Are you torn between NM-B Cable and ordinary non-metallic cables for your building wiring projects? This article delves into the unique advantages, application scenarios, and key selection criteria for NM-B Cable. Discover why engineers increasingly prefer NM-B solutions and how JZD Cable provides safe, reliable wiring solutions for your projects.

What is NM-B Cable?

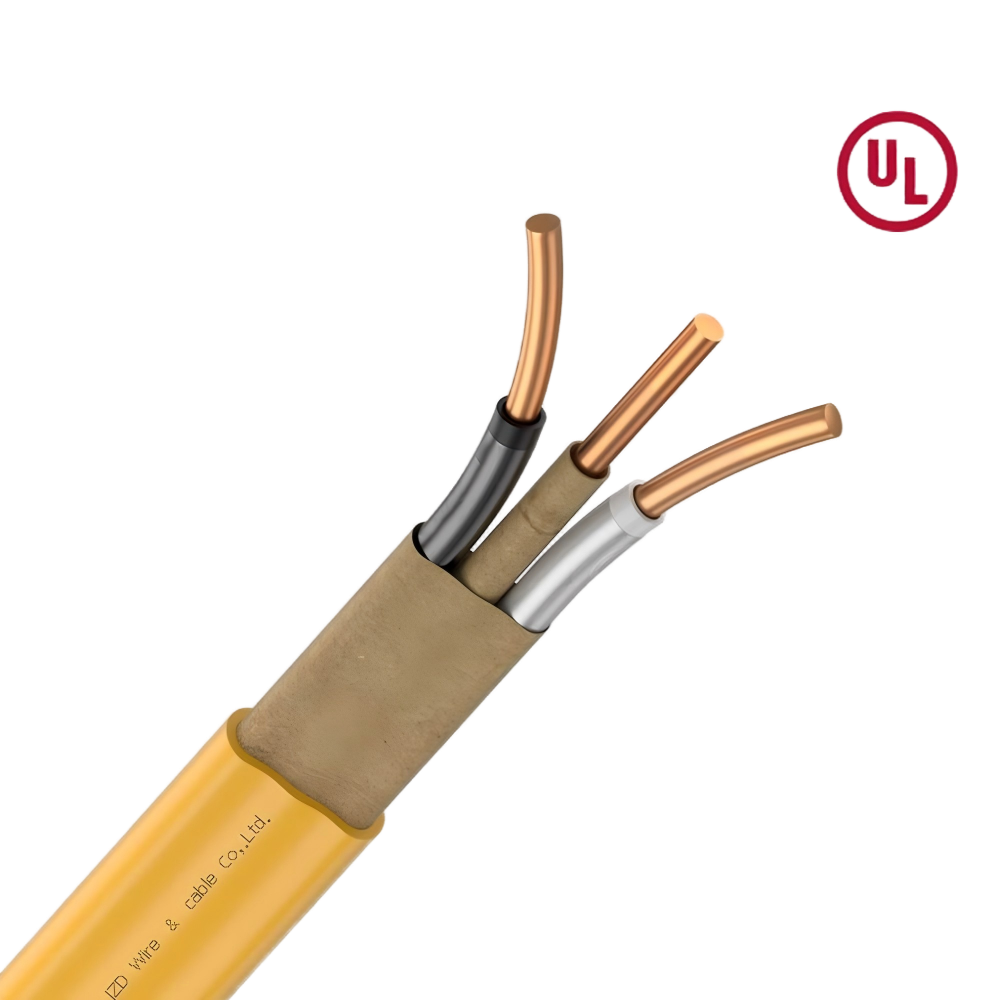

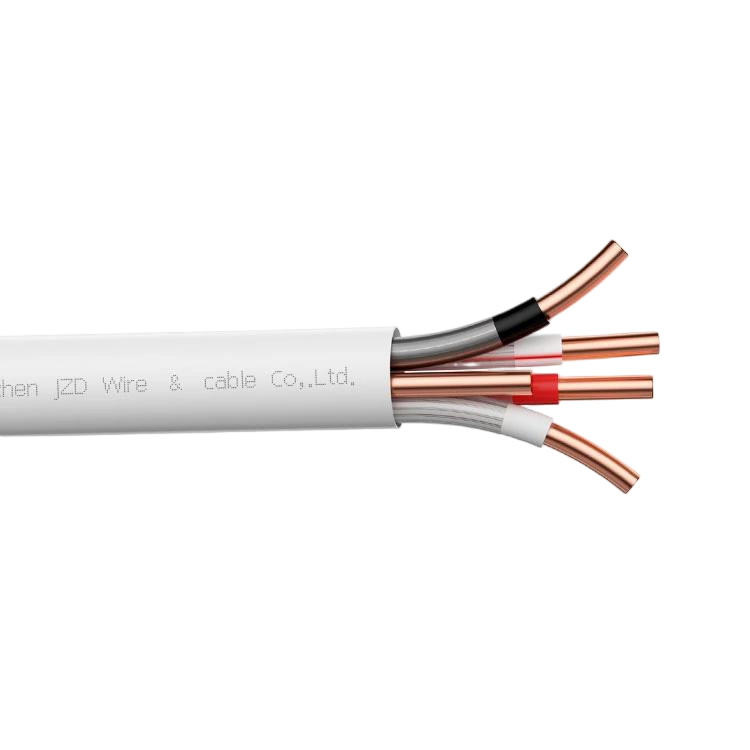

