The rapid growth of the new energy industry, particularly in the electric vehicle (EV) sector, has highlighted the critical role of specialized cables. As a vital component within EVs, these cables—often referred to as EV cables—ensure efficient power transmission and safety. Unlike conventional wiring, EV cables are designed to withstand high temperatures, voltage fluctuations, and demanding mechanical stresses. In this article, we’ll delve into the key structural features of EV cables, drawing from industry insights to explain their unique characteristics. We’ll cover conductor materials, insulation, overall structure, shielding, and sheath components in detail. By understanding these elements, manufacturers and engineers can optimize EV cable design for enhanced performance and reliability.

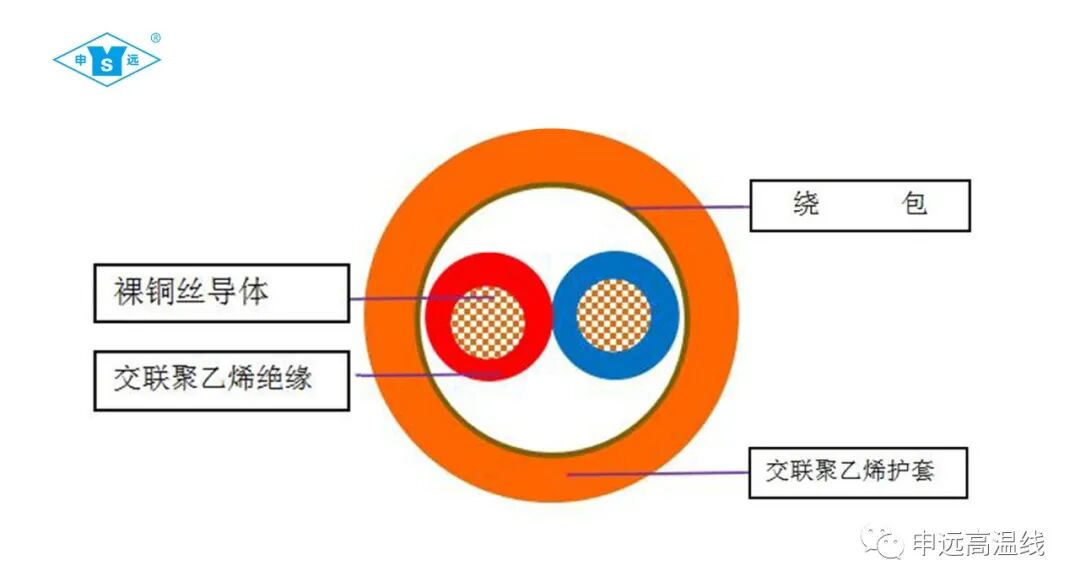

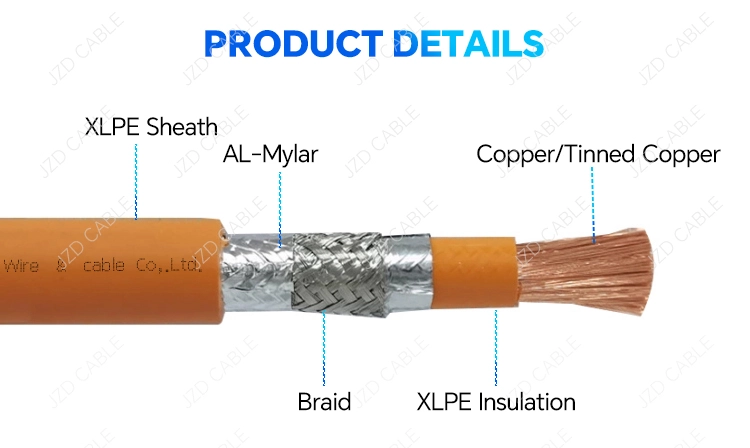

Conductor Material Features

The conductor is the core of any EV cable, and its flexibility is paramount for installation and operation in dynamic vehicle environments. The conductor’s thickness plays a decisive role in achieving this flexibility. Typically, EV cables use ultra-fine single copper wires that are intricately twisted together to form a specialized conductor structure. This design not only provides excellent elasticity but also enhances resistance to bending fatigue and extends the cable’s lifespan. Such construction allows the cable to handle frequent movements without compromising electrical conductivity or integrity.

Insulation Material Features

Insulation materials in EV cables are selected primarily for their heat resistance and mechanical strength. These properties ensure the cable can endure high operating temperatures and physical stresses without degradation. Depending on the specific application requirements, softer materials are often chosen to maintain the flexibility of the conductor structure. For instance, specialized polymers or elastomers are used to allow the twisted wires to remain supple, preventing cracks or failures during vehicle vibration or thermal cycling. This careful material selection contributes to the cable’s overall durability and safety in harsh conditions.

Structural Features

The overall structure of EV cables is engineered for robustness and adaptability, especially in multi-core designs. When multiple cores are present, they are typically stranded or twisted together. To counteract distortion caused by this twisting—such as tension or deformation—a dedicated untwisting device is employed. This equipment includes specialized stranding machines with unwinding reels that rotate counter to the twisting direction, ensuring the cable retains its shape and avoids tightening. Additionally, fillers are incorporated into the structure to achieve high concentricity in shielded cables, which is essential for maintaining uniform electrical properties in high-voltage applications. To preserve flexibility, packaging tapes are often wrapped around the stranded cores, allowing the cable to bend smoothly without kinking.

Shielding Material Features

Effective shielding is crucial for protecting EV cables from electromagnetic interference (EMI) and environmental factors. A common approach combines tin-plated copper wires with aluminum foil. The tin plating on the copper wires provides resistance to oxidation and corrosion, extending the cable’s service life in humid or varying climates. By controlling the density of these materials, the shielding function is significantly enhanced, offering superior EMI protection. Moreover, the use of finer copper wires ensures that the shielding layer does not compromise the cable’s inherent flexibility, making it ideal for tight spaces within electric vehicles.

Sheath Material Features

The outer sheath of EV cables serves as the primary defense against external wear and environmental exposure. Standardized in orange as a warning color, the sheath material is chosen based on thermal and mechanical performance. Since it directly contacts the external environment, it must offer excellent abrasion resistance to withstand friction from installation or vehicle operation. Materials such as specialized thermoplastics or elastomers are selected for their ability to endure heat buildup and physical impacts, ensuring long-term protection for the internal components. This sheath not only safeguards the cable but also contributes to overall vehicle safety by preventing short circuits or damage.

Conclusion

As the main carrier for power output in electric vehicles, high-temperature and high-voltage-resistant EV cables are pivotal to vehicle performance and safety. The research, development, and design of these cables require a holistic approach, involving collaboration across the entire supply chain—from raw material suppliers to component manufacturers. By establishing unified standards that address current usage demands and anticipate future industry trends, we can enhance EV safety, reduce design and manufacturing costs for new energy wiring harnesses, and contribute to the sustainable growth of the electric vehicle sector. Understanding the structural features outlined here empowers stakeholders to innovate and improve EV cable technology, driving the new energy revolution forward.

For more insights into EV cable innovations, stay tuned to our blog at JZD Cable.