What is UL1015?

Features of UL1015:

-

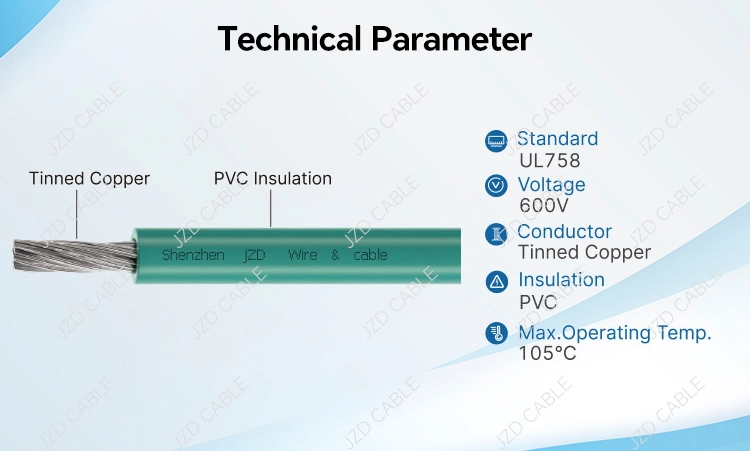

Excellent High-Temperature Resistance With a rated temperature of 105°C, it performs reliably in high-heat environments such as electronic devices and motor connections. -

High Voltage Rating Supports up to 600V, meeting the requirements of both household and industrial equipment. -

