL Certified TC-ER Cable (Tray Cable – Exposed Run). This designation signifies a cable engineered to meet rigorous requirements for use outside of cable trays or raceways in specific industrial environments. At JZD Cable, we understand the importance of reliable power distribution and design our UL Certified TC-ER cables to deliver exceptional performance where it matters most.

What is UL Certified TC-ER Cable?

TC-ER Cable is a specific type of Type TC (Tray Cable) defined by the National Electrical Code (NEC) and certified by Underwriters Laboratories (UL) under Standard UL 1277.

Here’s what defines it:

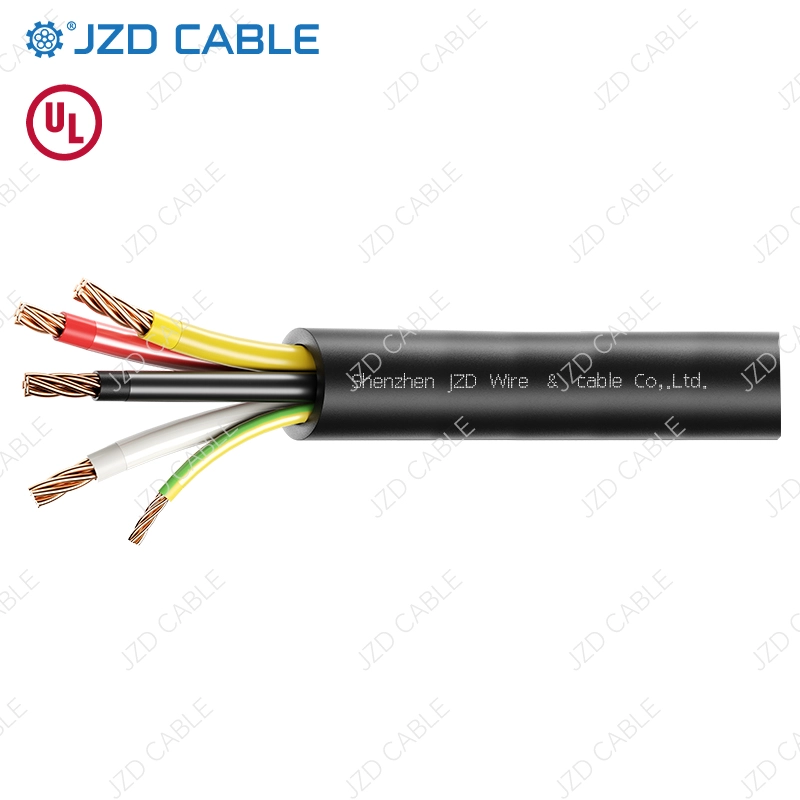

- Construction: Typically features multiple insulated conductors (usually THHN/THWN-2 or similar), often with a grounding conductor, all encased within a robust, sunlight-resistant outer jacket (commonly PVC, LSZH, or CPE). A key differentiator is the inclusion of mechanical reinforcement under the jacket, such as interlocked armor (ILA) or a layer of robust tape or braid. This reinforcement is crucial for its “Exposed Run” rating.

- The “ER” Designation (Exposed Run): This is the defining feature. Unlike standard Type TC cable, UL Certified TC-ER Cable is approved for “Exposed Runs” in industrial establishments. This means it can be installed:

- Between cable trays.

- From cable trays directly to utilization equipment (like motors, drives, panels).

- Along a supporting structure without being enclosed in conduit or a raceway for significant portions of its run. This dramatically simplifies installation in complex facilities.

- UL Certification: UL certification ensures the cable meets specific safety standards regarding construction, materials, fire resistance (including flame spread and smoke generation ratings like CMP/CMR/CM), crush resistance, impact resistance, and suitability for exposure to sunlight, oils, and industrial chemicals. The “TC-ER” designation is explicitly verified by UL testing.

- Operating Temperatures: Designed for reliable operation in demanding environments, typically rated at 90°C (194°F) for wet or dry locations.

- Core Advantages:

- Reduced Installation Costs: Eliminates the need for conduit over extended exposed runs.

- Greater Flexibility: Easier to route around equipment and obstacles than conduit-bound wiring.

- Mechanical Protection: The inherent reinforcement provides resistance to crushing, impact, and physical damage.

- Durability: Resists sunlight (UV), moisture, oils, and industrial chemicals common in manufacturing settings.

- Safety Compliance: Meets NEC requirements for power, control, and lighting circuits in industrial environments and ensures safe operation under exposed conditions.

