Choosing between UL1007 and UL1015 wires impacts safety and performance in electrical projects. At JZD CABLE, we clarify these key differences to help engineers select the optimal solution for voltage requirements, temperature environments, and application scenarios.

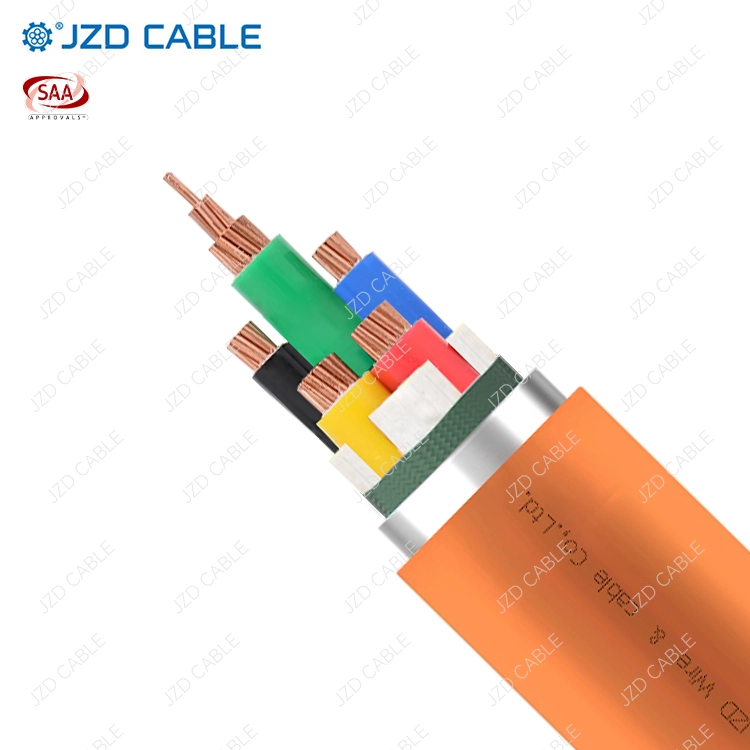

Section 1: UL1015 Wire (600V) – Heavy-Duty Applications

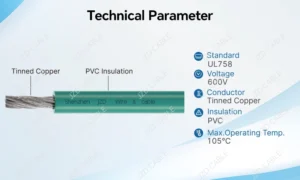

UL1015 Specifications

- Voltage Rating: 600V

- Max Temp: 105°C

- Conductor: Tinned Copper

- Insulation: PVC

- Key Properties: Acid/Alkali/Oil/Moisture/Fungal Resistant

UL1015 Applications

Used for internal wiring of control cabinets, medical technology equipment, electronic components, and control devices, as well as protective hoses and pipelines installed in mechanical engineering, used as connection wires for transformers and motors. Acid resistant, alkali resistant, oil resistant, moisture resistant, and fungal resistant.

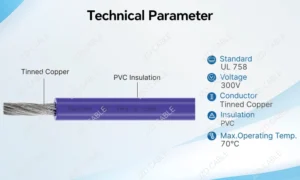

Section 2: UL1007 Wire (300V) – Electronics & Appliances

UL1007 Specifications

- Voltage Rating: 300V

- Max Temp: 70°C

- Conductor: Tinned Copper

- Insulation: PVC

- Key Properties: Oil/Moisture/Fungal resistant with solvent heat resistance

UL1007 Applications

Used for internal connection wires of various household appliances, lighting fixtures, electric heating equipment, electrical electronics, instruments and other general electronic and electrical equipment.It has certain heat resistance and can work at a temperature of 70 °C when exposed to solvents such as oil.Acid resistant, alkali resistant, oil resistant, moisture resistant, and fungal resistant.

Section 3: Side-by-Side Comparison

Key Selection Criteria

- Voltage Needs:

- UL1015 for 600V systems (industrial motors, transformers)

- UL1007 for 300V applications (appliances, electronics)

- Temperature Exposure:

- UL1015 handles 105°C environments

- UL1007 suitable for ≤70°C operations

- Regulatory Compliance:

Both meet UL, RoHS, and REACH standards

When to Choose Each Wire

✅ Select UL1015 When:

- Operating in high-temperature industrial environments

- Requiring 600V-rated wiring for machinery

- Needing superior chemical resistance

✅ Select UL1007 When:

- Building consumer electronics or appliances

- Space-constrained low-voltage applications

- Budget-sensitive projects with lower temp needs

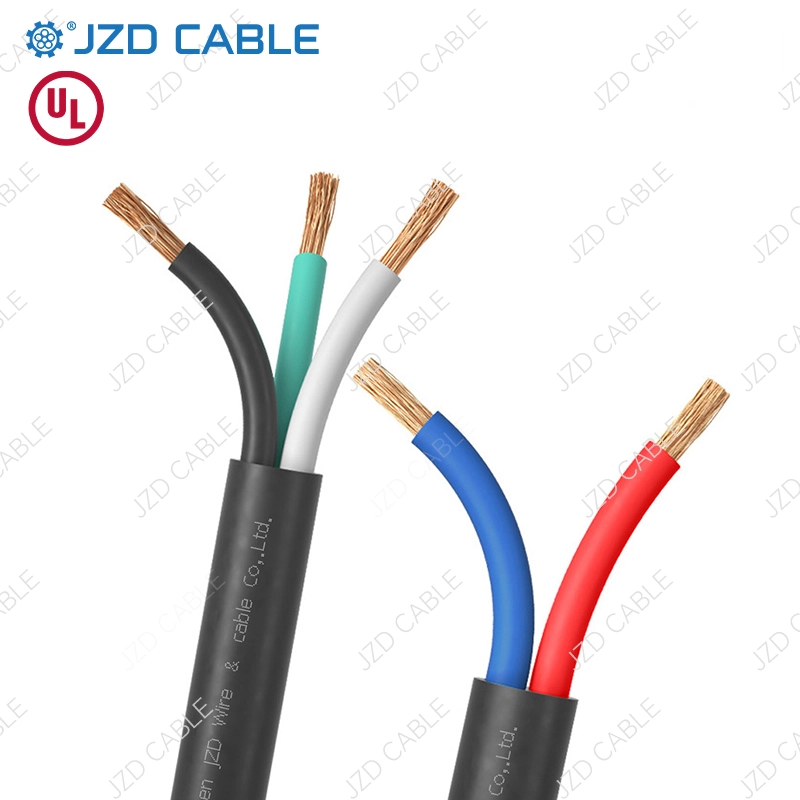

Understanding UL1007 and UL1015 differences ensures optimal performance and safety. JZD CABLE manufactures both wires with premium tinned copper conductors and certified PVC insulation.

Explore our UL-certified wire solutions:

https://jzdcable.com/product-category/ul-cable/

Technical Support:

Contact us: manager@jzdcable.com