What is TC-ER Cable?

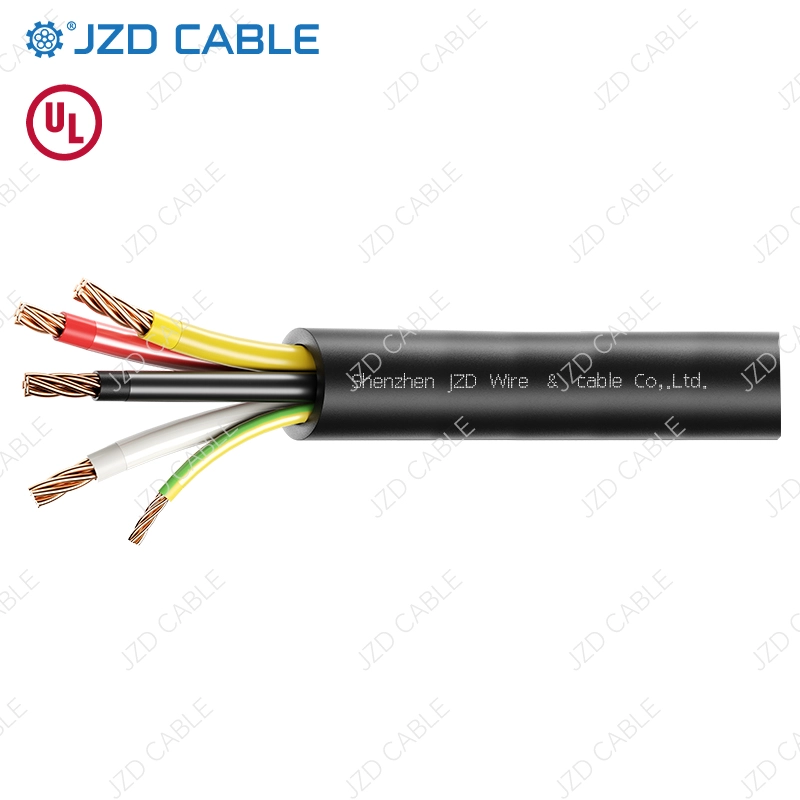

Characteristics of TC-ER Cable

-

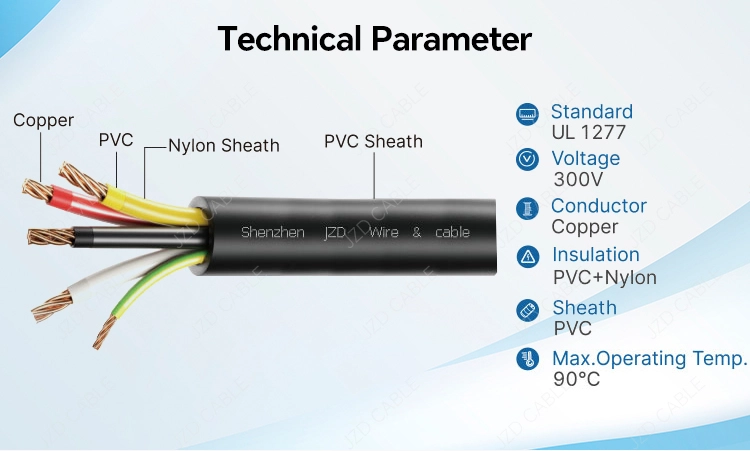

Excellent Heat Resistance: Broad working temperature range, capable of withstanding temperatures up to 90°C, meeting demands for extreme environments. During short circuits, the conductor temperature does not exceed 250°C, ensuring safe operation. -

Strong Physical and Chemical Stability: High mechanical strength, tensile resistance, oil resistance, and resistance to acid/alkali corrosion ensure high chemical reliability. The nylon sheath offers oil resistance, UV resistance, and excellent anti-aging properties, contributing to a long service life. -

Advantages in Signal Transmission: Primarily used for thermocouple signal transmission. The materials are matched to the thermocouple to ensure consistent thermoelectric voltage and reduce electromagnetic interference. -

Wide Environmental Adaptability: Suitable for both damp (≤90°C) and dry (≤90°C) environments, making it applicable for hazardous locations and outdoor use. The sheath is flame-retardant and wear-resistant, simplifying installation and maintenance. -

Stringent Safety Certifications: Complies with UL standards such as UL 1277, having passed fire resistance and flame retardancy tests.

Typical Applications

-

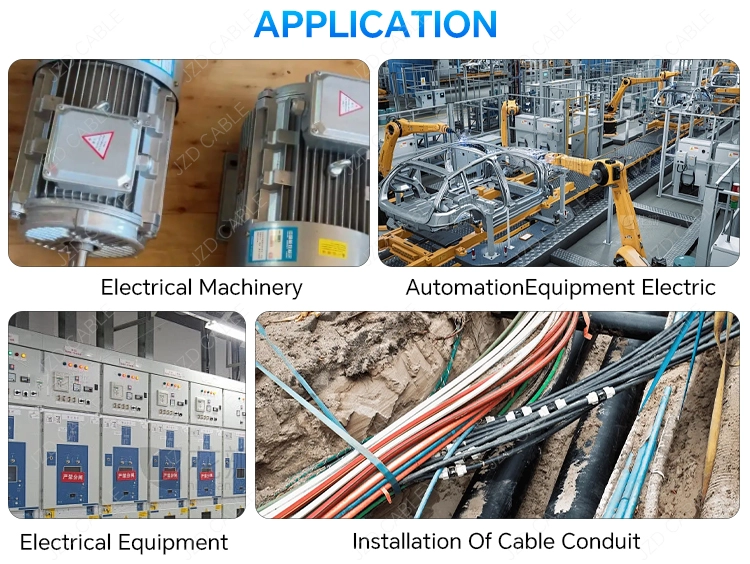

Power and Industrial Control Fields: Used in power systems, industrial controls, instrumentation, and internal wiring of control cabinets to provide reliable power transmission. Within wind farms, it is used inside wind turbines for cable tray or conduit installation. -

Outdoor and Special Environments: Often used in cable trays, raceways, or messenger-supported outdoor locations, featuring twist resistance, oil resistance, and UV resistance. Can be directly buried in hazardous locations or used for Class 1 control circuits. -

New Energy and Rail Transportation: Due to its energy-efficient and environmentally friendly properties, it is widely used in new energy sectors (like wind and solar power) and rail transportation. -

Markets Requiring UL Certification: Compliant with standards like UL 1277, it is exported to North American markets and suits applications such as power, lighting, and signal transmission.

Common Selection Mistakes

How to Avoid These Pitfalls:

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure the cable meets project-specific parameters.

By applying these selection criteria, engineers can prevent performance mismatches and ensure reliable long-term operation.