What is Australian Standard Steel Tape Armoured Cable?

-

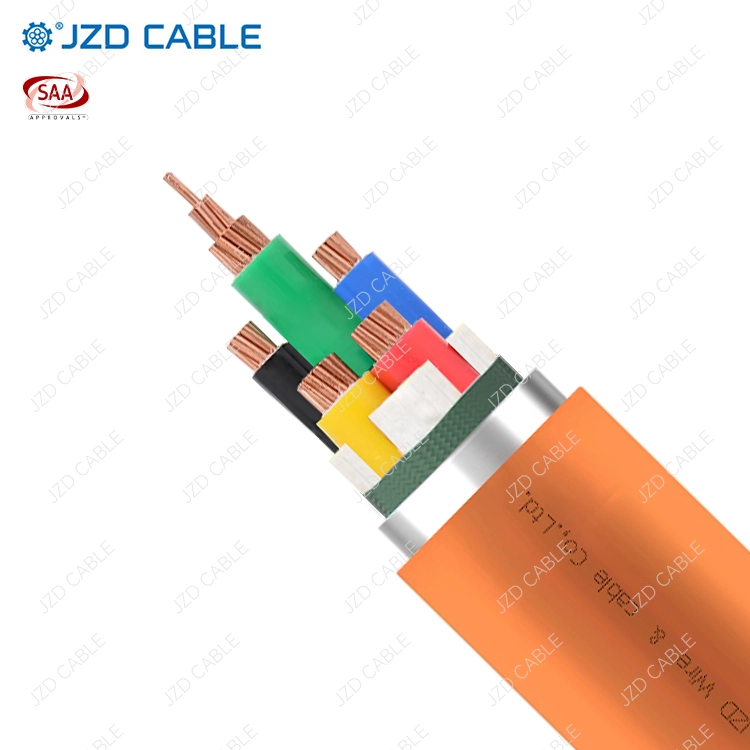

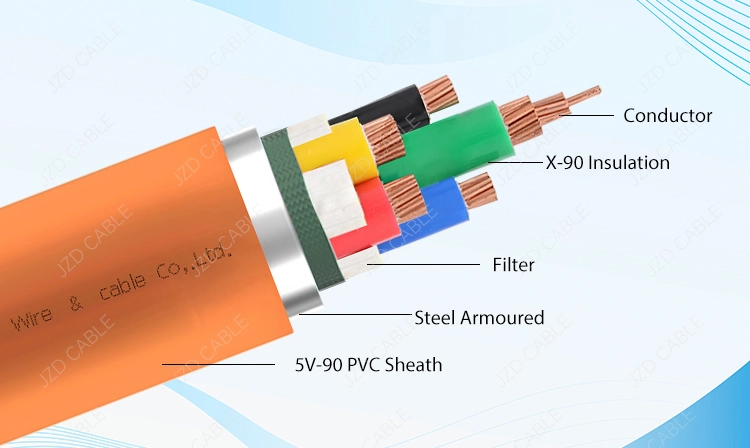

Conductor: The conductor is the core part of the armoured cable, used to transmit power or signals. Common conductor materials include copper and aluminum. -

Insulation Layer: The insulation layer is a dielectric layer surrounding the conductor, designed to prevent current leakage and scattering. -

Armour Layer: The armour layer is a special design element that makes the cable more robust, offering physical protection along with properties like pressure resistance, bending resistance, and fire resistance. -

Sheath Layer: The sheath layer is the external protective cover that prevents damage from chemicals, moisture, and mechanical impacts.

Characteristics

- High Strength Tensile and Compression Resistance: The armour layer (e.g., steel tape, steel wire, or aluminum tape) significantly enhances the cable’s tensile and compression strength, extending its service life. It is particularly suitable for complex environments like rock areas for direct burial or shaft installation.

- Anti-Corrosion and Erosion Resistance: The metal armour effectively isolates external corrosive factors such as chemicals and moisture, protecting the internal conductor and insulation to reduce performance degradation.

- Mechanical Damage Protection: The armour prevents the sheath from being punctured by sharp objects, avoiding short-circuit risks from squeezing or dragging, and reduces damage from animals like rodents.

- Multi-Environment Adaptability: These cables are ideal for various installation methods, including direct burial, cable trench laying, and shaft installation. They perform well in harsh environments such as chemical plants, metallurgical facilities, and mines, and can be paired with flame-retardant, corrosion-resistant sheaths for broader applications.

Applications

- Power Systems: Used for high-voltage transmission (e.g., 35kV and above) and power equipment, requiring resistance to mechanical tension and environmental erosion. Common in thermal power plants, hydropower stations, submarine cables, and wind farms.

- Industrial and Manufacturing: Steel tape armoured cables resist high-temperature dust in steel plants; thick steel wire armoured cables with flame-retardant and anti-static properties are used in mines; corrosion-resistant variants suit chemical enterprises.

- Transportation and Municipal Engineering: Applied in high-speed rail/subway tunnels to withstand vibration and humidity; port cranes use fine steel wire armoured cables for dragging and salt corrosion resistance; municipal street lights and underground monitoring systems often employ steel tape armour.

- Construction and Civil Fields: Used in high-rise building shafts to bear tensile forces, and for direct burial along roads, squares, and railways to prevent external damage.

Common Mistakes in Cable Selection

-

Incorrect conductor size or rated voltage, which may cause overheating, voltage drops, or cost overruns. -

Improper installation methods, such as excessive bending or compression, damaging insulation and causing short circuits. -

Ignoring environmental conditions like temperature, chemical exposure, and mechanical stress, leading to premature aging or safety hazards. -

Using low-quality cables that save costs initially but result in issues like poor wear resistance, damage, or failure. -

Neglecting certifications (e.g., UL, CE, TUV), risking non-compliance or safety violations.

To Avoid These Pitfalls

- Assess environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.