What Is Twin and Earth Cable?

Key Features of Twin and Earth Cable

-

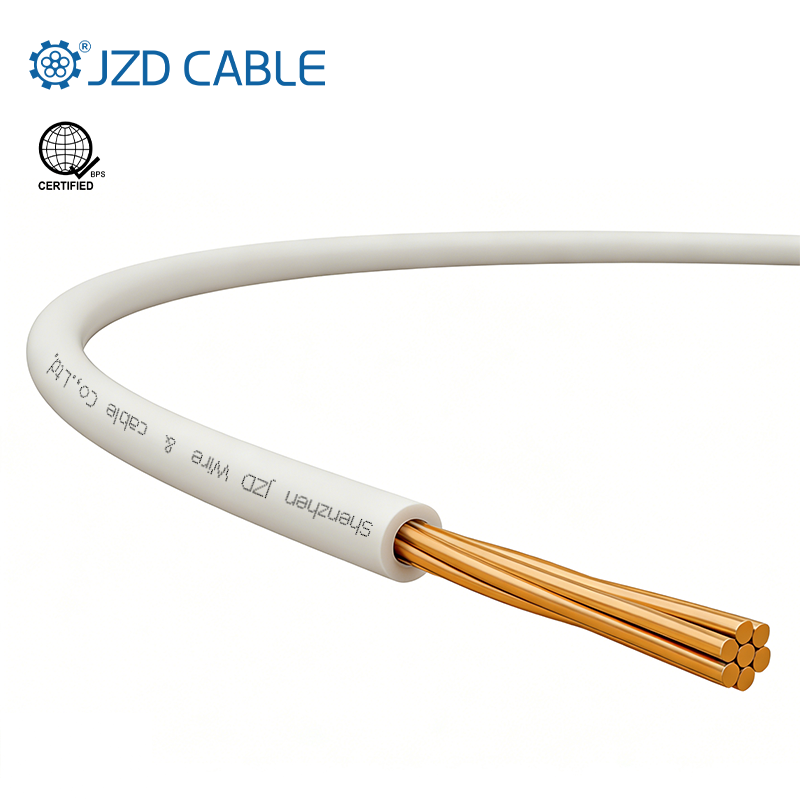

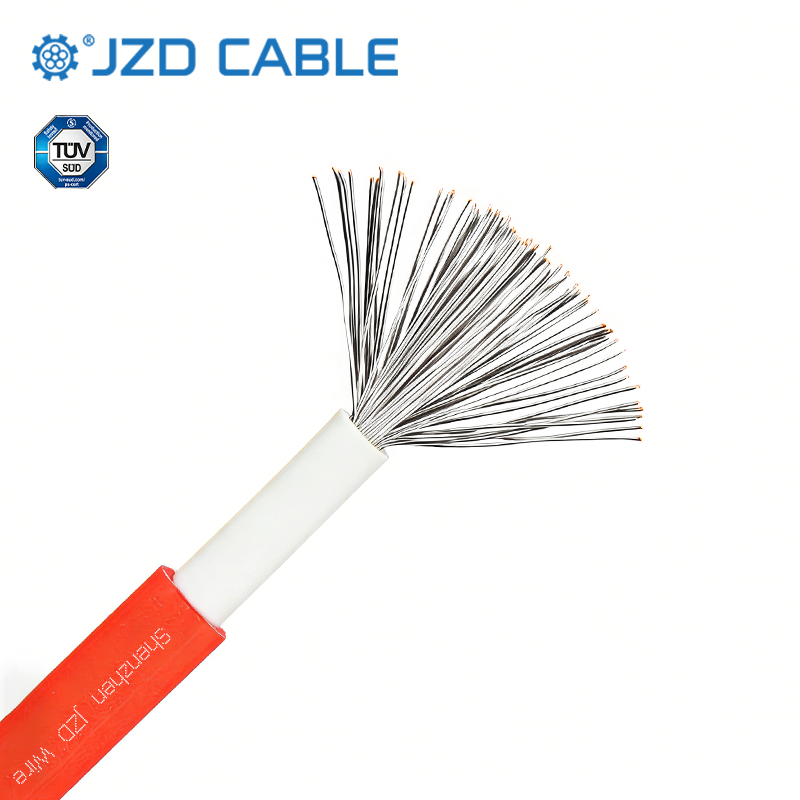

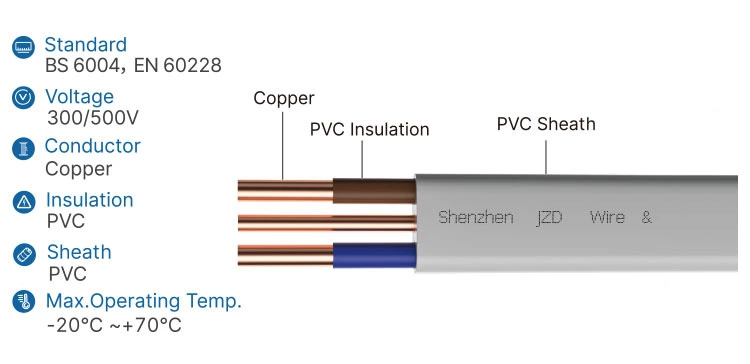

Structural Design Conductors are made of Class 1 or Class 2 annealed copper, arranged in parallel with the circuit protective conductor positioned between the two live conductors.

-

Environmental Adaptability Suitable for dry or damp environments, the cable can be fixed on walls, installed in conduits, or embedded in plasterboard and cable trays. Its flat design facilitates easy installation in trunking or pipes.

-

Eco-Friendly and Safe Manufactured with environmentally friendly materials compliant with RoHS directives. The cable meets IEC 60332.1 standards for flame retardancy and low smoke emission.

Typical Applications

-

Residential and Light Industrial Fixed Wiring Ideal for power and lighting circuits in homes, offices, and small factories, especially in dry or damp areas.

-

Industrial and Agricultural Electrical Supply Commonly used to power machinery, distribution systems, transformers, and metering devices in industrial or agricultural settings. Its robust PVC insulation and sheathing provide resistance to corrosion and minor mechanical stress.

-

Mechanical and Conduit Installations Suitable for wiring within mechanical conduits or protective tubing, such as in production lines or equipment interiors, where cables need protection against abrasion or impact.

-

Construction and Real Estate Projects Widely employed for temporary electrical setups during construction and permanent installations in residential or commercial buildings. Compliant with BS6004, CE, and RoHS standards, it meets stringent safety requirements for construction applications.

Common Mistakes to Avoid

-

Incorrect Conductor Size or Voltage Rating Undersized cables can overheat, cause voltage drops, and lead to compliance issues. Always match cable specifications to load requirements.

-

Improper Installation Excessive bending or compression may damage insulation, resulting in short circuits. Follow installation guidelines for the specific environment.

-

Ignoring Environmental Conditions Factors like temperature, chemical exposure, and mechanical stress can accelerate aging or pose safety risks. Choose cables suited to the operating conditions.

-

Using Low-Quality Cables While cheaper initially, substandard cables may wear quickly, malfunction, or fail prematurely, leading to higher long-term costs.

-

Overlooking Certifications Neglecting UL, CE, or TUV certifications may result in non-compliance or safety hazards. Always verify that cables meet relevant standards.

Tips for Optimal Selection

- Evaluate environmental conditions, mechanical demands, and electrical requirements.

- Ensure compliance with certifications and project-specific parameters.