In the realm of electrical wiring for North American residential, commercial, and light industrial buildings, NMD-90 non-metallic sheathed cable stands out for its core role. Renowned for its superior safety, flexible installation, and broad applicability, this cable is a top choice for various projects. This guide delves into the structure, advantages, typical applications, and crucial selection pitfalls of the NMD-90 cable. As a professional wire and cable manufacturer, JZD Cable is committed to providing high-quality, internationally certified NMD-90 cables and other reliable products for your needs.

What is NMD-90 Cable?

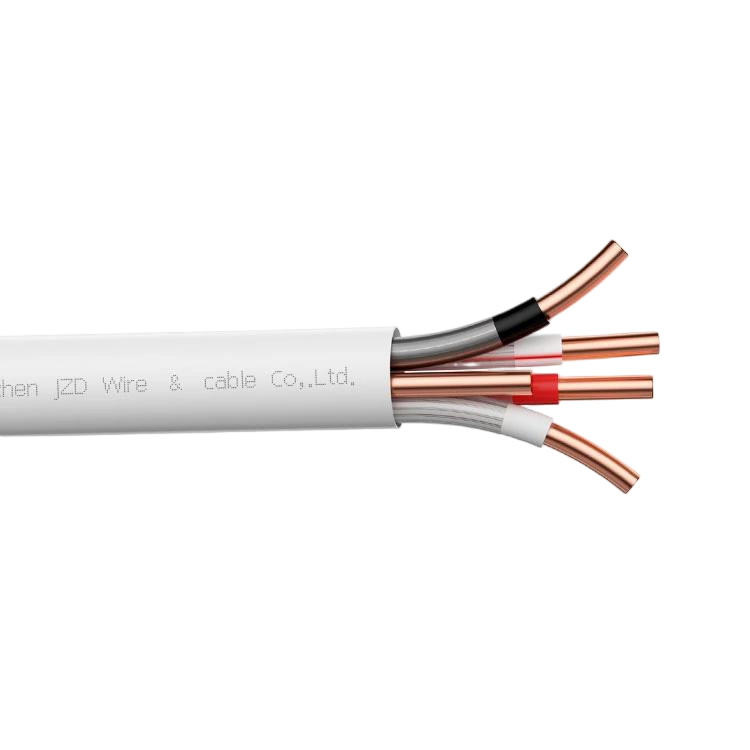

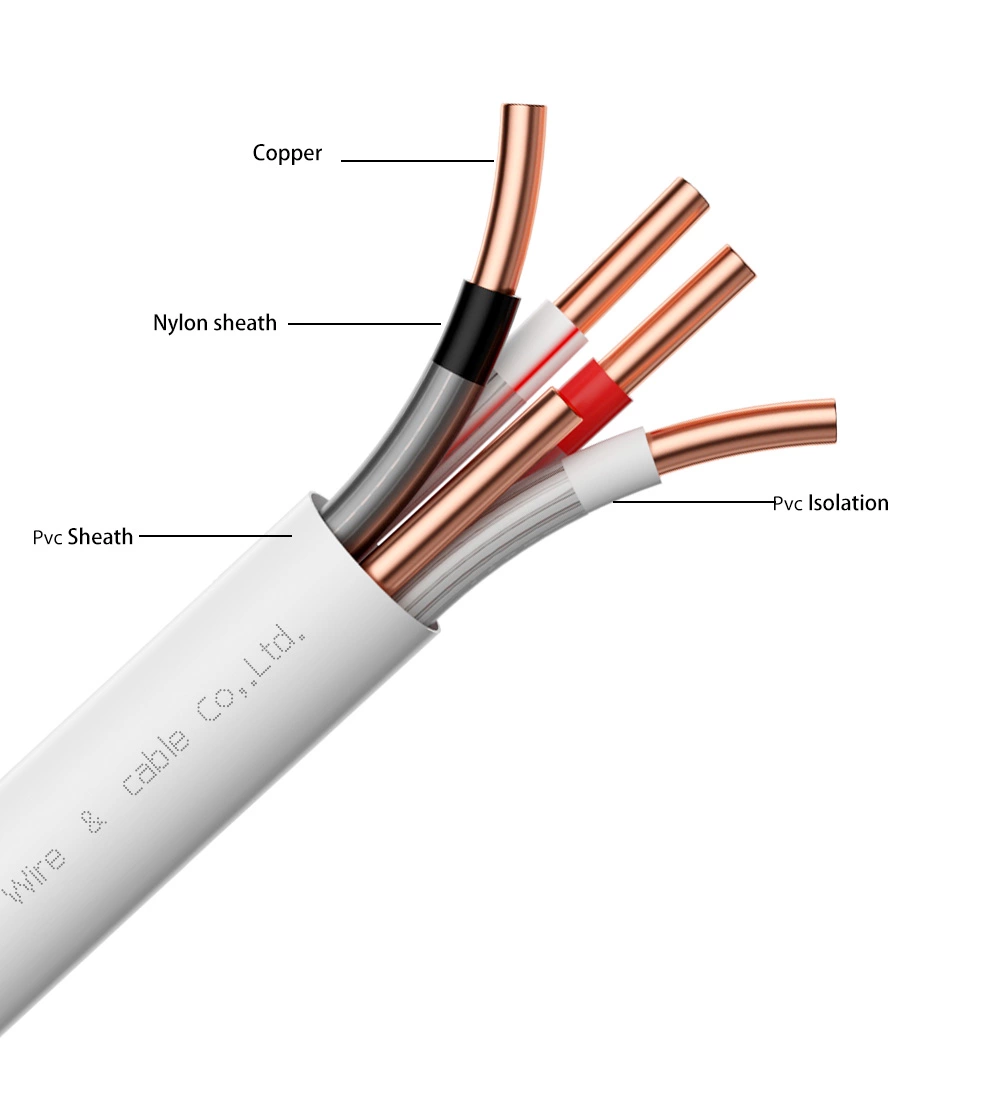

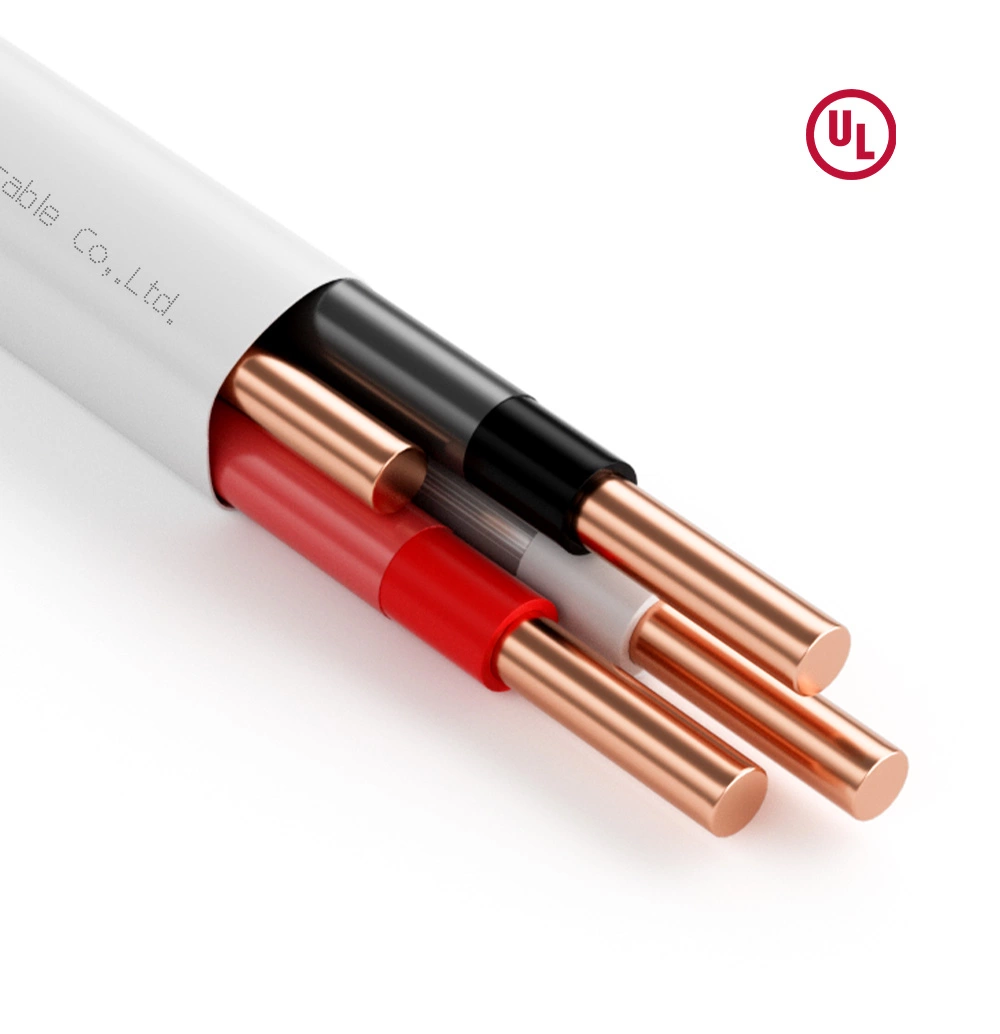

Structure of NMD-90 Cable:

- Conductor: Annealed copper wire for flexibility and ease of installation.

- Insulation: Each conductor is wrapped in a nylon+PVC composite insulation layer. Nylon provides resistance to ozone, chemicals, and mechanical friction, while PVC enhances insulation performance and reduces costs.

- Sheath: The outermost layer is a PVC sheath.

Features of NMD-90 Cable

-