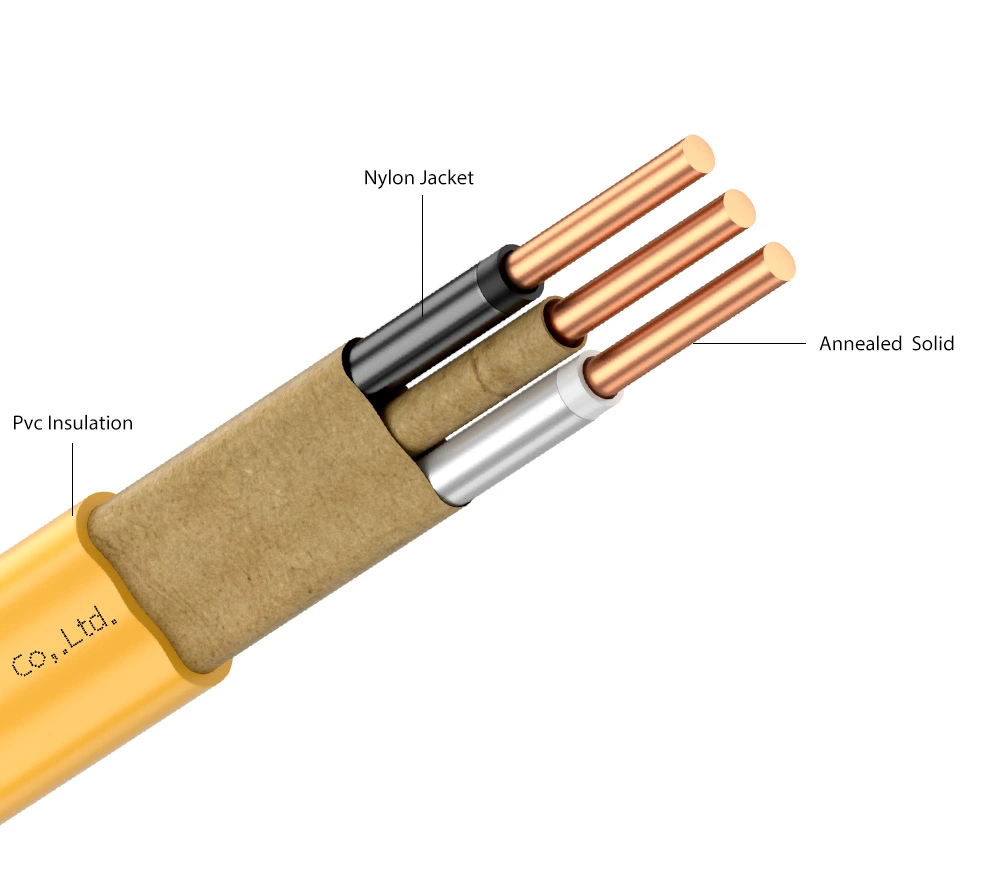

- Conductor: Annealed copper wire (soft and flexible for easy installation).

- Insulation: Each conductor is wrapped with a nylon+PVC composite insulation layer—nylon offers ozone resistance, chemical corrosion resistance, and mechanical friction protection, while PVC enhances insulation performance and reduces costs.

- Sheath: The outermost layer is a 30-mil (approx. 0.76mm) PVC sheath.

