What is UL1015 Electronic Wire?

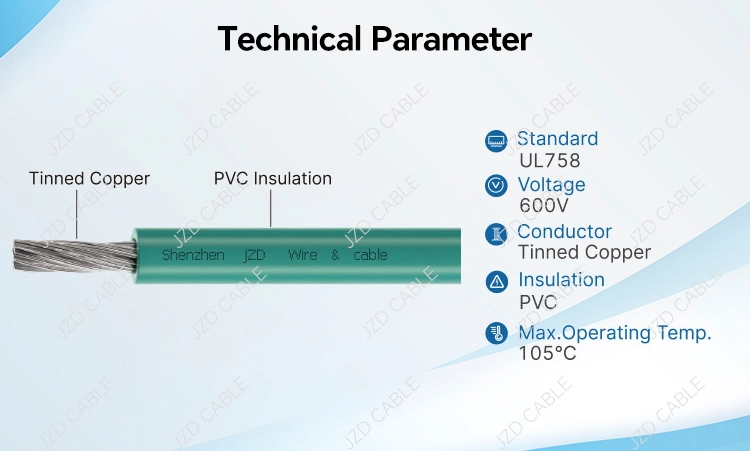

- Rated Voltage: 600V

- Temperature Rating: 105°C (221°F)

- Conductor: Typically stranded bare copper for excellent flexibility and conductivity.

- Insulation: Durable, heat-resistant PVC (Polyvinyl Chloride) that offers good resistance to oil, acids, abrasion, and moisture.

The Perfect Match: UL1015 Wire for Load Bank Applications

How to Select the Right UL1015 Wire for Your Load Bank

- Current Load (Amperage): This is the most critical factor. Always consult the load bank’s specifications for maximum output current and use an ampacity chart to select a UL1015 wire with an AWG size that can safely handle that current. When in doubt, choose a larger gauge (a smaller AWG number) for an added safety margin.

- Cable Length: Longer cable runs result in voltage drop. For distances over a few meters, you may need to upgrade to a larger AWG size to compensate for this power loss and ensure accurate testing conditions.

- Connector Compatibility: Ensure the cable’s diameter (including insulation) is compatible with the lugs, terminals, or connectors on both the load bank and the equipment under test.

Why Source Your UL1015 Cable from JZD Cable?

- Guaranteed Quality: Our UL1015 electronic wires are manufactured to meet and exceed industry standards, providing you with peace of mind and unparalleled reliability.

- Customization Options: We offer tailored solutions, including custom-cut lengths, pre-attached terminal lugs (copper connectors), and various color options for easy phase identification or organization.

- Expert Support: Our technical team is ready to help you select the perfect cable specification for your specific load bank model and application, ensuring optimal performance and safety.