When it comes to power distribution systems, selecting the right cable type is crucial for ensuring safety, reliability, and cost-effectiveness. Among the most commonly used power cables are YJV and YJV22, both serving critical roles in electrical infrastructure. While they share some similarities, their structural differences make them suitable for distinct applications. This comprehensive guide will help you understand the key differences between YJV and YJV22 cables, their respective advantages, and how to choose the right option for your specific needs.

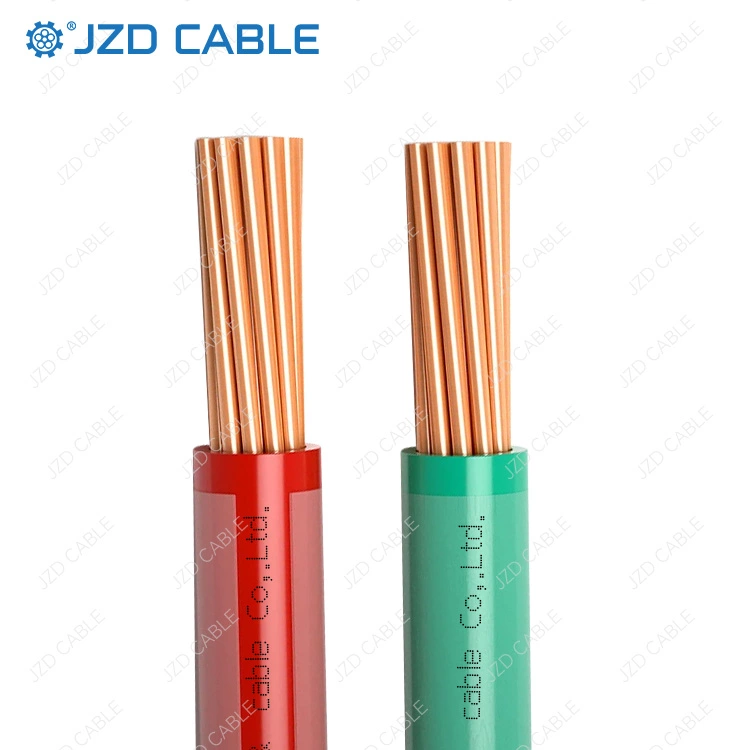

What is YJV Cable?

YJV cable, which stands for “Cross-Linked Polyethylene Insulated Polyvinyl Chloride Sheathed Power Cable,” is a fundamental building block in electrical systems. The “YJ” denotes XLPE (cross-linked polyethylene) insulation, while “V” represents the PVC sheath. This cable features a copper core conductor with XLPE insulation and a single-layer PVC protective sheath.

Key Characteristics of YJV Cable:

- Structure: Simple design with no armor layer

- Insulation: XLPE material providing excellent electrical properties

- Temperature Rating: 90°C continuous operating temperature

- Voltage Rating: Typically 0.6/1kV to 26/35kV depending on specification

- Flexibility: Good bending radius suitable for various installation scenarios

What is YJV22 Cable?

YJV22 cable builds upon the YJV design with enhanced mechanical protection. The designation “YJV22” indicates “Cross-Linked Polyethylene Insulated Steel Tape Armored Polyvinyl Chloride Sheathed Power Cable.” The number “22” specifically refers to the steel tape armor combined with PVC outer sheathing, creating a dual-layer protection system.

Key Characteristics of YJV22 Cable:

- Structure: Enhanced design with steel tape armor between inner and outer sheaths

- Armor Protection: Steel tape provides superior mechanical protection

- Temperature Rating: 90°C continuous operating temperature (same as YJV)

- Voltage Rating: Comparable to YJV with additional mechanical robustness

- Applications: Suitable for harsh environments requiring extra protection

Common Features Between YJV and YJV22 Cables

Despite their structural differences, YJV and YJV22 cables share several important characteristics:

- Insulation Material: Both utilize XLPE insulation, offering excellent electrical properties and thermal resistance

- Temperature Performance: Identical 90°C continuous operating temperature and 250°C short-circuit withstand temperature