Key Features and Applications

-

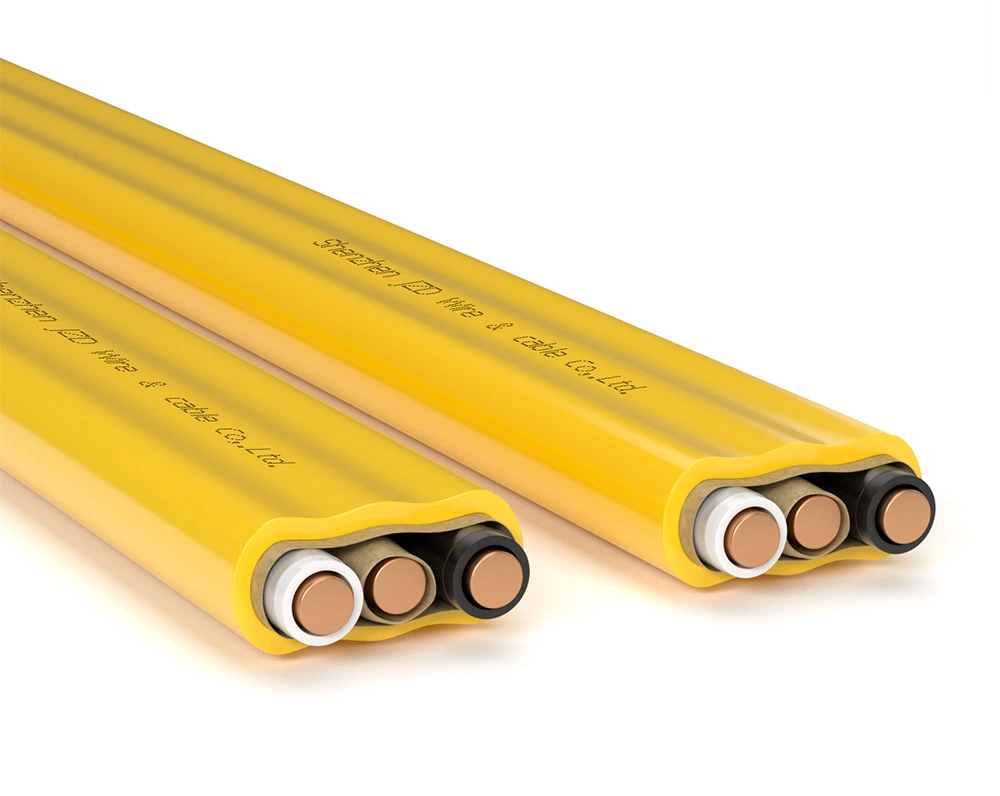

Easy Installation: Flexible and easy to thread through conduits, reducing installation complexity. -

Durability: The PVC sheath resists abrasion and impact, with the nylon layer adding extra mechanical protection. -

Safety: Non-metallic sheath eliminates metal corrosion risks and meets ROHS environmental standards, ideal for homes and safety-sensitive applications.

Typical Applications:

-

Residential Wiring: Used as branch circuits to connect power sources to outlets, switches, ceiling lights, fans, and other loads—making it a core material for home electrical systems. -

Light Commercial Buildings: Suitable for power transmission in dry environments like offices, shops, and apartments, meeting the power needs of small commercial equipment. -

Concealed/Exposed Installation: Can be installed in voids within masonry or tile walls (avoid excessive moisture) or directly exposed on ceilings or walls in dry locations (must comply with NEC spacing requirements).

Common Mistakes in Cable Selection

-

Incorrect Conductor Size or Voltage Rating: Undersized cables can overheat, cause voltage drops, or exceed specifications, increasing costs unnecessarily. -

Improper Installation: Cables must be installed according to environmental conditions and specifications. Over-bending or compression can damage insulation, leading to short circuits. -

Ignoring Environmental Conditions: Select cables based on operating environments. Neglecting temperature, chemical exposure, or mechanical stress can lead to premature aging or safety hazards. -

Using Low-Quality Cables: Cheap cables may save costs initially but often result in failures, such as poor wear resistance, damage, or malfunction. -

Overlooking Certifications: Disregarding UL, CE, or TUV certifications may lead to non-compliance or safety risks.

Tips to Avoid Issues:

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure cables meet project-specific parameters.

- By applying these criteria, engineers can prevent performance mismatches and ensure long-term reliability.