Entering the Philippine market with your appliances or lighting products requires a crucial component: compliant power cords. The Philippine Bureau of Product Standards (BPS) mandates that all parallel construction power cords, commonly known as SPT wires, meet the PNS 163 standard. This guide provides a comprehensive overview of SPT-1, SPT-2, and SPT-3 wires, their specifications, applications, and how to avoid common selection pitfalls. Understanding these details is the first step toward ensuring your products are safe, reliable, and ready for the Philippine market.

What are SPT-1, SPT-2, and SPT-3?

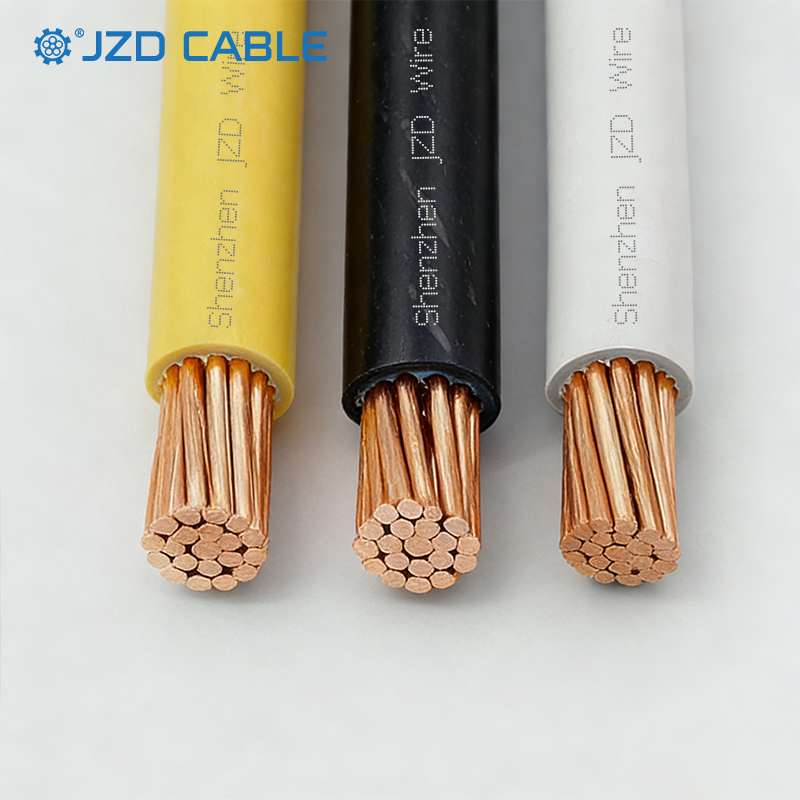

- Conductor: Made of soft copper strands for low-resistance current flow.

