What is SIS Wire?

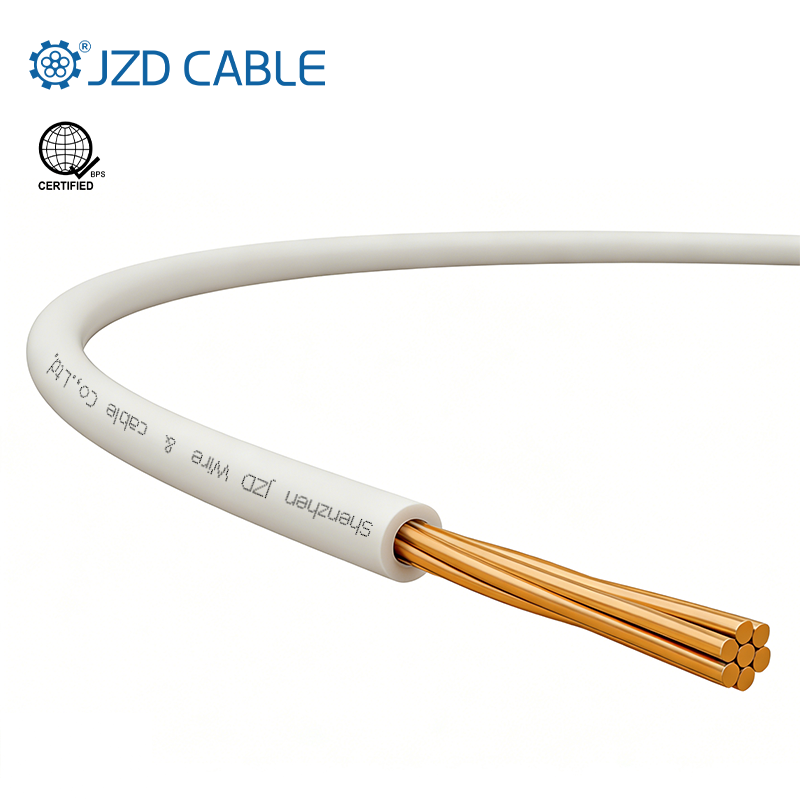

- Stranded Copper Conductors: Unlike solid core wires, SIS wire uses multiple fine strands of copper bundled together. This design offers superior flexibility, making it easier to route and terminate within the tight confines of electrical panels and enclosures.

- Heat-Resistant Insulation: The conductor is insulated with a robust material, most commonly Cross-Linked Polyethylene (XLPE). XLPE is a thermoset material, meaning it retains its integrity and does not melt under high temperatures, unlike thermoplastic insulations.

Key Features and Benefits

- High-Temperature Rating: SIS wire is typically rated to operate safely at temperatures up to 90°C in dry locations. This high thermal stability ensures reliable performance even in environments where electrical equipment generates significant heat.

- Excellent Voltage Rating: With a standard rating of 600 volts, SIS wire is suitable for a wide range of control and power applications within panels.

- Flame Resistance: A crucial safety feature, SIS wire complies with stringent flame tests like the VW-1 vertical flame test. This significantly reduces the risk of fire propagation, a vital consideration in densely wired panels.

- Durability and Space Efficiency: The XLPE insulation provides excellent resistance to abrasion, chemicals, and cracking. Additionally, its thin-wall insulation allows for a more compact design, enabling higher density wiring within panels.

Common Applications

- Industrial Switchboards and Panelboards: It is the standard wire for internal wiring, connecting circuit breakers, relays, and other components.

- Control Panels and Cabinets: Perfect for automation systems, motor control centers (MCCs), and any enclosed panel where reliable signal transmission and power routing are essential.

- Instrumentation Wiring: Used within control apparatus for instruments and sensors that require stable performance.

- Commercial and Industrial Machinery: Provides the internal wiring for heavy machinery and equipment control systems.

Choosing the Right SIS Wire

- Gauge (AWG Size): Choose the conductor size based on the current-carrying capacity required by your circuit. For example, 14 AWG is common for control signals, while 12 AWG or 10 AWG might be used for higher-current circuits.

- Compliance: Always ensure the wire is certified to relevant standards, such as UL 44 and CSA, guaranteeing it meets rigorous safety and performance benchmarks.

- Environment: Confirm the application is a dry, indoor location as intended for SIS wire.