Easy Installation: Excellent flexibility allows for easy pulling through conduits, reducing installation difficulty. -

High Durability: The PVC sheath offers abrasion and impact resistance, with the nylon layer further enhancing mechanical protection. -

Safety: The non-metallic sheath eliminates corrosion risks and meets RoHS environmental standards, making it ideal for residential and safety-sensitive applications.

Typical Applications:

-

Residential Wiring: Used as branch circuits to connect power sources to outlets, switches, ceiling lights, fans, and other loads. It serves as a core wiring material for home electrical systems. -

Light Commercial Buildings: Suitable for power transmission in dry environments such as offices, retail stores, and apartments, meeting the electrical needs of small commercial equipment. -

Concealed/Exposed Installations: Can be installed in voids within masonry or tiled walls (avoiding excessive moisture) or directly exposed on ceilings or walls in dry locations (complying with NEC spacing requirements).

Common Mistakes in Cable Selection

-

Incorrect Conductor Size or Voltage Rating: Undersized cables may overheat, causing voltage drops or exceeding specifications, unnecessarily increasing costs. -

Improper Installation: Cables must be installed according to environmental conditions and specifications. Over-bending or compression can damage insulation, leading to short circuits. -

Ignoring Environmental Conditions: Factors like temperature, chemical exposure, and mechanical stress must be considered. Unsuitable cables may age quickly or pose safety risks. -

Using Low-Quality Cables: While cheaper initially, poor-quality cables may lead to failures, such as wear, damage, or short circuits. -

Overlooking Certifications: Neglecting UL, CE, or TUV certifications may result in non-compliance or safety hazards.

To Avoid These Pitfalls:

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Verify certification compliance and ensure the cable meets project-specific parameters.

Why Choose JZD Cable?

- Reliable Performance: Rigorous testing ensures our cables deliver exceptional electrical and mechanical performance.

- Expert Support: Our team provides technical guidance to help you select the right cable for your project.

- Competitive Pricing: We offer cost-effective solutions without compromising quality.