Essential Applications for UL Certified TC-ER Cable

TC-ER cable’s unique capabilities make it indispensable in several demanding industrial settings:

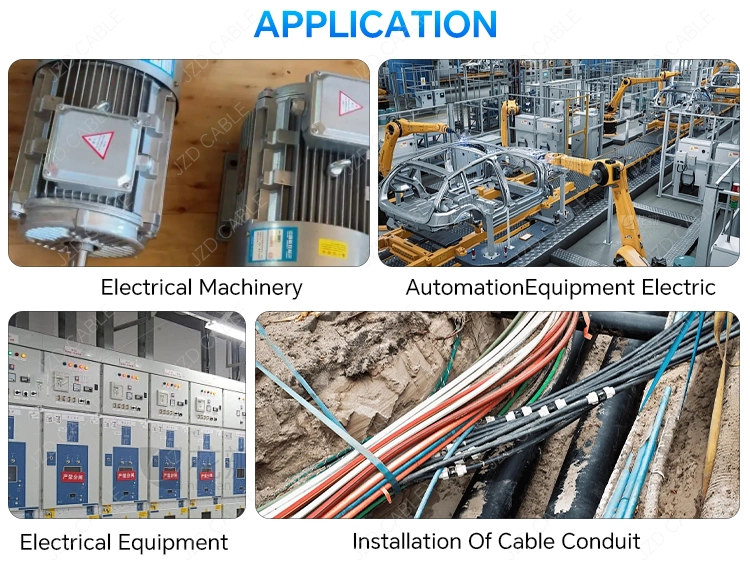

- Industrial Facilities & Manufacturing Plants:

- Running power from overhead cable trays down to individual machines (CNC machines, presses, assembly lines, robotics).

- Connecting motor control centers (MCCs) to motors.

- Distributing power to lighting circuits along production lines.

- Powering material handling equipment (conveyors, lifts).

- Providing reliable power in areas with high exposure to vibration, dust, oils, and solvents.

- Water & Wastewater Treatment Plants:

- Connecting pumps, motors, blowers, and controls.

- Ideal for areas prone to moisture, humidity, and potential chemical exposure.

- Power Generation Facilities (Thermal, Hydro, Gas Turbines):

- Auxiliary power distribution within the plant.

- Connections to control panels, fans, pumps, and instrumentation outside raceways.

- Oil & Gas Processing Facilities (Specific Safe Areas – Always verify NEC Class/Division requirements):

- Power and control wiring in non-hazardous processing areas, pump stations, and compressor stations where exposure to elements and minor physical damage is expected.

- Large Warehouses & Distribution Centers:

- Powering conveyor systems, automated storage and retrieval systems (AS/RS), and high-bay lighting from tray runs down to equipment mounted on floors or structures.

- Data Centers (Support Infrastructure):

- Powering mechanical equipment (CRAC/CRAH units, chillers, pumps) located outside the IT spaces and routed via cable trays.

- Renewable Energy Plants (Solar/Wind):

- Power collection from combiner boxes to main inverters/substations (using tray systems with exposed drops).

- Powering balance-of-plant equipment (pumps, trackers, control systems) in exposed industrial environments.

Why Choose JZD Cable’s UL Certified TC-ER Cable?

At JZD Cable, we prioritize quality and performance. Our UL Certified TC-ER cables are manufactured to exceed industry standards, ensuring:

- Genuine UL Listing: Full compliance with UL 1277 for TC and TC-ER performance.

- Robust Construction: Durable, sunlight-resistant outer jackets and proven reinforcement for reliable exposed run performance and damage resistance.

- Material Integrity: High-quality copper conductors and insulation materials for optimal electrical performance and longevity.

- Rigorous Testing: Subjected to stringent quality control tests to ensure adherence to all specifications and safety requirements.

- Application Expertise: Our team understands industrial needs and can help select the right TC-ER cable configuration for your specific project.

Ensure Reliable and Code-Compliant Power Distribution

UL Certified TC-ER Cable is a cornerstone of safe, efficient, and cost-effective power distribution in modern industrial facilities. By understanding its properties and applications, engineers and contractors can design installations that maximize reliability while minimizing installation complexity and cost.

Ready to power your industrial project with confidence?

Explore JZD Cable’s range of reliable, UL Certified TC-ER Cables designed for demanding environments.

Visit our website jzdcable.com or contact us today to discuss your specific requirements and request a quote!