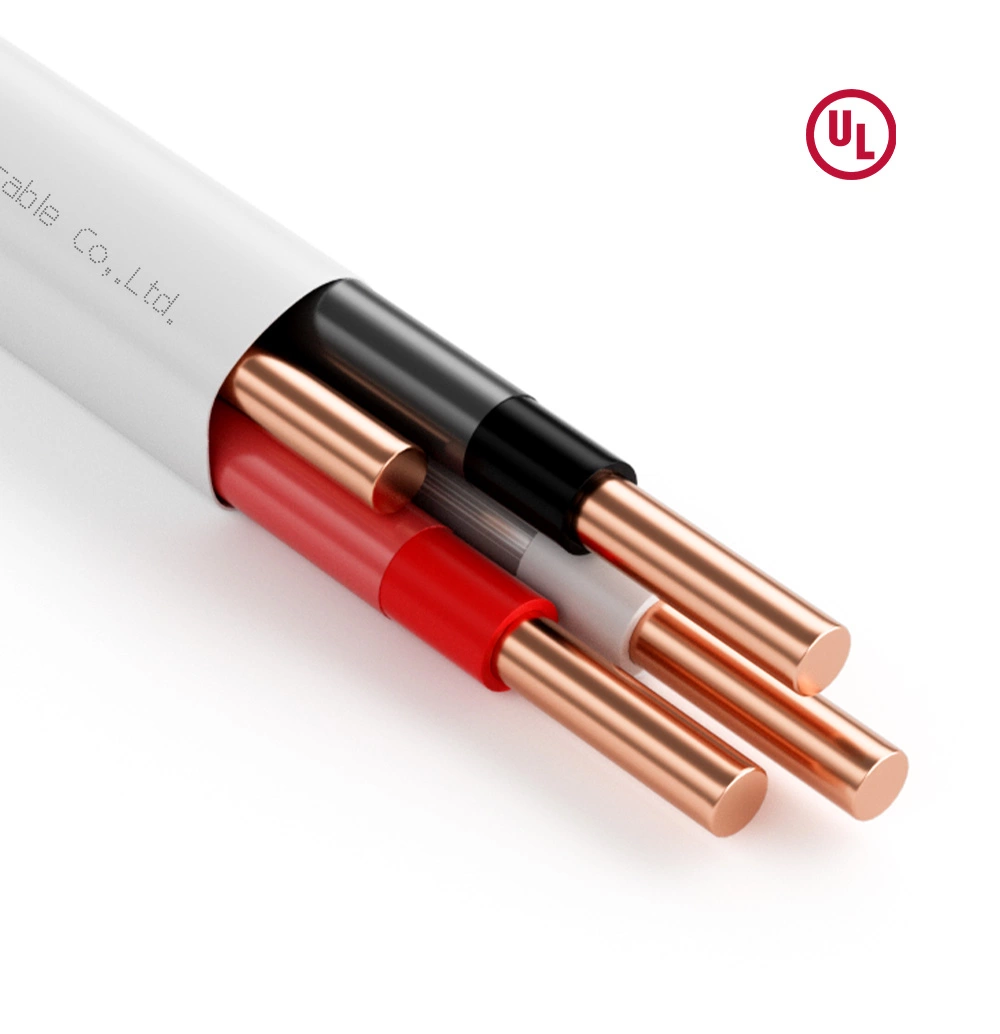

- Insulation: PVC (UL VW-1/CSA FT2 flame-retardant type), providing moisture resistance and electrical isolation. Thickness is adjusted by type (e.g., SPT-3 has thicker insulation/jacketing than SPT-1 to accommodate a higher temperature rating).

Key Features

-

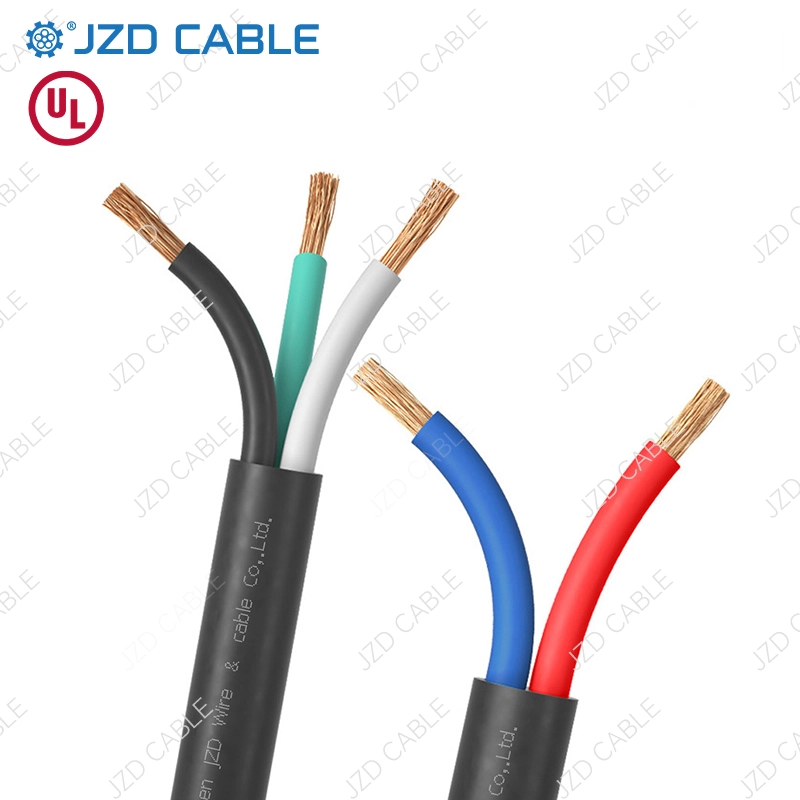

Parallel Conductors: Simplifies installation on appliances with two-pin plugs (most SPT types do not require grounding). -

Flame Retardancy: Complies with UL VW-1 (vertical flame test) and CSA FT2 (horizontal flame test), ensuring safety in residential environments. -

Flexibility: PVC insulation provides moderate flexibility, suitable for fixed or semi-fixed appliance connections (e.g., lamp cords, blender power cords). -

Certification Requirement: All SPT wires must possess BPS certification to enter the market.

Common Applications

- SPT-1: Table lamps, wall clocks, decorative lighting, small electronics (e.g., phone chargers).

- SPT-2: Floor lamps, medium-duty kitchen appliances (e.g., toasters, blenders), portable fans.

- SPT-3: Refrigerators, air conditioners, washing machines, garage door openers, high-power workshop tools.

Common Cable Selection Mistakes

-

Incorrect Conductor Size or Voltage Rating: The cable size must adequately handle the load. An undersized cable can overheat, leading to voltage drop, exceeding specifications, or unnecessarily increasing costs. -

Improper Installation: Cables must be installed according to environmental conditions and following installation codes. Excessive bending or compression can damage insulation, leading to failure or short circuits. -

Ignoring Environmental Conditions: Cables should be selected based on the operating environment. Overlooking factors like temperature, chemical exposure, and mechanical stress can cause premature aging or safety hazards. -

Using Low-Quality Cables: Choosing poor-quality cables might save costs initially but often leads to more issues, such as lack of durability, easy damage, susceptibility to short circuits, or operational failure. -

Neglecting Certifications: Overlooking certifications like UL, CE, or TUV can result in non-compliance with regulations or safety risks.

How to Avoid These Pitfalls

-

Assess environmental conditions, mechanical demands, and electrical requirements thoroughly. -

Verify certification compliance and ensure the wires meet your project’s specific parameters.