In the realm of electronic device design and manufacturing, the choice of internal hook-up wire is critical to a product’s safety, reliability, and longevity. Among various standard wires, UL1007 stands out as a preferred choice for engineers due to its excellent balance of properties. But what makes this wire so versatile and reliable? This article delves into the specs, applications, and key selection criteria for UL1007 wire to guide your decision-making.

What is UL1007 Wire?

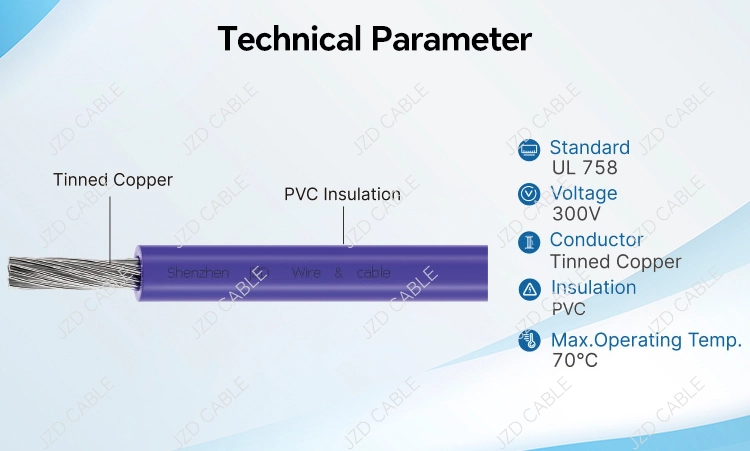

Key Features of UL1007

- Soft and easy to bend, with a rounded, glossy tinned conductor for simple termination.

2.Reliable Conductor & Insulation

- Conductors use single or stranded bare/tinned copper for excellent conductivity.

- Eco-friendly PVC insulation ensures uniform thickness, easy stripping, and cutting.

3.High Safety & Flame Resistance

- Passes VW-1 and CSA FT1 vertical flame tests, reducing fire risks.

- Resistant to acids, alkalis, moisture, and mold.

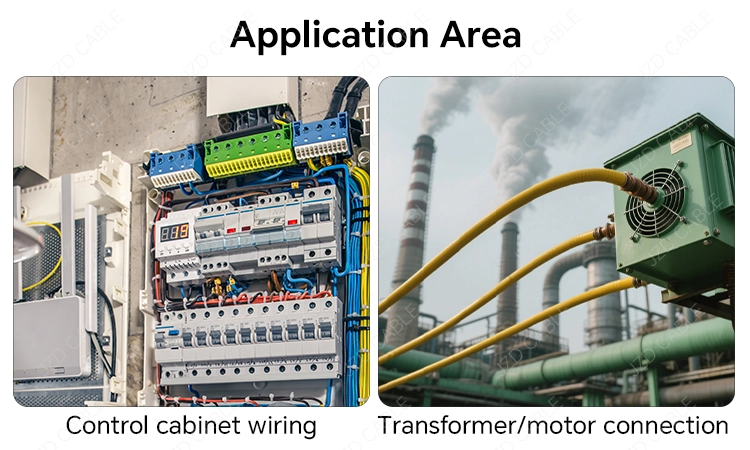

Typical Applications

- Household Appliances: Internal wiring for washing machines, refrigerators, microwaves, etc.

- Electronics & Instruments: Wiring for computers, mobile device components, sensors, and meters.

- Industrial & Special Environments: Suitable for corrosive settings (e.g., labs, chemical plants) or high-temperature equipment.

Common Mistakes to Avoid When Selecting UL1007 Cable

-

Incorrect Conductor Size/Voltage Rating Undersized cables can overheat, causing voltage drops or failure. Always match the load requirements.

-

Improper Installation Avoid sharp bends or compression during installation to prevent insulation damage and short circuits.

-

Ignoring Environmental Conditions Consider temperature, chemical exposure, and mechanical stress to avoid premature aging or safety hazards.

-

Using Low-Quality Cable Cheap cables may save costs initially but lead to failures, wear, or malfunctions.

-

Overlooking Certifications Ensure compliance with UL, CE, or TUV standards to meet regulations and ensure safety.

How to Choose the Right UL1007 Cable

- Evaluate environmental conditions, mechanical stress, and electrical requirements.

- Verify certifications and ensure the cable meets your project’s specific parameters.