What Are H03VVH2-F and H05VVH2-F Cables?

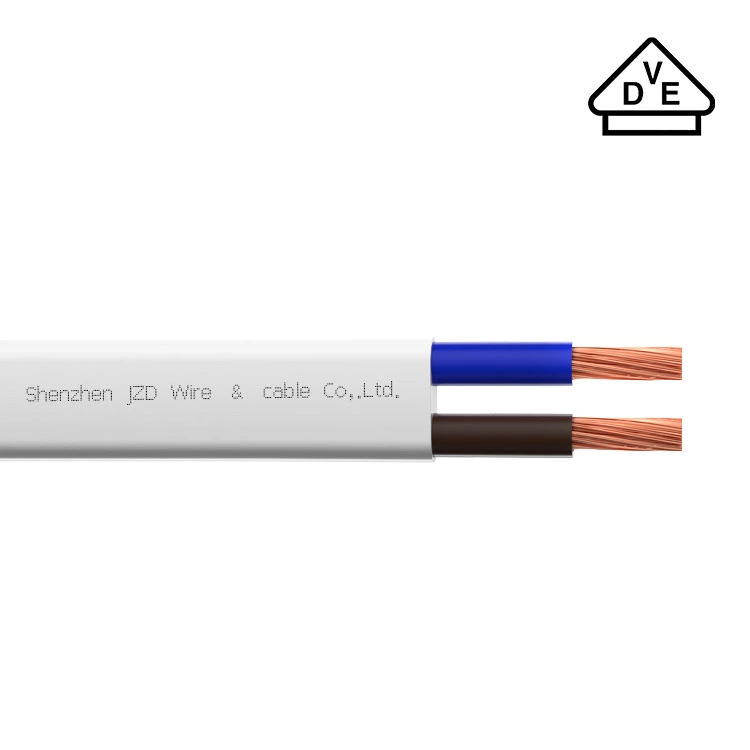

- H: Harmonized Code, indicating compliance with European technical standards.

- 03/05: Rated voltage—300/300V for H03VVH2-F and 300/500V for H05VVH2-F.