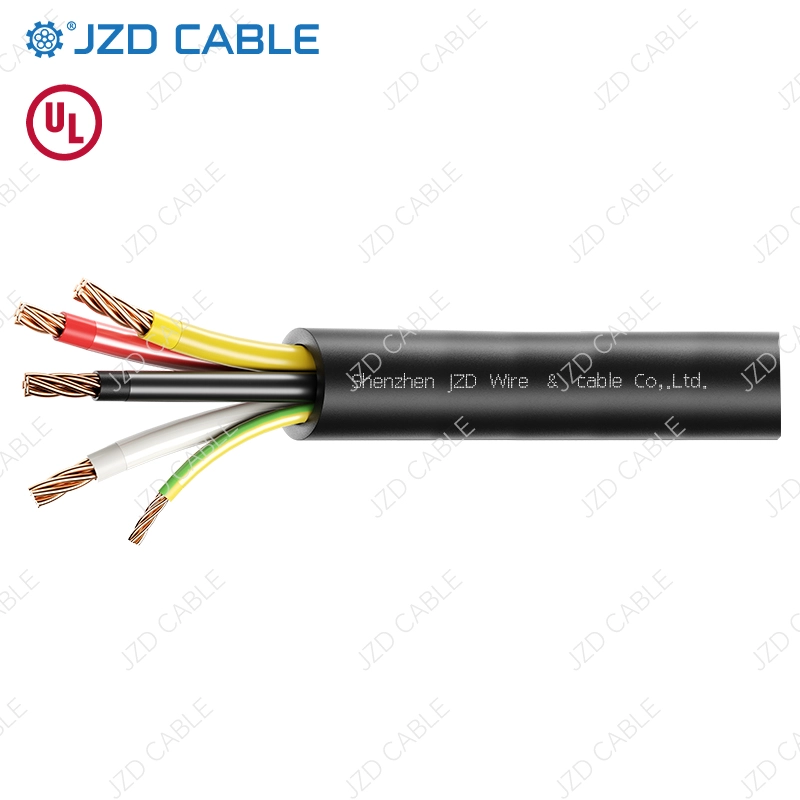

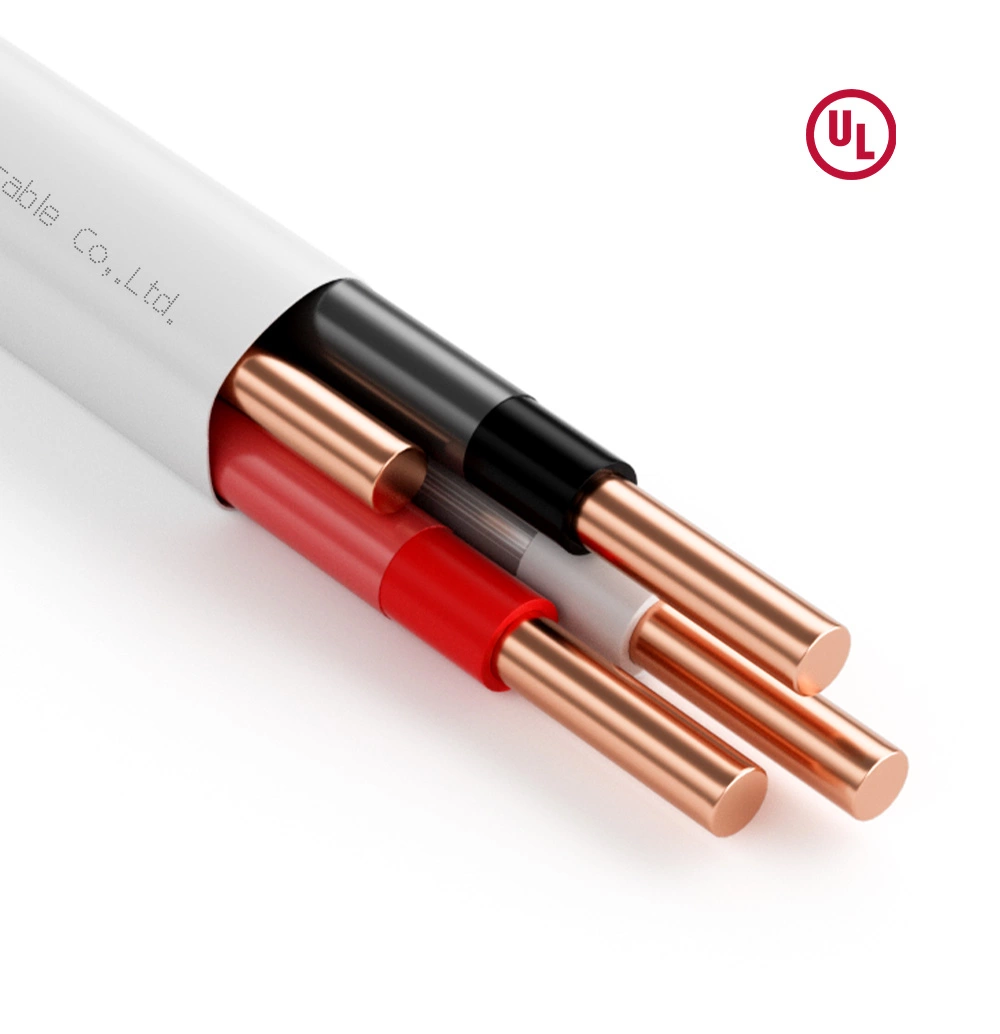

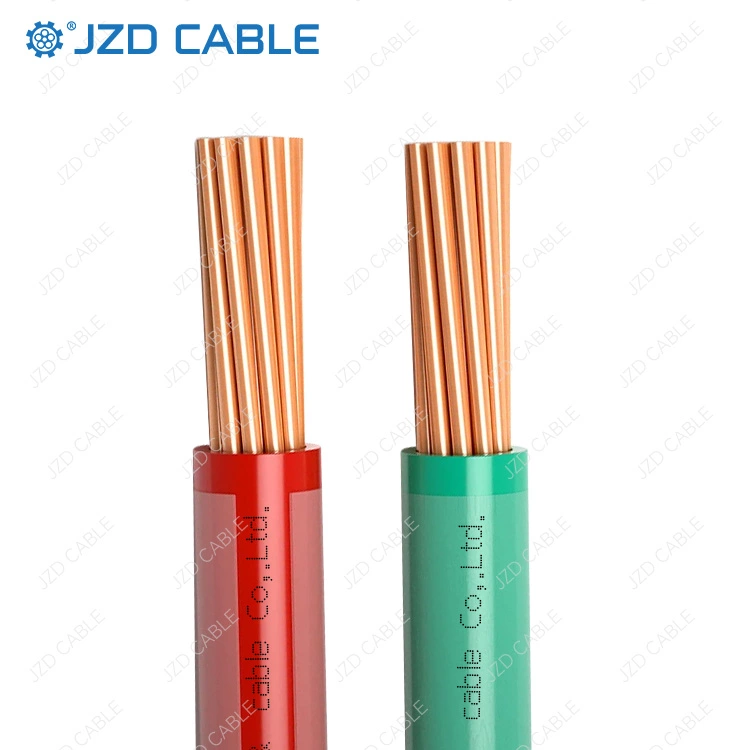

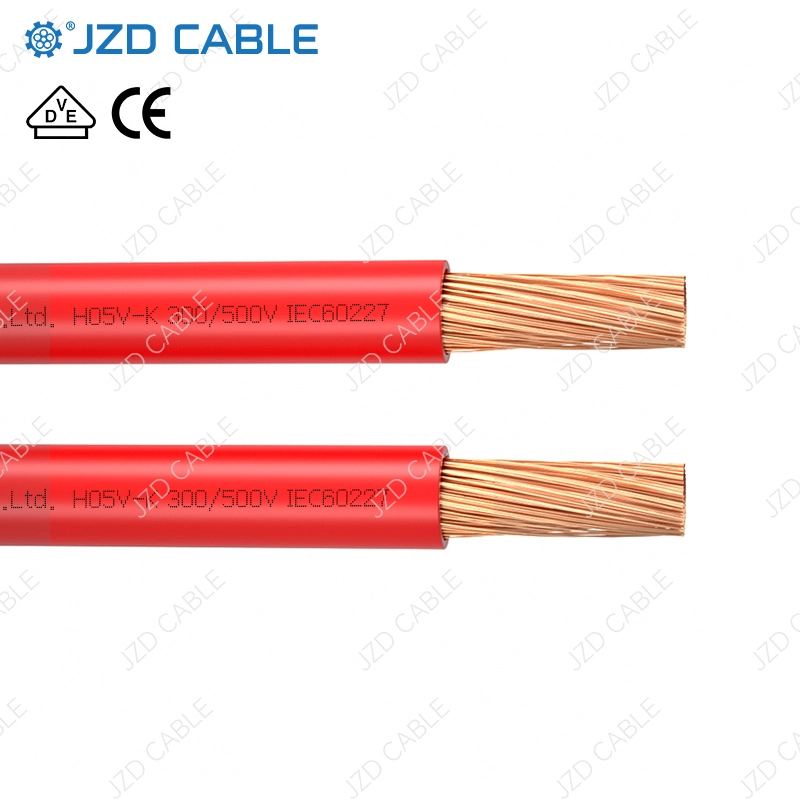

Reliable Conductor and Insulation Materials The conductor is made of single or stranded bare/tinned copper, ensuring superior conductivity. The insulation layer uses eco-friendly PVC, which is uniform in thickness, easy to strip, and simple to cut. -

High Flame Retardancy and Safety Passes VW-1 and CSA FT1 vertical flame tests, significantly reducing fire risks. It also offers resistance to acids, alkalis, moisture, and mold.

Typical Applications:

- Household Appliances and Lighting Equipment

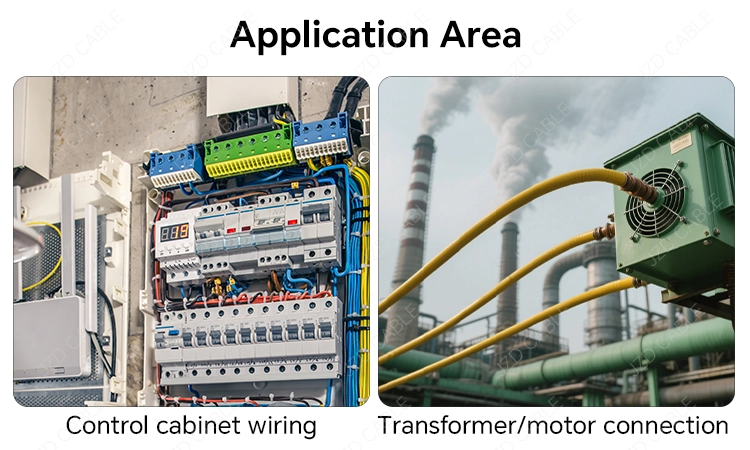

- Industrial and Mechanical Equipment

- Medical and Chemical Industries

- Building and Control Circuits

Common Mistakes in Selecting UL1015 Cables:

-

Incorrect conductor size or voltage rating, leading to overheating, voltage drops, or non-compliance. -

Improper installation methods, such as over-bending or compressing the cable, which can damage insulation and cause short circuits. -

Ignoring environmental conditions like temperature, chemical exposure, or mechanical stress. -

Choosing low-quality cables to save costs, resulting in reduced durability, frequent failures, or safety hazards. -

Overlooking certifications like UL, CE, or TUV, which may lead to non-compliance with regulations.

How to Avoid These Pitfalls:

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure the wire meets project-specific parameters.