When it comes to electrical wiring, THHN nylon wire stands out as a versatile and reliable choice for a variety of applications. While it is widely recognized for its role in construction, THHN wire—which stands for Thermoplastic High Heat-resistant Nylon-coated—offers much more than just powering residential and commercial buildings. Its unique properties make it suitable for diverse environments, both indoors and outdoors, as well as specialized uses in machinery and control circuits.

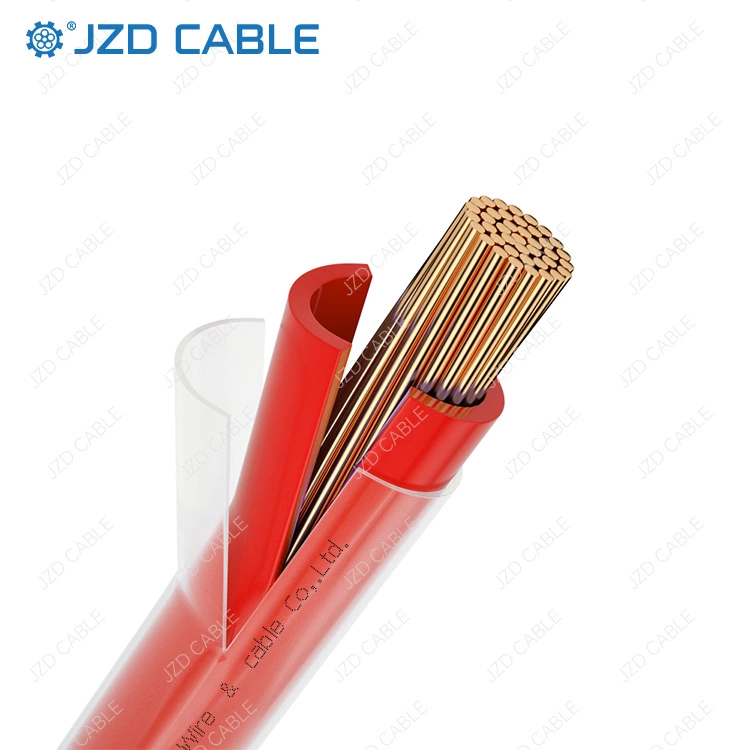

THHN wire is designed with either solid or stranded conductors, made from copper or aluminum, and insulated with PVC. The additional nylon coating enhances its durability and resistance to heat, moisture, and abrasion. Many THHN wires also carry a dual rating, such as THHN/THWN, indicating their suitability for both dry and wet conditions. This adaptability is a key reason why THHN wire is a go-to option for electricians and engineers.

Indoor Applications

Inside homes, offices, and industrial facilities, THHN wire is often used in multicore or single-core cables. Its thin yet robust insulation allows for efficient electrical performance, making it ideal for control circuits, machine tools, and appliance wiring. In many cases, multiple THHN wires are bundled together, simplifying installation and saving time for electricians. This bundling capability ensures a neat and organized wiring system without compromising safety or functionality.

Outdoor and Underground Uses

One of the standout features of THHN wire is its suitability for outdoor applications. While many building cables cannot withstand external elements, THHN wire performs reliably when installed individually or within protective conduits. However, for direct outdoor use—especially when bundled—it is recommended to upgrade to a more robust cable type, such as UFB (Underground Feeder Cable), which offers enhanced protection against environmental and chemical exposure.

For underground installations, THHN wire requires conduit for direct burial. Alternatively, UFB cables with THHN construction can be laid directly into trenches without additional piping, providing a cost-effective and efficient solution for supplying power in subterranean settings.

Beyond Construction

Apart from its common uses, THHN wire is also employed in specialized areas, including renewable energy systems, automotive wiring, and temporary power setups. Its high heat resistance and flexibility make it a preferred choice for projects demanding reliability under varying conditions.

At JZD Cable, we take pride in manufacturing top-quality THHN nylon wires that meet international standards, including UL certification. Our products are engineered to deliver exceptional performance across a broad spectrum of applications, ensuring safety, durability, and efficiency.

Whether you are an electrician, engineer, or DIY enthusiast, understanding the full range of THHN wire’s capabilities can help you make informed decisions for your projects. From indoor wiring to outdoor and underground installations, THHN wire proves to be a dependable and adaptable solution.

For more insights into high-performance electrical cables, explore JZD Cable’s product range and discover how our solutions can power your next venture.

-4-3.jpg)