- Electrical Properties: Similar insulation resistance and voltage withstand capabilities

- Conductor Material: Typically copper conductors with optional tinned copper variations

- Voltage Ratings: Comparable voltage classifications across various specifications

Key Differences Between YJV and YJV22 Cables (With Comparison Table)

The primary differences lie in their mechanical properties and application suitability:

|

Parameter

|

YJV Cable

|

YJV22 Cable

|

|---|---|---|

|

Structure

|

Simple: Conductor + XLPE insulation + PVC sheath

|

Complex: Conductor + XLPE insulation + steel tape armor + PVC sheath

|

|

Mechanical Protection

|

Basic protection only

|

Excellent crush resistance and impact protection

|

|

Bending Radius

|

Smaller, more flexible

|

Larger due to armor layer

|

|

Installation Flexibility

|

High – suitable for complex routing

|

Moderate – requires careful bending

|

|

Crush Resistance

|

Limited

|

Excellent (steel tape armor)

|

|

Rodent/Animal Protection

|

Minimal

|

Good protection against biting/gnawing

|

|

Direct Burial Suitability

|

Not recommended without additional protection

|

Suitable for direct burial

|

|

Weight

|

Lighter

|

Heavier due to armor layer

|

|

Cost

|

More economical

|

Higher initial cost

|

|

Maintenance

|

Easier access and handling

|

More complex due to armored structure

|

Structural Differences Explained:

The absence of armor in YJV cables makes them more vulnerable to mechanical damage but easier to install in confined spaces. YJV22’s steel tape armor provides exceptional protection against crushing forces, impact damage, and environmental hazards, making it ideal for demanding installation conditions.

Selection Guidelines: Choosing Between YJV and YJV22

When to Choose YJV Cable:

- Indoor Applications: Building interiors, commercial spaces, shopping malls

- Conduit/Cable Tray Installations: Where cables are protected by raceways or trays

- Limited Space Scenarios: Tight bends and complex routing requirements

- Cost-Sensitive Projects: Where budget constraints are significant

- Controlled Environments: Areas with minimal risk of mechanical damage

When to Choose YJV22 Cable:

- Direct Burial Applications: Underground installations without additional protection

- High-Risk Environments: Areas with potential mechanical impact or crushing forces

- Industrial Settings: Factories, manufacturing plants with heavy equipment

- Outdoor/Exposed Locations: Where cables are subject to environmental stresses

- Critical Infrastructure: Projects where reliability is paramount despite higher costs

- Rodent-Prone Areas: Locations requiring protection against animal damage

Important Considerations:

- Environmental Assessment: Evaluate soil conditions, potential mechanical stresses, and environmental factors

- Installation Method: Consider whether cables will be buried, placed in conduits, or installed in trays

- Long-Term Maintenance: Factor in accessibility for future inspections and repairs

- Budget Constraints: Balance initial costs against long-term reliability needs

- Local Regulations: Ensure compliance with regional electrical codes and standards

Why Choose JZD Cable for Your YJV and YJV22 Needs?

At JZD Cable, we specialize in manufacturing high-quality power cables that meet international standards. Our YJV and YJV22 cables undergo rigorous quality control processes to ensure:

- Certification Compliance: All cables meet relevant UL, CE, and other international standards

- Customized Solutions: We offer tailored specifications to match your project requirements

- Technical Support: Expert guidance on cable selection and installation best practices

- Competitive Pricing: Cost-effective solutions without compromising quality

- Reliable Performance: Proven track record in various industrial and commercial applications

Whether you’re working on a residential complex, industrial facility, or infrastructure project, our team can help you select the optimal cable solution for your specific needs.

Conclusion

Understanding the differences between YJV and YJV22 cables is essential for making informed decisions in electrical projects. While YJV offers flexibility and cost-effectiveness for protected indoor applications, YJV22 provides the mechanical robustness needed for challenging environments. By carefully assessing your project requirements and consulting with experienced professionals, you can ensure optimal performance, safety, and longevity for your electrical systems.

For expert advice on cable selection or to learn more about our comprehensive product range, visit jzdcable.com or contact our technical team today.