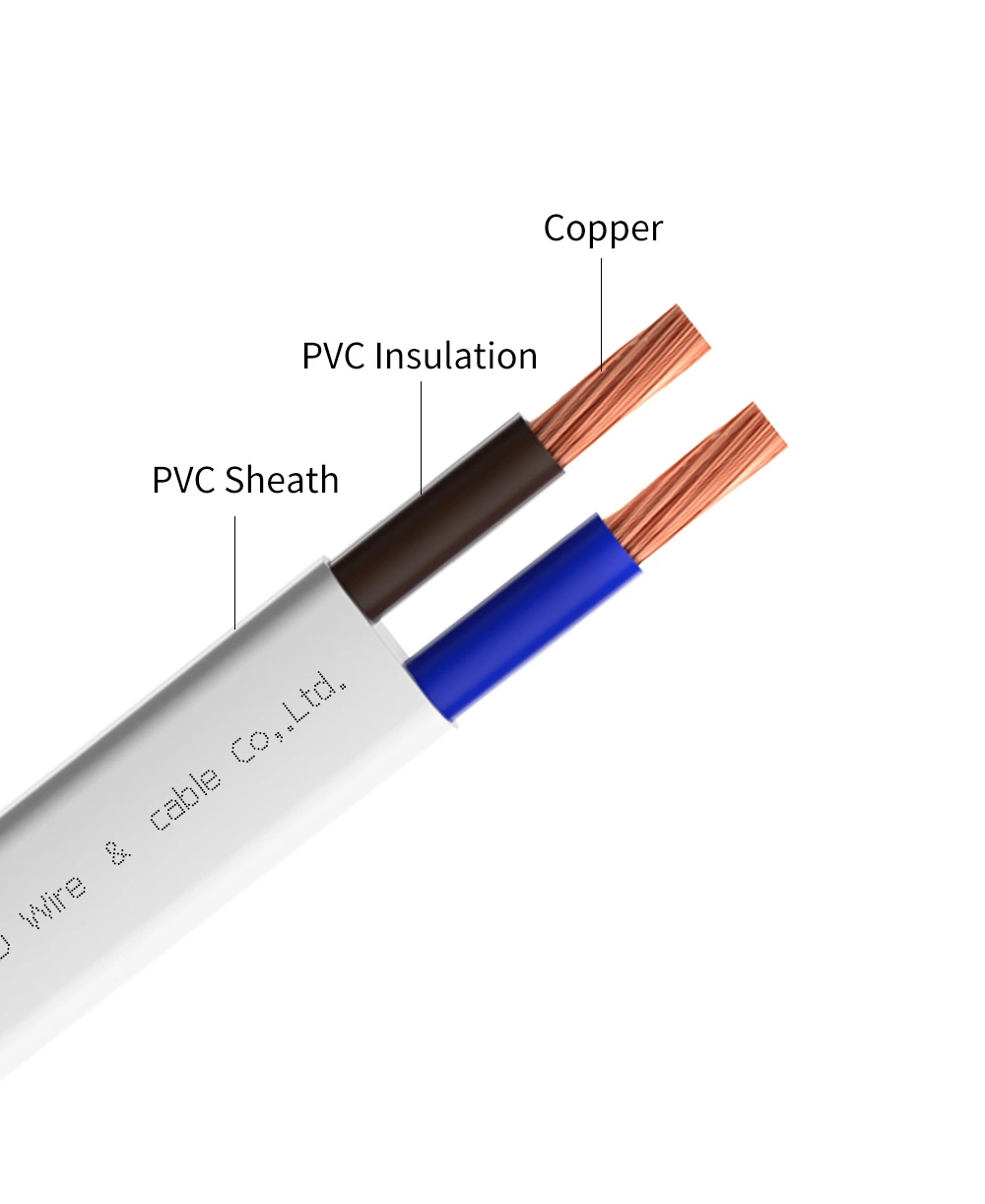

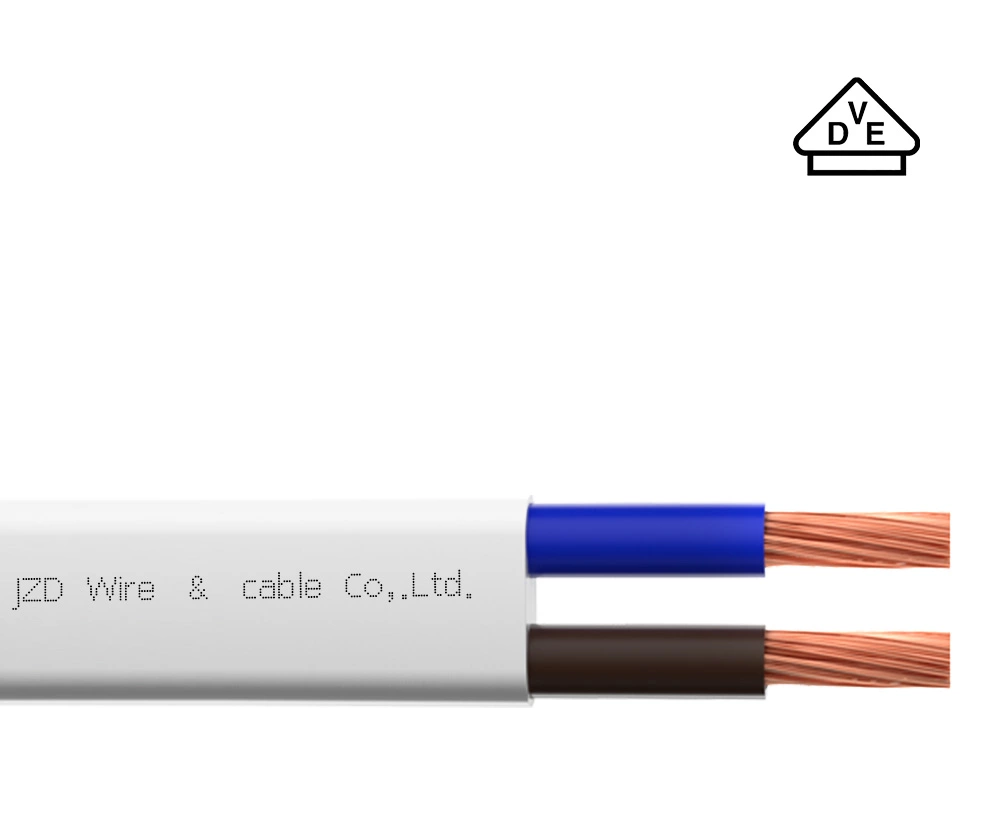

- V: Thermoplastic PVC insulation, offering chemical resistance and insulation.

- V: PVC sheath for added durability and insulation.

- H2: Two-core parallel flat structure.

- F: Flexible design with fine-stranded copper conductors for easy bending and installation.

Key Features

- Ultra-flexible copper conductors and PVC insulation/sheath retain pliability even in low temperatures.

- Ideal for portable indoor/outdoor equipment.

2. Broad Applicability

- Suitable for dry or damp environments (e.g., industrial plants, control systems).

- Supports control, measurement, and signal transmission.

3. Safety and Reliability

- VDE-certified, compliant with RoHS directives, and flame-retardant (meets IEC 60332-1/HD 405.2).

- Low failure rate and minimal maintenance needs.

4. Standardization

- Adheres to IEC 60228 conductor standards, compatible with VDE and CCC certifications.

Typical Applications

- Household Appliances: Refrigerators, washing machines, and air conditioners in humid areas (avoid direct heat contact).

- Industrial Equipment: Machinery, factory instruments, and control systems requiring moderate stress resistance.

- Construction and Decor: Fixed installations in furniture, partition walls, prefabricated buildings, or conduits.

- Special Environments: Ships, ports, metallurgy, and oil/gas settings requiring oil resistance, EMI protection, or high-temperature tolerance.

Common Selection Errors to Avoid

-

Incorrect Conductor Size/Voltage Rating: Undersized cables cause overheating, voltage drops, and increased costs. -

Improper Installation: Excessive bending or compression damages insulation, leading to short circuits. -

Ignoring Environmental Factors: Temperature, chemical exposure, or mechanical stress accelerate aging. -

Using Low-Quality Cables: May save costs short-term but risks premature failure, wear, or safety hazards. -

Overlooking Certifications: Non-compliance with UL, CE, or TUV standards can result in regulatory issues.

Solutions

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.