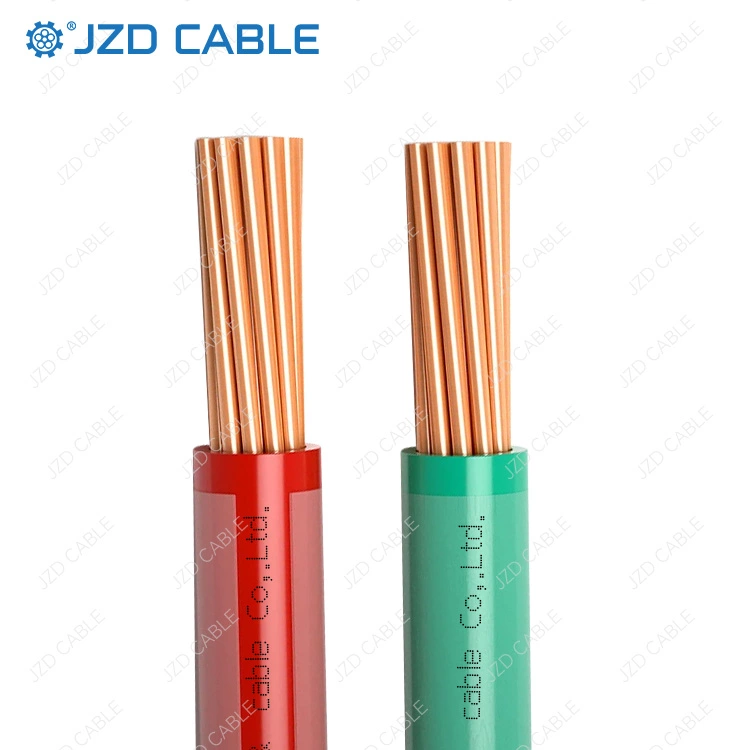

What is T90 Nylon Wire?

Characteristics of T90 Nylon Wire

- Abrasion Resistance: High surface hardness and low friction coefficient enable it to withstand wear during installation, dragging, and laying, extending service life.

- Impact Toughness: Capable of enduring compression, collision, and other mechanical stresses to protect internal conductors and insulation.

- High Strength and Flexibility: High tensile and tear strength make it suitable for bending applications.

2.Good Chemical Resistance

- Resistant to oils, fuels, solvents, cleaners, and other chemicals, making it ideal for environments like chemical plants or engineering machinery exposed to corrosive substances.

- Wide operating temperature range: -40°C to +90°C, meeting demands for high-temperature environments.

- Halogen-Free and Eco-Friendly: Produced without adding halogens, resulting in low smoke and toxicity when burned, compliant with ROHS standards.

- Flame Retardancy: Excellent self-extinguishing properties, achieving standards like UL VW-1 and IEC 60332 through additive modifications, suitable for construction and rail transit.

- Lightweight: Small outer diameter and light weight with low static friction coefficient, facilitating easy installation.

- Easy Processability: Can be extruded with thin walls for uniform sheathing, offering cost-effectiveness.

Typical Applications

- Building and Fixed Wiring: Suitable for conduit installation in buildings, with a small outer diameter and smooth surface that reduces friction, increasing wire capacity and minimizing insulation damage. It has a long service life (over 40 years) and is ideal for scenarios like highway monitoring equipment and lighting fixtures.

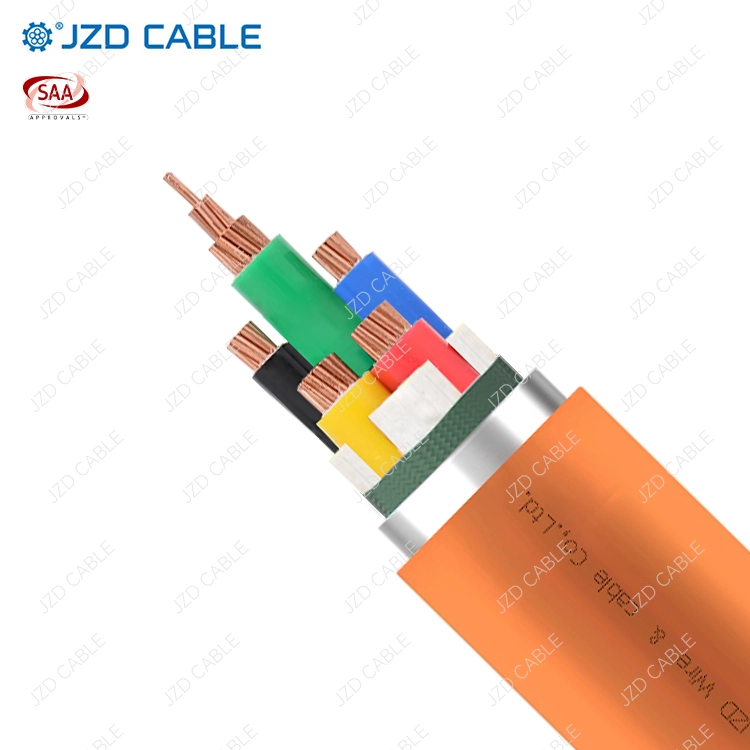

- Industrial and Mobile Cables: In applications requiring frequent dragging or high mechanical stress (e.g., robot cables, drag chains), the nylon sheath’s abrasion and impact resistance protect internal conductors, making it perfect for industrial automation and engineering machinery.

- Automotive and Aerospace: Used in automotive wiring harnesses and components (e.g., engine compartments, brake systems) due to oil and high-temperature resistance. Its lightweight nature also helps reduce vehicle weight. In aerospace, it meets stringent needs for chemical corrosion and cold resistance (-40°C).

- Electronic and Electrical Equipment: Suitable for connectors, switches, and sockets where flame retardancy (e.g., UL-certified THHN cables) or anti-static properties are required. Materials like PA12 offer flexibility and hydrolysis resistance for sensors or medical device cables.

- Special Environmental Protection: Resistant to rodents and chemicals (e.g., oils, acids, alkalis), it is used in high-risk settings like petrochemical plants or underground installations. Modified versions meet fire safety standards for data centers and rail transit.

Common Mistakes in Cable Selection and How to Avoid Them

- Incorrect conductor size or voltage rating, causing overheating or voltage drops.

- Improper installation methods, such as over-bending, which damages insulation.

- Ignoring environmental factors like temperature or chemical exposure.

- Using low-quality cables to save costs, leading to premature failure.

- Neglecting certifications like UL, CE, or TUV, resulting in non-compliance.

- Assess environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.